Method used for forming of thick plate blanks from high-temperature direct forging of TiAl alloy powder

A technology of alloy powder and thick slab, which is applied in the field of TiAl alloy thermal processing, can solve the problems of coarse grain, shrinkage porosity, and deterioration of alloy properties, so as to reduce the formation of B2 phase, reduce the formation of β phase, and improve the mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

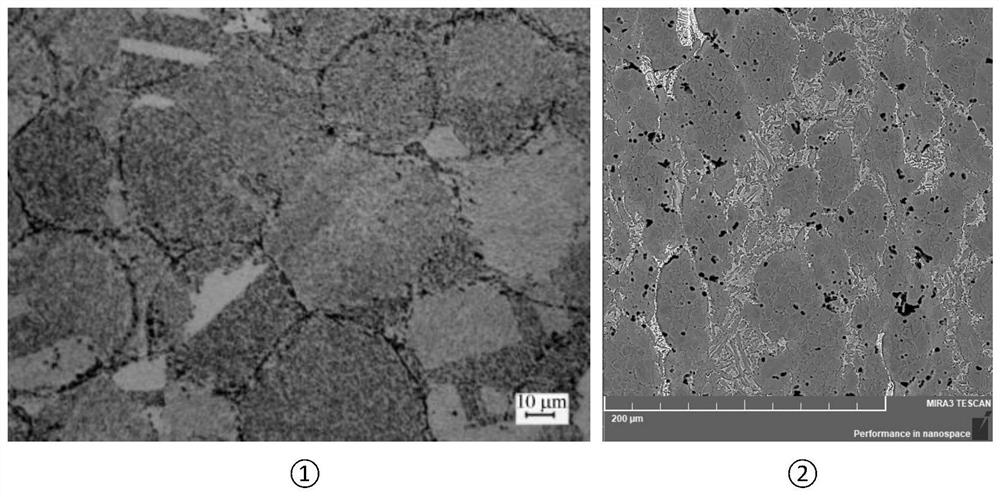

Embodiment 1

[0039] The specific steps of the method for forming a thick plate blank by direct forging of powder at high temperature are as follows:

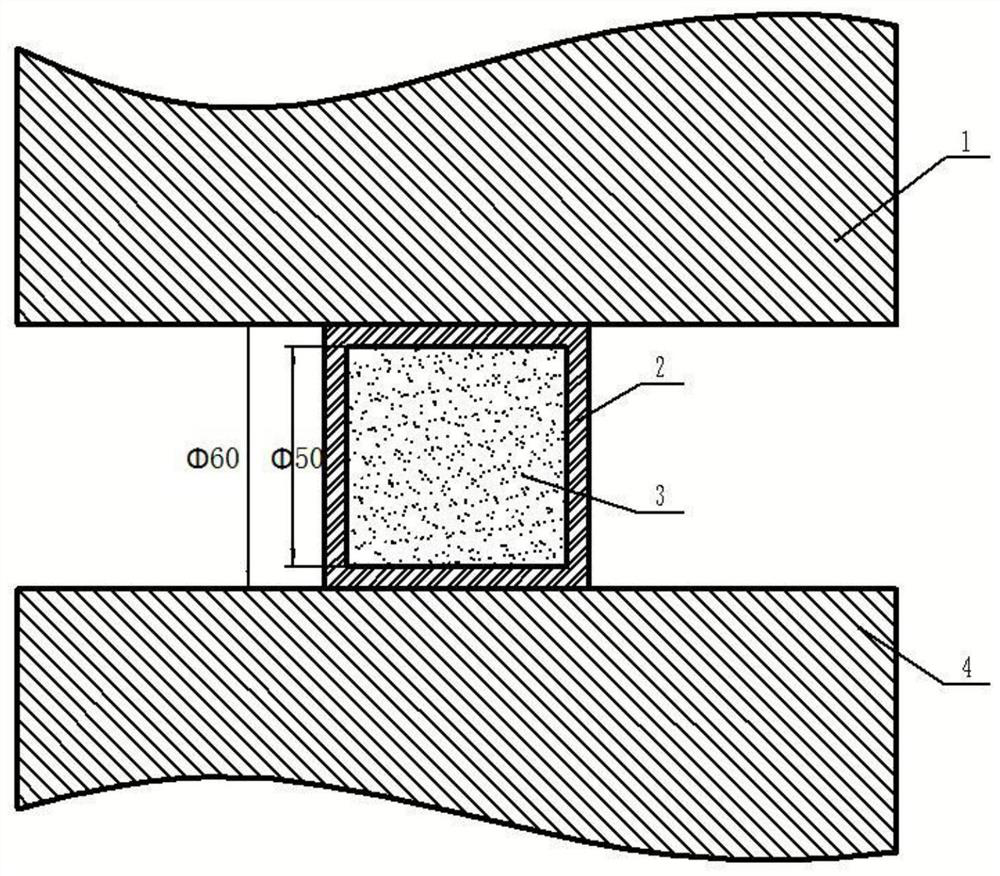

[0040] Step 1, package design:

[0041] According to the size of the thick plate blank to be processed, the hollow cylindrical sheath is made, and the wall thickness of the sheath is t 0 It is 5mm, and the material is pure titanium. The outer diameter D of the sheath is 60mm.

[0042] Step 2. Production of powder ingot:

[0043] Fill the alloy powder 3 in the bag, place it on a vibrating table for processing, replenish the alloy powder 3 while vibrating, and the vibrating time is five minutes. Then vacuum the filled bag to 8×10 -3 Pa, then heated to 400°C, kept warm, and then evacuated to 6×10 -3 Pa uses a hydrogen-oxygen tube sealing machine to seal and weld the degassing port to obtain a cylindrical powder ingot.

[0044] Step 3, heating the powder ingot:

[0045] Put the powder ingot in a high-temperature furnace and heat it to 1400°...

Embodiment 2

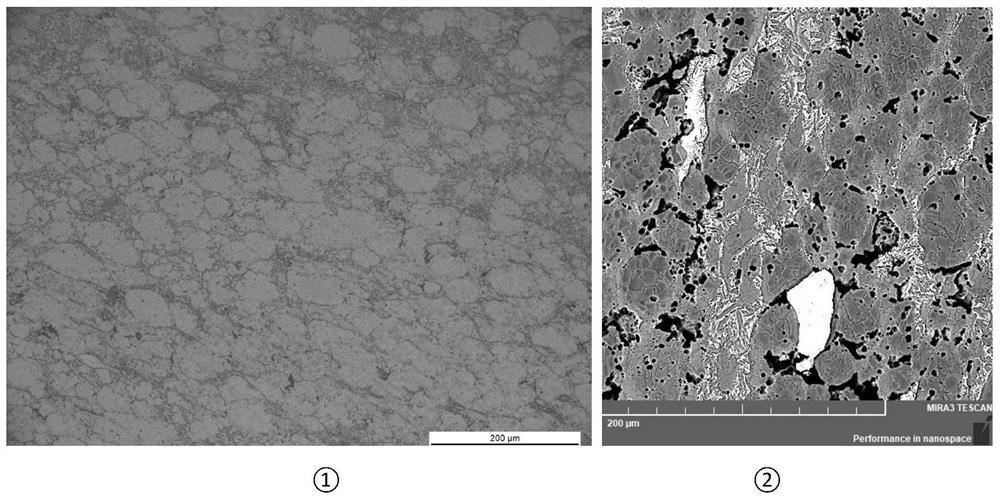

[0052] The method for forming a thick plate blank by direct forging of powder at high temperature is characterized in that the steps of the method are:

[0053] Step 1. Package design

[0054] According to the size calculation of the thick plate blank, the cylindrical sheath is made, and the wall thickness of the sheath is t 0 It is 5mm, and the material is pure titanium. The outer diameter of the sheath is 60mm.

[0055] Step 2. Production of powder ingot

[0056] Fill the alloy powder ③ in the bag, put it on the vibrating table for processing, replenish the powder while vibrating, and the vibrating time is five minutes. Then vacuum the bag to 8×10 -3 Pa, then heated to 400°C, kept warm, and then evacuated to 6×10 -3 Pa uses a hydrogen-oxygen tube sealing machine to seal and weld the degassing port to obtain a cylindrical powder ingot.

[0057] Step 3. Heating the powder billet

[0058] Put the powder ingot in a high-temperature furnace and heat it to 1420°C and then k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com