A high density fe-n 4 Preparation method and application of active site oxygen reduction electrocatalyst

A technology of active sites and electrocatalysts, applied in the field of preparation of high-density Fe-N4 active site oxygen reduction electrocatalysts, can solve the problems that the catalytic activity of electrocatalysts cannot meet the activity requirements of PEMFCs, and it is difficult to apply proton exchange membrane fuel cells. , to achieve the effect of improving oxygen reduction catalytic activity, excellent oxygen reduction activity, and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 40mg ZrOCl 2 ·8H 2 O was dispersed in 8 mL of DMF solution, 650 mg benzoic acid, 20 mg Heme, 30 mg meso-tetrakis (4-carboxyphenyl) porphine (TCPP), 10 mg meso-tetrakis (4-carboxyphenyl) porphine iron chloride (Fe -TCPP), ultrasonication at 25°C for 30min, reaction at 120°C for 12h, suction filtration, washing until the filtrate was colorless, and drying at 65°C to obtain the precursor of the electrocatalyst, denoted as 20-Heme@Fe 10 -PCN-222, then the precursor was heated at a rate of 5°C / min to 700°C and then kept at a constant temperature for 2 hours, and finally a black powder solid was obtained, denoted as 20-Heme@Fe 10 -PCN-222-700.

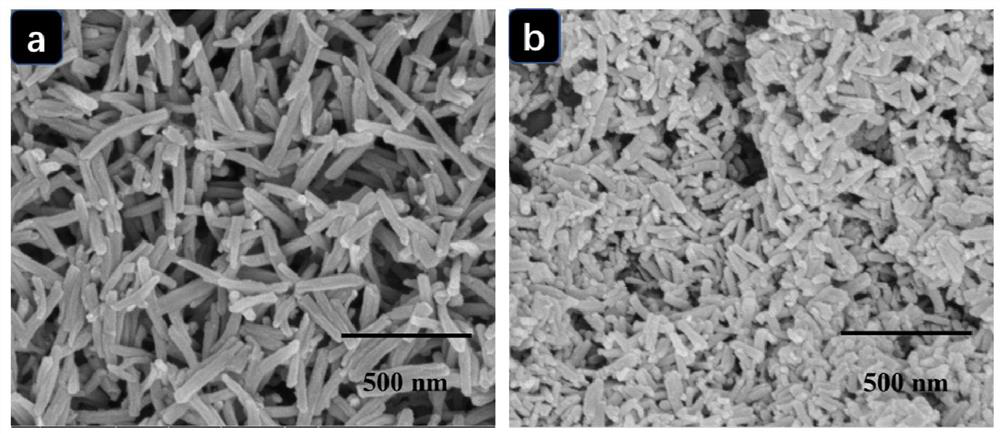

[0031] Such as figure 1 , the prepared electrocatalyst precursor 20-Heme@Fe obtained in Example 1 10 - PCN-222 is rod-shaped and uniform in size, and is consistent with the initial PCN-222 morphology of the electrocatalyst precursor obtained in Example 2, but its size is reduced.

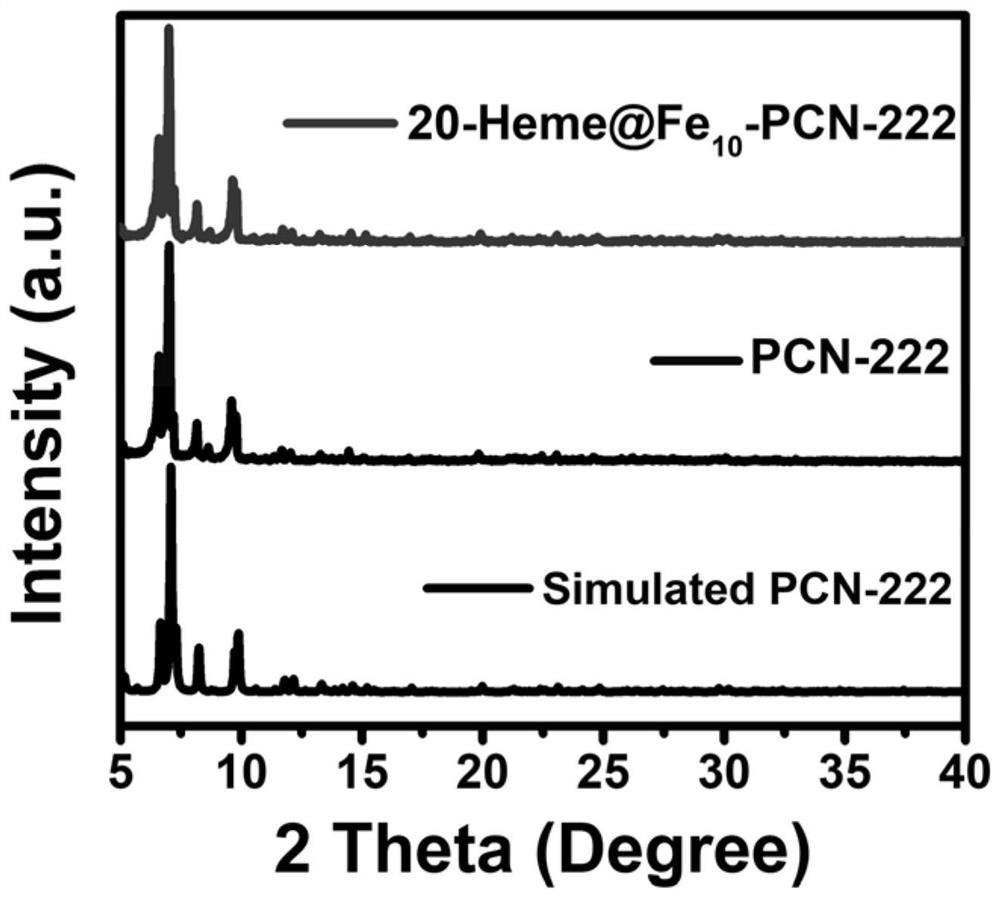

[0032] Such as figure 2 , the XRD diffraction ...

Embodiment 2

[0038] 40mg ZrOCl 2 ·8H 2 O was dispersed in 8 mL of DMF solution, added 650 mg benzoic acid, 10 mg Heme, 40 mg TCPP, ultrasonicated at 25 °C for 30 min, reacted at 120 °C for 12 h, filtered with suction, washed until the filtrate was colorless, and dried at 65 °C to obtain an electrocatalyst 10-Heme@PCN-222, and then the precursor was heated at a rate of 5°C / min to 700°C and then kept at a constant temperature for 2 hours to obtain a black powder solid, which was named 10-Heme@PCN-222-700.

Embodiment 3

[0040] 40mg ZrOCl 2 ·8H 2 O was dispersed in 8 mL of DMF solution, added 650 mg benzoic acid, 20 mg Heme, 40 mg TCPP, ultrasonicated at 25 °C for 30 min, reacted at 120 °C for 12 h, filtered with suction, washed until the filtrate was colorless, and dried at 65 °C to obtain an electrocatalyst 20-Heme@PCN-222, and then the precursor was heated at a rate of 5°C / min to 700°C and then kept at a constant temperature for 2 hours to obtain a black powder solid, which was named 20-Heme@PCN-222-700.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com