A method for reusing scrapped wheel groove taper milling cutter

A taper and milling cutter technology, applied in the field of wheel groove milling cutter reuse, can solve the problems of unreusable, small end chipping, scrapping, etc., to reduce the amount of outsourcing, improve the tool strength, and turn waste into treasure. Manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

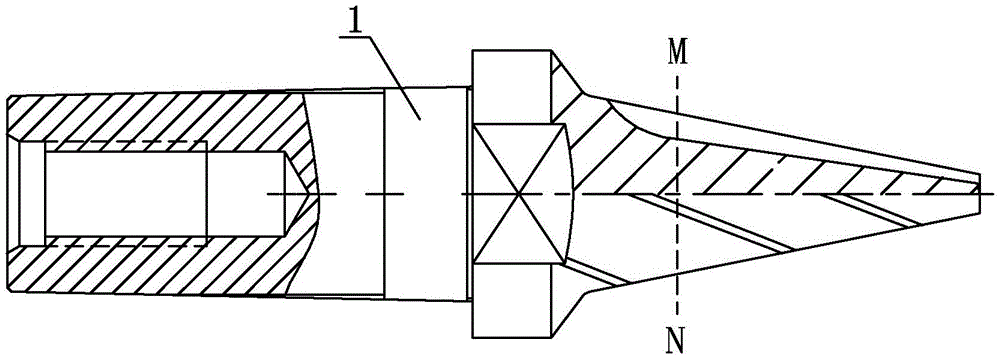

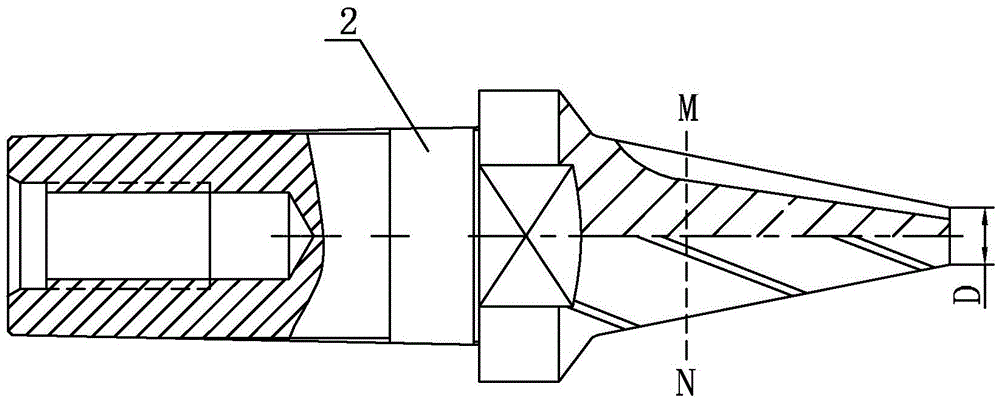

[0011] Specific implementation mode one: combine Figure 1-Figure 5 Describe this embodiment mode, a kind of scrapped wheel groove taper milling cutter recycling method of this embodiment mode is to realize according to the following steps:

[0012] 1. Determine the machining allowance, and inspect each wheel groove taper milling cutter 1 to be reformed on the magnifying instrument to ensure that the diameter at the measurement line of the standard wheel groove taper milling cutter is the same as the diameter at the measurement line MN of the wheel groove taper milling cutter to be modified The difference in diameter is less than 0.05mm, so as to ensure that the wheel groove taper milling cutter to be modified has enough margin for processing, so that the outline dimension of the modified wheel groove taper milling cutter meets the processing accuracy requirements;

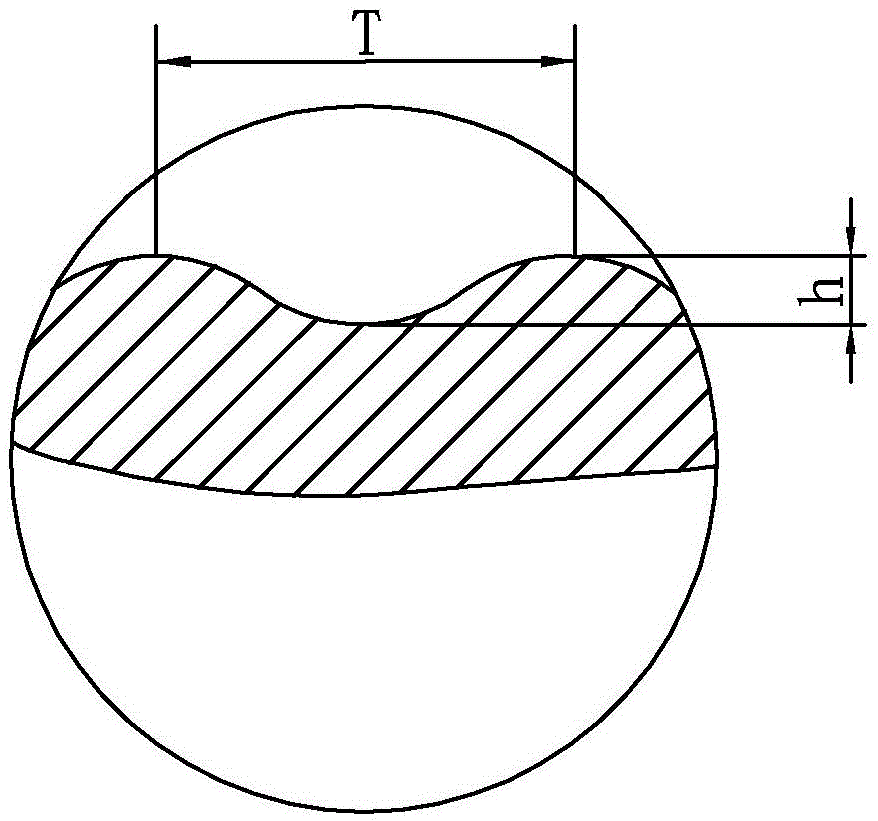

[0013] 2. For the modification of the small end of the wheel groove taper milling cutter, use a CNC wire cuttin...

specific Embodiment approach 2

[0016] Embodiment 2: It also includes step 5, said step 5 coating the restructured wheel groove taper milling cutter 2 obtained in step 4 with a TiAlN nanocomposite coating. With such arrangement, the cutting tool with the coating has high wear resistance and low friction coefficient, which can increase the service life of the cutting tool. Other steps and parameters are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com