Electromagnetic shielding cement-based composite material prepared from wet-ground titanium slag and preparation method of electromagnetic shielding cement-based composite material

A technology of electromagnetic shielding and composite materials, which is applied in the field of building composite materials, can solve the problems of industrial waste accumulation and pollution, and achieve the effects of solving accumulation pollution, low comprehensive cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

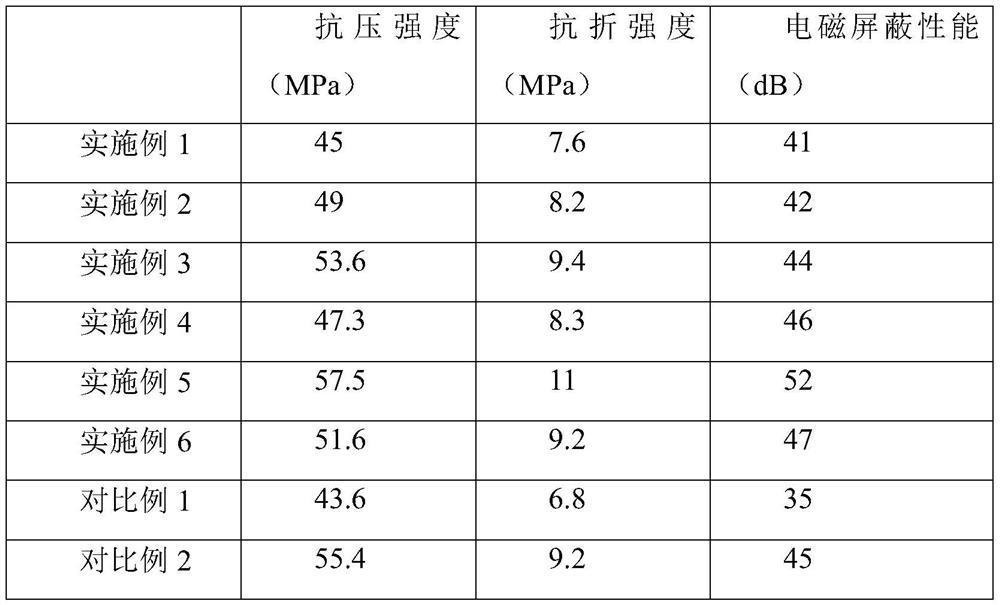

Examples

Embodiment 1

[0034] A cement-based electromagnetic shielding composite material of wet-ground titanium slag, the preparation of which comprises the following steps:

[0035] 1), get 90g of sieved titanium slag raw powder (the particle size of sieved titanium slag raw powder is 30um), set aside;

[0036] 2) Immerse and evenly disperse 2g of the treated recycled carbon fiber into 450g of water, then add 2g of dispersant, stir evenly, add 0.5g of defoamer, and then ultrasonically treat for 1.5h to obtain a carbon fiber dispersion;

[0037] 3), take 810g of Portland cement, 90g of sieved titanium slag raw powder, 9g of water reducer solution with a mass fraction of 10%, and the carbon fiber dispersion prepared in step 2), and stir evenly to obtain a wet mill Electromagnetic shielding cement-based composites prepared from titanium slag.

[0038] The above-mentioned cement-based electromagnetic shielding composite material was poured into a 160*400*40mm oil-coated mold, vibrated and scraped, an...

Embodiment 2

[0041] A cement-based electromagnetic shielding composite material of wet-ground titanium slag, the preparation of which comprises the following steps:

[0042] 1) Take 90g of titanium slag, add water and grinding aids to the titanium slag according to the water-to-material ratio of 2:1, and wet grind to obtain a wet-ground titanium slag slurry (the particle size of the titanium slag slurry after wet grinding is measured to be 4.92um) ,spare;

[0043] 2) Immerse and evenly disperse 2g of recycled carbon fibers into 270g of water, then add 2g of dispersant, stir evenly, add 0.5g of defoamer, and then ultrasonically treat for 1.5h to obtain a carbon fiber dispersion;

[0044] 3) Take 810g of Portland cement, 270g of wet-milled titanium slag slurry, 9g of a water reducer solution with a mass fraction of 10%, and the carbon fiber dispersion prepared in step 2), and stir evenly to obtain a wet-milled Electromagnetic shielding cement-based composites prepared from titanium slag.

...

Embodiment 3

[0048] A cement-based electromagnetic shielding composite material of wet-ground titanium slag, the preparation of which comprises the following steps:

[0049] 1) Take 180g of titanium slag, and wet grind the titanium slag with water and grinding aid according to the water-to-material ratio of 2:1 to obtain a wet-ground titanium slag slurry (the particle size of the titanium slag slurry after wet grinding is measured to be 4.92um) ,spare;

[0050] 2) Immerse and evenly disperse 2g of recycled carbon fiber into 90g of water, then add 2g of dispersant, stir evenly, add 0.5g of defoamer, and then ultrasonically treat for 1.5h to obtain a carbon fiber dispersion;

[0051] 3) Take 720g of Portland cement, 540g of wet-milled titanium slag slurry, 9g of a water reducer solution with a mass fraction of 10%, and the carbon fiber dispersion prepared in step 2), and stir evenly to obtain a wet-milled Electromagnetic shielding cement-based composites prepared from titanium slag.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com