Preparation of al by selective laser melting 2 o 3 -gdalo 3 -zro 2 Method for ternary eutectic ceramics

A laser melting and ternary eutectic technology, which is applied in the field of ceramic materials, can solve the problems of difficult forming and coarse sintered structure, and achieve the effects of fast forming speed, high forming freedom and high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

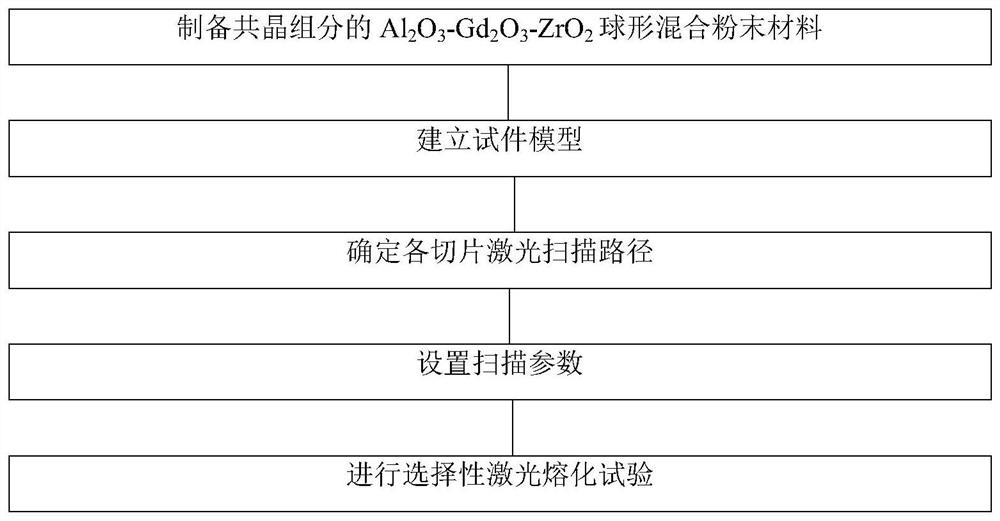

[0071] The present invention is a kind of selective laser melting to prepare Al 2 O 3 -Gd 2 O 3 -ZrO 2 The method of ternary eutectic ceramics, the specific process is:

[0072] Step 1, Preparation of Al eutectic composition 2 O 3 -Gd 2 O 3 -ZrO 2 Spherical mixed powder material:

[0073] Weigh Al with a total mass of 400g 2 O 3 Powder, Gd 2 O 3 Powder and ZrO 2 powder; the Al 2 O 3 Powder, Gd 2 O 3 Powder and ZrO 2 The ratio of powder is eutectic molar ratio Al 2 O 3 :Gd 2 O 3 :ZrO 2 =58:19:23.

[0074] Al will be weighed 2 O 3 Powder, Gd 2 O 3 Powder and ZrO 2 The powders were mixed, alcohol and polyvinyl alcohol solution were added, and the above mixture was ball-milled with a ball mill at a rotational speed of 550 rpm for 2 hours to obtain a mixture. The consumption of described alcohol is described Al 2 O 3 Powder, Gd 2 O 3 Powder and ZrO 2 10wt.% of the total mass of the powder, the dosage of the polyvinyl alcohol solution is the Al 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com