Continuous industrial production method of high-purity bisphenol A-bis (diphenyl phosphate)

A technology of diphenyl phosphate ester and production method, which is applied in the fields of chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., and can solve the problem of low production yield, harm to human health, and chemical plant bubbles. Problems such as dripping and leaking can be avoided, and the effect of reducing production costs, improving labor efficiency, and reducing labor intensity can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

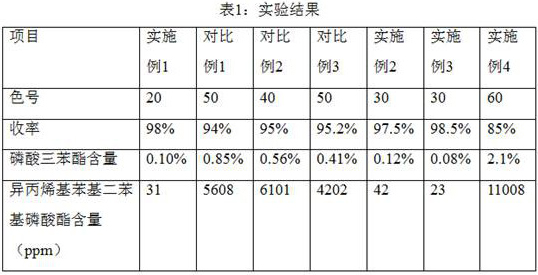

Examples

Embodiment 1

[0030] A continuous industrial production method of high-purity bisphenol A-bis(diphenyl phosphate), specifically comprising the following steps:

[0031] 1. Multi-level cross-linking reaction:

[0032] Phosphorus oxychloride 4500Kg / h, magnesium chloride 20Kg / h, bisphenol A 1200kg / h are continuously fed into the pre-mixing tank in proportion, and after heating and pre-mixing in the pre-mixing tank, the reaction liquid in the pre-mixing tank is continuously The feeding method flows from the first-stage reactor to the fourth-stage reactor, the reaction temperature of the first-stage reactor is 80-85°C, the reaction temperature of the second-stage reactor is 90-100°C, and the reaction temperature of the third-stage reactor The reaction temperature is 100-110°C, the reaction temperature of the fourth-stage reactor is 110-120°C, the residence time of materials in each reactor is 2 hours, and the reaction pressure is controlled at -0.015mpa~-0.02mpa.

[0033]The reaction liquid flo...

Embodiment 2

[0060] Substantially the same as Example 1, the phosphorus oxychloride amount is changed into 5500kg / h, and other reaction conditions are constant.

Embodiment 3

[0062] Basically the same as in Example 1, the ratio of the two feeds of bisphenol A is changed to 70% of the total amount of bisphenol A added for the first time (that is, the flow rate of the first part of bisphenol A that first participates in the reaction is 1050kg / h), Add the remaining 30% for the second time (that is, the flow rate of bisphenol A participating in the reaction in the second part of the later stage is 450kg / h), and the other reaction conditions remain unchanged, and the test is carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com