Biodegradable medical zinc-tin alloy as well as preparation method and application thereof

A zinc-tin and alloy technology, applied in the field of medical materials, can solve the problems of inflammatory reaction, reduce the dehydrogenation and excessive magnesium alloy, and slow the degradation rate, and achieve the effects of excellent corrosion resistance, improved mechanical properties, and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

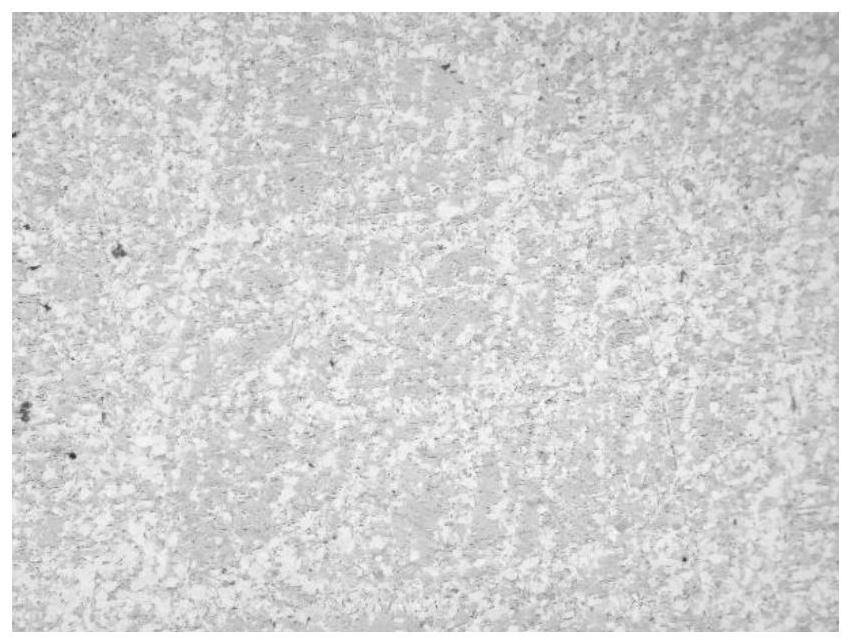

Embodiment 1

[0041] The Zn-1Sn binary alloy ingot material was prepared by using the existing traditional resistance furnace alloy smelting and casting process. The raw materials used in the test were zinc ingots (purity above 99.95%) produced by Wenxi County Metal Co., Ltd. and China Metallurgical Metal Research Institute. The high-purity metal tin nuggets (purity above 99.995%) produced by the Institute, the mass of the tin ingot is 10g, the mass of the zinc ingot is 990g, the mass ratio is 1:99, and the total mass is 1000g. Wash the furnace once with pure zinc before smelting zinc alloy to avoid the influence of other elements. The specific preparation process: put pure zinc metal and pure tin metal into a smelted graphite crucible, put the crucible into a melting furnace for melting, and the melting temperature is 500 ℃, after the added metal is melted, keep it warm for about 10 minutes. During this process, stir continuously, remove slag, and cast it into the mold. The casting temperat...

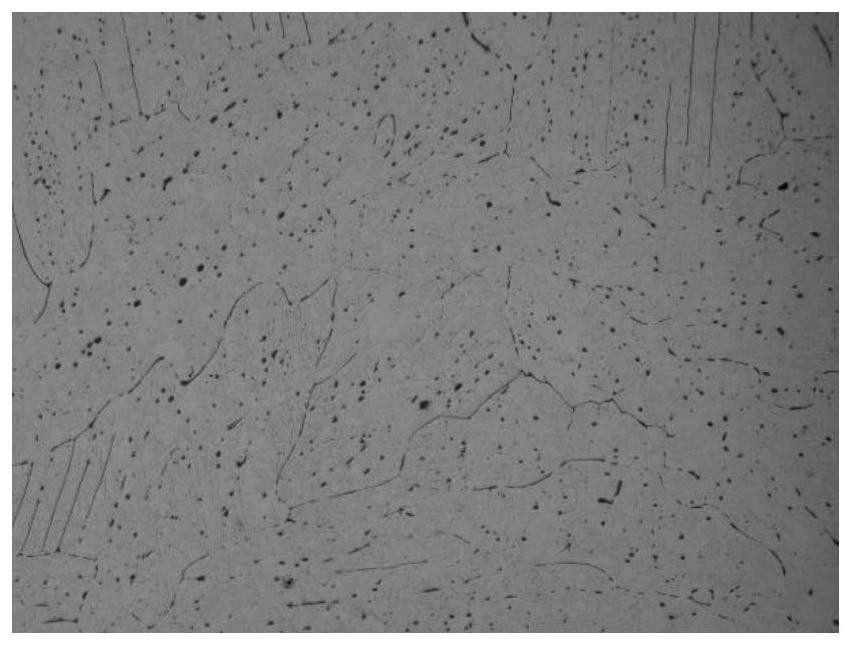

Embodiment 2

[0043] The Zn-2Sn binary alloy ingot material was prepared by using the existing traditional resistance furnace alloy smelting and casting process. The raw materials used in the test were zinc ingots (purity above 99.95%) produced by Wenxi County Metal Co., Ltd. and China Metallurgical Metal Research Institute. The high-purity metal tin nuggets (with a purity of 99.995%) produced by the Institute, in which the mass of the tin ingot is 20g, the mass of the zinc ingot is 980g, the mass ratio is 1:49, and the total mass is 1000g. Wash the furnace once with pure zinc before smelting zinc alloy to avoid the influence of other elements. The specific preparation process: put pure zinc metal and pure tin metal into a smelted graphite crucible, put the crucible into a melting furnace for melting, and the melting temperature is 500 ℃, after the added metal is melted, keep it warm for about 10 minutes. During this process, stir continuously, remove slag, and cast it into the mold. The cas...

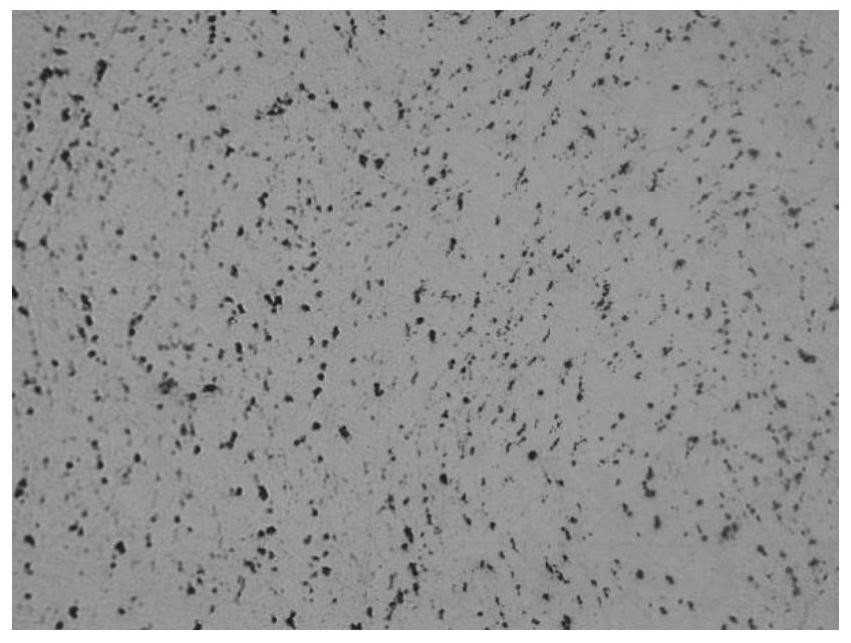

Embodiment 3

[0045] The Zn-5Sn binary alloy ingot material was prepared by using the existing traditional resistance furnace alloy smelting and casting process. The raw materials used in the test were zinc ingots (purity above 99.95%) produced by Wenxi County Metal Co., Ltd. and China Metallurgical Metal Research Institute. High-purity metal tin nuggets (purity above 99.995%) produced by the institute, the mass of tin ingots is 50g, the mass of zinc ingots is 950g, the mass ratio is 1:19, and the total mass is 1000g. Wash the furnace once with pure zinc before smelting zinc alloy to avoid the influence of other elements. The specific preparation process: put pure zinc metal and pure tin metal into a smelted graphite crucible, put the crucible into a melting furnace for melting, and the melting temperature is 500 ℃, after the added metal is melted, keep it warm for about 10 minutes. During this process, stir continuously, remove slag, and cast it into the mold. The casting temperature is 440...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com