Comprehensive recovery method for flotation of silver concentrate from zinc hydrometallurgy acid leaching residues

A technology of acid leaching and wet zinc smelting, which is applied in the direction of chemical instruments and methods, iron compounds, process efficiency improvement, etc., can solve the unseen problems of preparing iron phosphate, etc., reduce outsourcing, less investment, and improve comprehensive Effects of Recycling and Recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

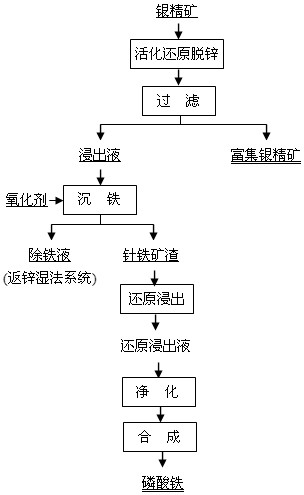

Image

Examples

Embodiment 1

[0042] A. Activation-reduction dezincification: mix the silver concentrate slurry obtained by flotation of acidic leaching slag from wet smelting zinc and zinc electrolysis waste liquid in the leaching tank at a volume ratio of 1:1.2, and pour it to the plate with pinholes at the bottom of the leaching tank. The flue gas after the zinc concentrate fluidized furnace roasting and dust collection treatment is slowly passed into the pipe, the dezincification temperature is 90°C, the dezincification time is 12 hours, and the amount of sulfur dioxide introduced is 0.8×10 - 2 mol / g, Mn in zinc electrolysis waste solution 2+ The content is 12g / L, and the terminal acidity is 10g / L.

[0043] B. Goethite method for iron precipitation: the leaching solution obtained in step A is used for iron precipitation by goethite method, the oxidant is oxygen, pH=2.5, Fe in the solution after iron precipitation 全 =3g / L, end point of iron sinking Fe 2+ It is 1.0g / L, the iron precipitation temperatu...

Embodiment 2

[0048] A. Activation reduction dezincification: mix the silver concentrate slurry obtained by flotation of acidic leaching slag from wet smelting zinc and zinc electrolysis waste liquid in the leaching tank at a volume ratio of 1:1.8, and pour it into the plate with pinholes at the bottom of the leaching tank. The flue gas after the zinc concentrate fluidized furnace roasting and dust collection treatment is slowly introduced into the pipe, the dezincification temperature is 75°C, the dezincification time is 3 hours, and the amount of sulfur dioxide introduced is 2.5×10 - 2 mol / g, Mn in zinc electrolysis waste solution 2+ The content is 4g / L, and the terminal acidity is controlled at 25g / L.

[0049] B. Goethite method for iron precipitation: use the leach solution obtained in step A to use goethite method for iron precipitation, the oxidant is air, pH=2.8, Fe in the solution after iron precipitation 全 =5g / L, end point of iron sinking Fe 2+ It is 2.4g / L, the iron precipitati...

Embodiment 3

[0054] A. Activation reduction dezincification: mix the silver concentrate slurry obtained by flotation of acid leaching slag from wet smelting zinc electrolysis and zinc electrolysis waste liquid in the leaching tank at a volume ratio of 1:1.5, and pour it to the plate with pinholes at the bottom of the leaching tank. The flue gas after the zinc concentrate fluidized furnace roasting and dust collection treatment is slowly passed into the pipe, the dezincification temperature is 80°C, the dezincification time is 6 hours, and the sulfur dioxide feed rate is 1.5×10 - 2 mol / g, Mn in zinc electrolysis waste solution 2+ The content is 8g / L, and the terminal acidity is controlled at 15g / L.

[0055] B. Goethite method for iron precipitation: use the leach solution obtained in step A to use the goethite method for iron precipitation, the oxidant is 7 air, pH=2.7, Fe in the solution after iron precipitation 全 =4g / L, end point of iron sinking Fe 2+ It is 1.4g / L, the iron precipitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com