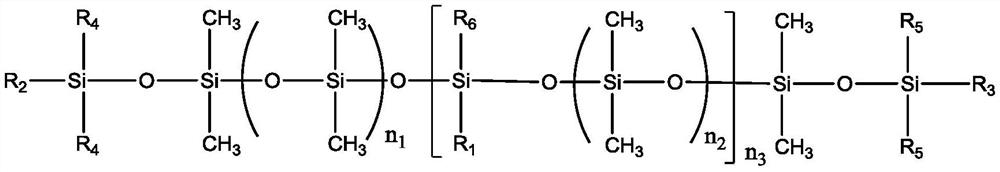

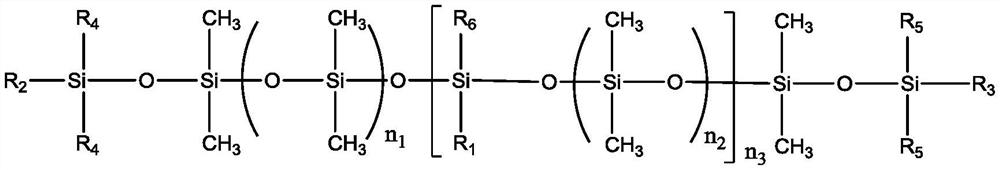

A kind of dual-curable polysiloxane and its preparation method and use

A technology of polysiloxane and hydroxyl-terminated polysiloxane, which is applied in the field of silicon materials, can solve the problems of high photocuring energy requirements, high photocuring energy of products, human body and environmental damage, etc., and achieves excellent moisture and heat aging resistance. , the effect of reducing energy and improving end capping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Take a 1000ml four-necked flask and fully dry it, add 500g of hydroxyl-terminated polysiloxane with a viscosity of 70cP, start stirring for 300r / min, vacuumize and remove water at 80°C for 60min, cool down to 50°C, add 23g of dimethoxydicarbonate Chloropropylsilane, stir for 15min, add 0.7g acetic acid, react for 3h, add 46g chloropropyltrimethoxysilane, react for 2h, remove low boiling under the condition of 100℃, 5mbar, and add 0.015 p-hydroxyanisole to the obtained product g, 20 g of sodium acrylate, stir evenly, add 2.5 g of tetramethylammonium hydroxide and heat up to 80 °C for 3 hours, then heat up to 150 °C, extract low boiling under the condition of 5mbar, filter under positive pressure to obtain product I, and its silyl hydroxyl group is tested. The residue was 0.7% and methyl acrylate was not detected.

Embodiment 2

[0048]Take a 1000ml four-necked flask and fully dry it, add 500g of hydroxyl-terminated polysiloxane with a viscosity of 200cP, turn on and stir for 300r / min, vacuumize and remove water at 100°C for 60min, cool down to 60°C, add 18g of dimethoxydicarbonate Chloropropylsilane, stir for 15min, add 0.5g phosphoric acid, react for 3h, add 38g chloropropyltrimethoxysilane, react for 2h, remove low boiling under the condition of 100℃, 5mbar, add N,N-diethyl ether to the obtained product Hydroxylamine 0.01g, sodium acrylate 16g, stir evenly, add 2.5g of tetramethylammonium hydroxide, heat up to 80 °C for 3 hours, then heat up to 145 °C, extract low boiling under 5mbar, filter under positive pressure to obtain product II, which has been tested Its silanol residue was 0.8%, and methyl acrylate was not detected.

Embodiment 3

[0050] Take a 1000ml four-necked flask and fully dry it, add 500g of hydroxyl-terminated polysiloxane with a viscosity of 100cP, start stirring for 300r / min, vacuumize and remove water at 90°C for 60min, cool down to 70°C, add 20.5g dimethoxy Dichloropropylsilane, stirred for 15min, added 0.6g phosphoric acid, reacted for 4h, added 42g of chloropropyltrimethoxysilane, reacted for 3h, removed the low boiling point under the condition of 110℃, 6mbar, and added p-hydroxyanisole to the obtained product 0.015g, 18g sodium acrylate, stir evenly, add 2.6g of tetramethylammonium hydroxide, heat up to 80°C for 4h, then heat up to 150°C, extract low boiling under 5mbar, filter under positive pressure to obtain product III, which is tested for its silicon Hydroxyl residue was 0.6%, methyl acrylate was not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com