Thick and heavy hot-rolled H-shaped steel capable of inhibiting grain growth and production method thereof

A technology for inhibiting grain growth and production methods, applied in temperature control, metal rolling, etc., to achieve the effect of inhibiting grain growth and enhancing effective regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

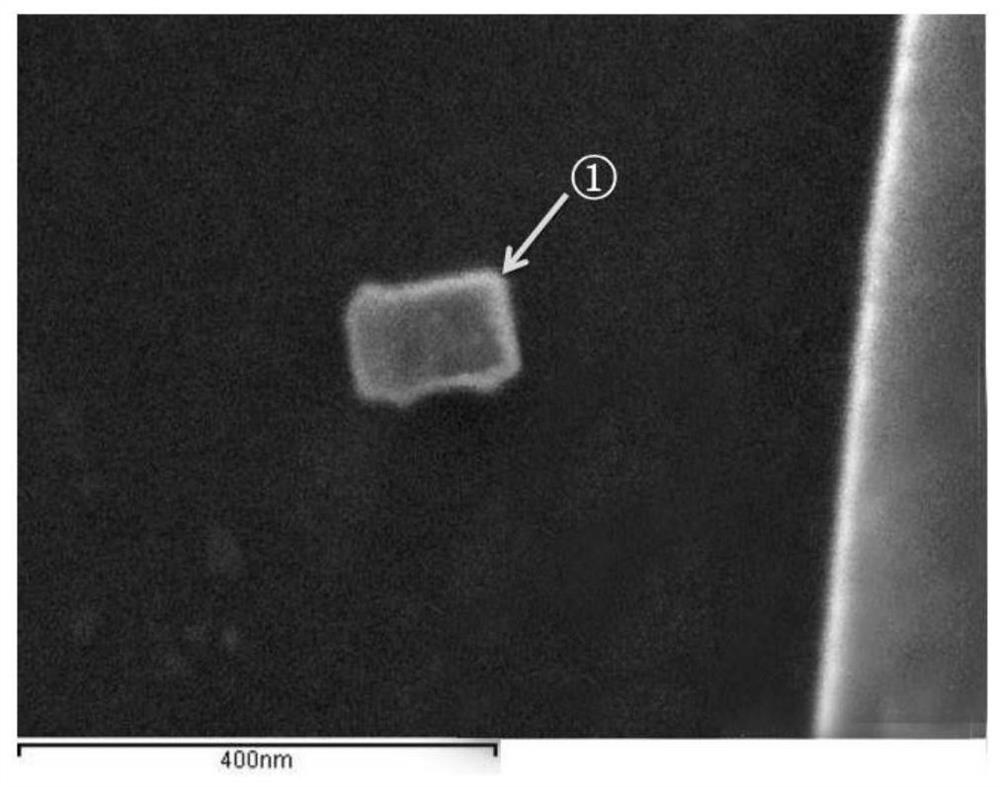

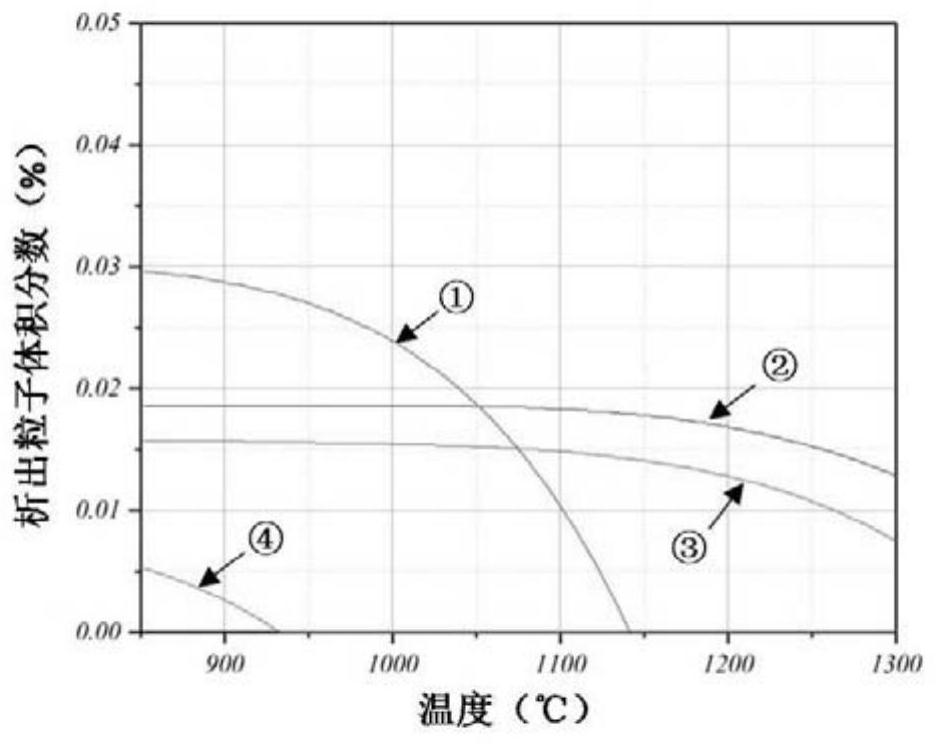

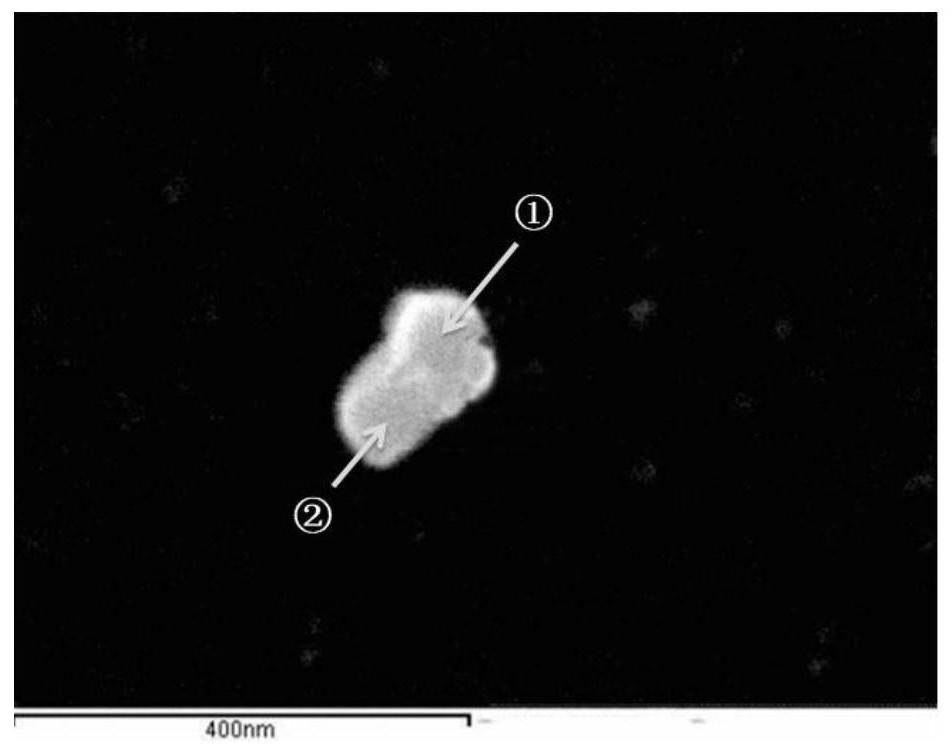

[0041] For thick hot-rolled H-beams, it is difficult to control the austenite grain size during heating and cooling only by microalloying of Nb. Theory and experiments prove that TiN particles have high thermal stability and can effectively control the grain growth of austenite during heating and rough rolling. Therefore, it is necessary to adopt Ti / Nb composite microalloying. For thick hot-rolled H-beams, the addition of microalloying element Ti will form rectangular particles with edges and corners due to the coherent interface between TiN particles and the matrix, such as figure 1 shown. The edges and corners of such rectangular particles will have a large stress concentration, which will cause cracks in the continuous casting slab due to external stress and thermal stress during the cooling process of the continuous casting slab, resulting in the failure of Ti / Nb composite microalloying in the actual production process. technical challenge. Aiming at this technical prob...

Embodiment 2

[0053] A thick hot-rolled H-shaped steel that inhibits grain growth and its production method in this embodiment are basically the same as in Embodiment 1, except that it includes the following components in weight percentage: C: 0.05%; Si: 0.50%, Mn: 1.60%; Nb: 0.02%; Ti: 0.015%; N: 0.003%, and the balance is iron and other impurities. In this embodiment, the thickness of the flange of the finished hot-rolled H-shaped steel is 150mm.

[0054] A production method of thick hot-rolled H-shaped steel that suppresses grain growth in this embodiment, the basic process is consistent with that of Embodiment 1, the difference is that in this embodiment, the continuous casting slab is controlled during the continuous casting process. The cooling rate is 4.5°C / s, the volume fraction of TiN, NbC, and Ti+Nb composite particles precipitated inside the slab is 0.06%, and the average diameter of the corresponding second phase particles is 45nm.

[0055] When baking the submerged nozzle in t...

Embodiment 3

[0060] A thick hot-rolled H-shaped steel that inhibits grain growth and its production method in this embodiment are basically the same as in Embodiment 1, except that it includes the following components in weight percentage: C: 0.14%; Si: 0.31%, Mn: 1.32%; Nb: 0.032%; Ti: 0.011%; N: 0.004%, and the balance is iron and other impurities. In this embodiment, the thickness of the flange of the finished hot-rolled H-shaped steel is 100mm.

[0061] A production method of thick hot-rolled H-shaped steel that suppresses grain growth in this embodiment, the basic process is consistent with that of Embodiment 1, the difference is that in this embodiment, the continuous casting slab is controlled during the continuous casting process. The cooling rate is 3.9°C / s, the volume fraction of TiN, NbC, and Ti+Nb composite particles precipitated inside the slab is 0.052%, and the average diameter of the corresponding second phase particles is 40nm.

[0062] When baking the submerged nozzle in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com