Waterproof, breathable and bacteriostatic compound non-woven fabric and preparation method and application thereof

A waterproof, breathable, non-woven technology, applied in textiles and papermaking, non-woven fabrics, rayon manufacturing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

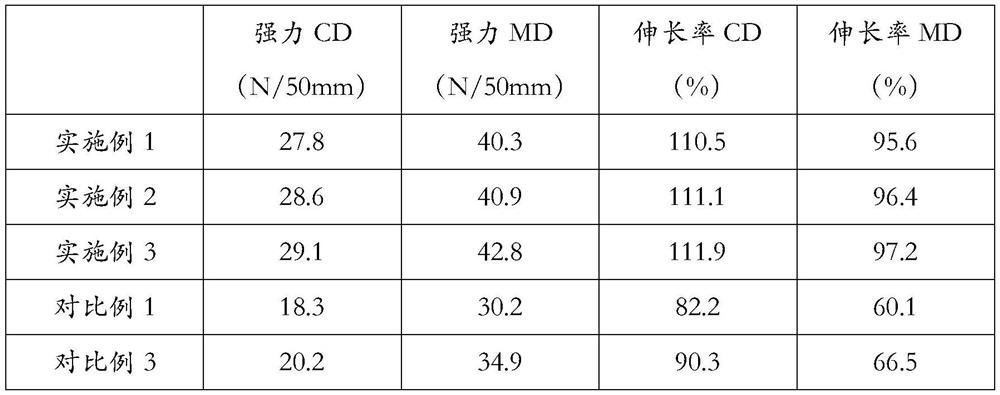

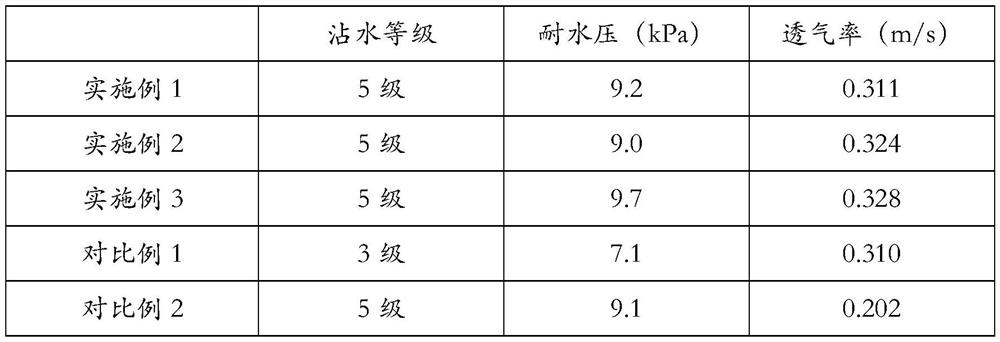

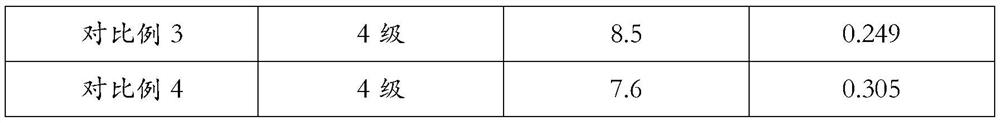

Examples

Embodiment 1

[0042] A preparation method of a waterproof and breathable composite non-woven fabric. First, polyacrylonitrile, polyvinylidene fluoride, fillers, and water-soluble porogen are mixed and melted, and then sprayed out through a spinneret, air-drawn, formed into a web, and hot-pressed. Bonding, water immersion to remove the porogen, namely the composite non-woven fabric; wherein, the filler is prepared by the following method:

[0043] (1) earlier take zinc acetate, sodium tripolyphosphate, sodium hydroxide and porous tourmaline as raw material to make zinc oxide-tourmaline complex through solid phase reaction;

[0044] (2) Carry out epoxy modification to zinc oxide-tourmaline complex body then, then react with amino-terminated fluoropolymer, obtain modified complex body;

[0045] (3) Finally, immerse the modified complex in 1-allyl-3-methylimidazolium tetrafluoroborate for surface modification to obtain the filler.

[0046] The mass ratio of polyacrylonitrile, polyvinylidene fl...

Embodiment 2

[0063] A preparation method of a waterproof and breathable composite non-woven fabric. First, polyacrylonitrile, polyvinylidene fluoride, fillers, and water-soluble porogen are mixed and melted, and then sprayed out through a spinneret, air-drawn, formed into a web, and hot-pressed. Bonding, water immersion to remove the porogen, namely the composite non-woven fabric; wherein, the filler is prepared by the following method:

[0064] (1) earlier take zinc acetate, sodium tripolyphosphate, sodium hydroxide and porous tourmaline as raw material to make zinc oxide-tourmaline complex through solid phase reaction;

[0065] (2) Carry out epoxy modification to zinc oxide-tourmaline complex body then, then react with amino-terminated fluoropolymer, obtain modified complex body;

[0066] (3) Finally, immerse the modified complex in 1-allyl-3-methylimidazolium tetrafluoroborate for surface modification to obtain the filler.

[0067] The mass ratio of polyacrylonitrile, polyvinylidene fl...

Embodiment 3

[0084] A preparation method of a waterproof and breathable composite non-woven fabric. First, polyacrylonitrile, polyvinylidene fluoride, fillers, and water-soluble porogen are mixed and melted, and then sprayed out through a spinneret, air-drawn, formed into a web, and hot-pressed. Bonding, water immersion to remove the porogen, namely the composite non-woven fabric; wherein, the filler is prepared by the following method:

[0085] (1) earlier take zinc acetate, sodium tripolyphosphate, sodium hydroxide and porous tourmaline as raw material to make zinc oxide-tourmaline complex through solid phase reaction;

[0086] (2) Carry out epoxy modification to zinc oxide-tourmaline complex body then, then react with amino-terminated fluoropolymer, obtain modified complex body;

[0087] (3) Finally, immerse the modified complex in 1-allyl-3-methylimidazolium tetrafluoroborate for surface modification to obtain the filler.

[0088] The mass ratio of polyacrylonitrile, polyvinylidene fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com