Method for optimizing grain size and uniformity of tantalum plate

A technology of grain size and uniformity, applied in the field of optimizing the grain size and uniformity of tantalum plates, can solve the problems of uneven distribution of plastic deformation, low total processing rate of medium and thick plate rolling, coarse grains, etc., to avoid problems such as Defects of insufficient grain breakage, the effect of improving the degree of grain breakage and improving the uniformity of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

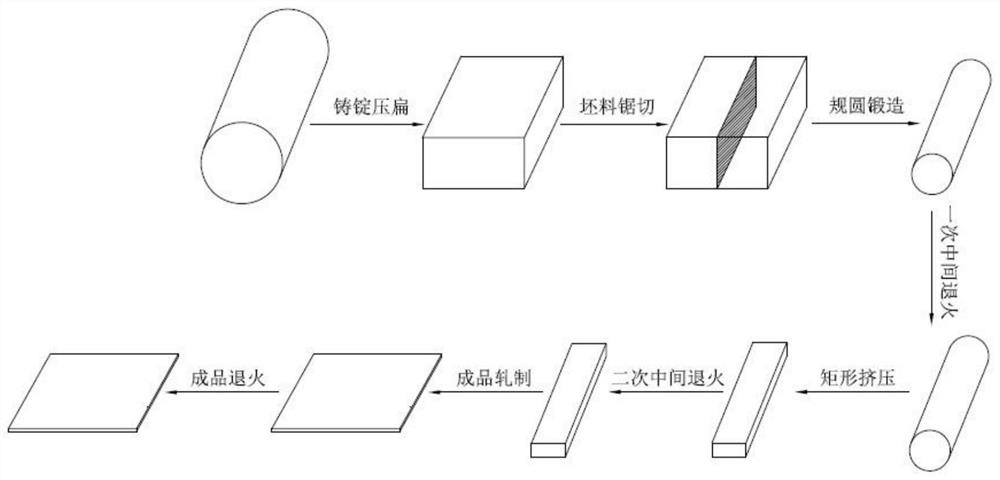

[0042] Such as figure 1 As shown, a method for optimizing the grain size and uniformity of the tantalum plate in this embodiment includes the following steps:

[0043] Step 1. Under room temperature, use a fast forging machine with a forging ratio of 1.0 to flatten an electron beam-melted tantalum ingot with a circular cross-section and a circular diameter of 220mm to obtain a size of 137×274×L 1 mm tantalum billet with a rectangular cross-section; the length of the rectangle is 274 mm and the width is 137 mm; the tantalum ingot is a tantalum ingot melted by electron beams at least twice, and the aspect ratio of the tantalum ingot is ≥ 1.2 If the forging ratio is 1.0, the cross-sectional area remains unchanged before and after forging, that is, the cross-sectional area of the rectangular tantalum billet is equal to the cross-sectional area of the circular tantalum ingot; the room temperature is 20°C to 25°C ;

[0044] Step 2. Sawing the tantalum blank whose cross-section...

Embodiment 2

[0053] Such as figure 1 As shown, a method for optimizing the grain size and uniformity of the tantalum plate in this embodiment includes the following steps:

[0054] Step 1. Under room temperature, use a fast forging machine with a forging ratio of 1.0 to flatten an electron beam melted tantalum ingot with a circular cross-section and a circular diameter of 240mm to obtain a size of 150×300×L 1 mm tantalum billet with a rectangular cross section; the length of the rectangle is 300 mm and the width is 150 mm; the tantalum ingot is a tantalum ingot melted by electron beam at least twice, and the aspect ratio of the tantalum ingot is ≥ 1.2 If the forging ratio is 1.0, the cross-sectional area remains unchanged before and after forging, that is, the cross-sectional area of the rectangular tantalum billet is equal to the cross-sectional area of the circular tantalum ingot; the room temperature is 20°C to 25°C ;

[0055] Step 2. Sawing the tantalum blank whose section shape ...

Embodiment 3

[0064] Such as figure 1 As shown, a method for optimizing the grain size and uniformity of the tantalum plate in this embodiment includes the following steps:

[0065] Step 1. Under room temperature, use a fast forging machine with a forging ratio of 1.0 to flatten an electron beam-melted tantalum ingot with a circular cross-section and a circular diameter of 280mm to obtain a size of 175×350×L 1 mm tantalum billet with a rectangular cross section; the length of the rectangle is 350 mm and the width is 175 mm; the tantalum ingot is a tantalum ingot melted by electron beams at least twice, and the aspect ratio of the tantalum ingot is ≥ 1.2 If the forging ratio is 1.0, the cross-sectional area remains unchanged before and after forging, that is, the cross-sectional area of the rectangular tantalum billet is equal to the cross-sectional area of the circular tantalum ingot; the room temperature is 20°C to 25°C ;

[0066] Step 2. Sawing the rectangular tantalum blank with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com