High-quality granite machine-made sandstone aggregate production line and technological process thereof

A granite and production line technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of low content of finished sand and stone powder, unbalanced production, low efficiency, etc., achieve good coagulation and heterogeneity, large production capacity, and convenient The effect of water cement ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

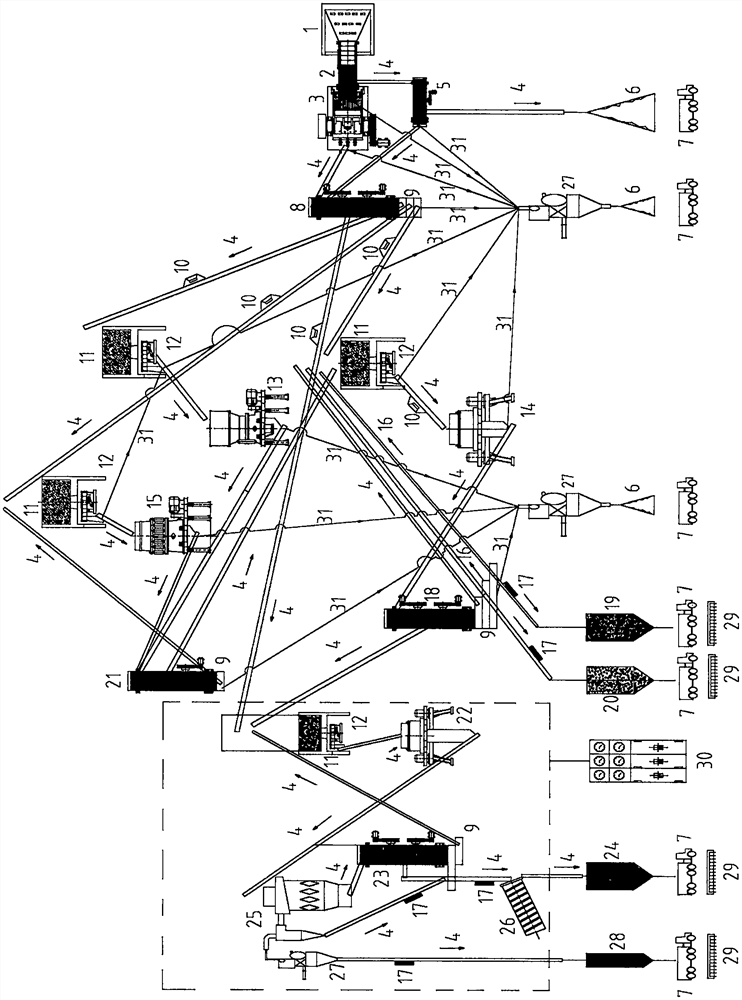

[0058] figure 1Among them, the discharge port of the raw stone silo (1) is connected with the feed end of the bar vibrating feeder (2). The discharge chute of the bar-type vibrating feeder (2) is directly connected to the feed port of the jaw crusher (3), and the discharge chute of the under-screen feeder is connected to the feeder through the one-way belt conveyor (4). The feed end of the circular vibrating desilter screen (5) is connected. The discharge chute of the circular vibrating desilting screen (5) is connected to the feeding end of the circular vibration pre-sieve (8) through the connection of the one-way belt conveyor (4), and the discharge chute of the under-screen passes through the one-way belt conveyor (4). The communication of the belt conveyor (4) is connected with the 0-10mm mud pile (6), and the 0-10mm mud is directly loaded into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com