Image sensor and manufacturing method thereof

A technology of image sensor and manufacturing method, applied in the field of image sensor, capable of solving problems such as large dark current, pixel optical crosstalk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

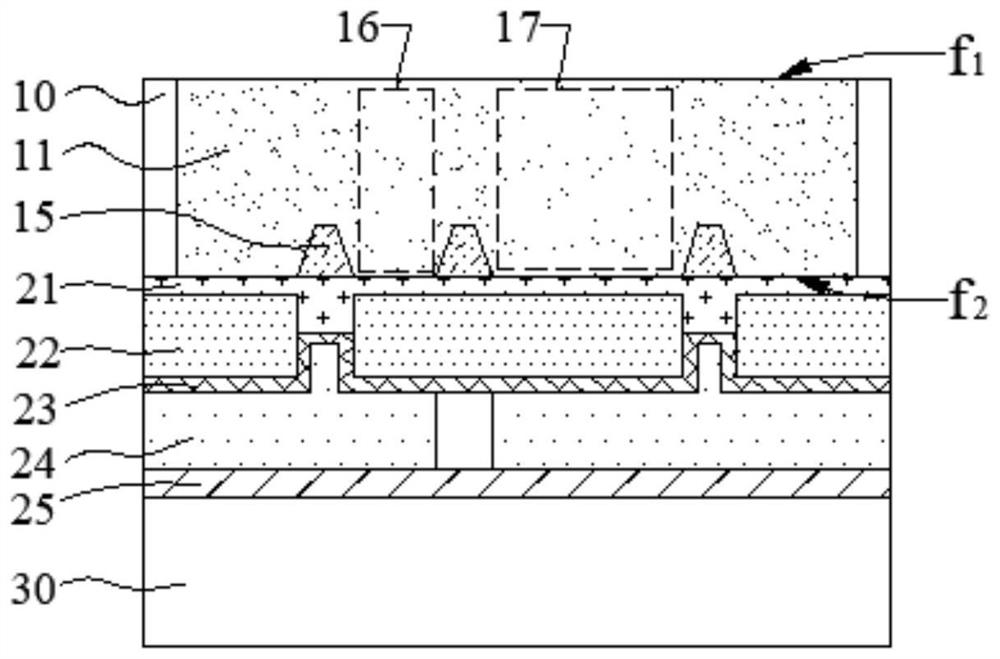

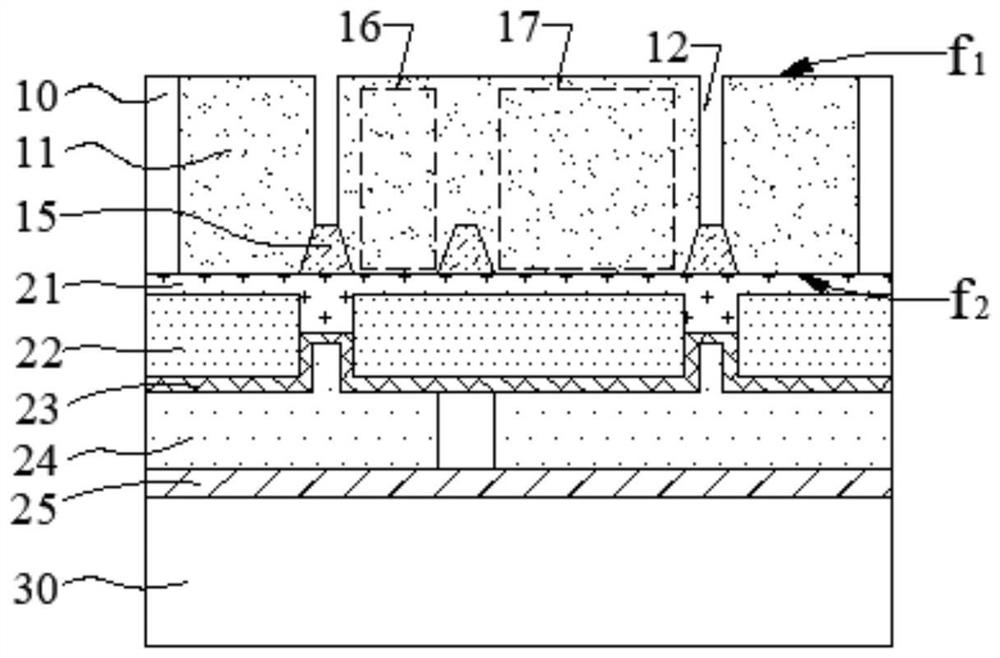

[0036]Embodiments of the present invention provide an image sensor and a method of making it. The invention is further described in detail below with reference to the accompanying drawings and specific embodiments. The advantages and features of the present invention will be more clear depending on below. It should be noted that the accompanying drawings use a very simplified form and use non-precision ratios, which is intended to be convenient, and clearly assisted in explaining the purposes of the embodiments of the present invention.

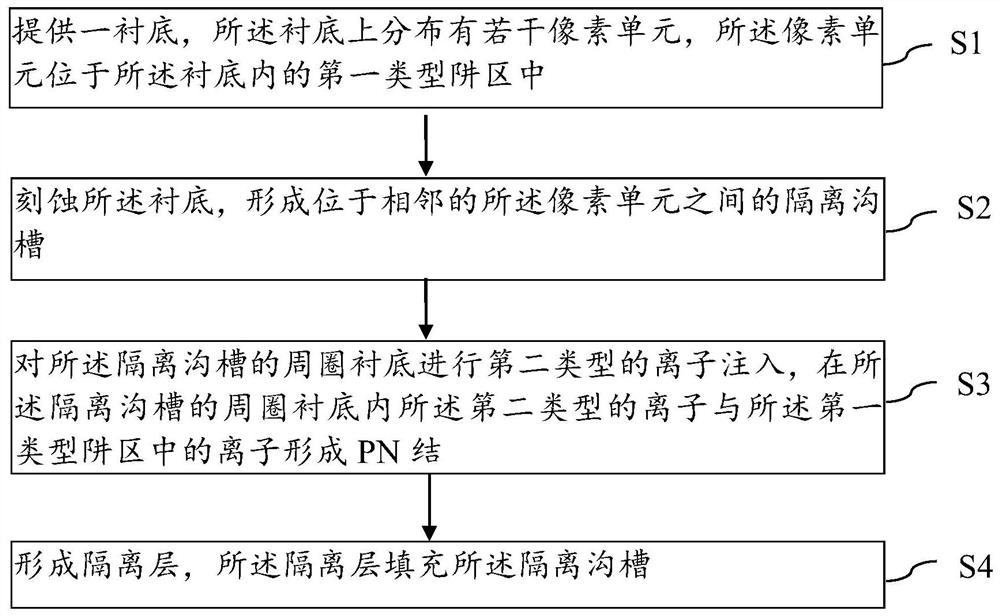

[0037]The embodiment of the present invention provides a method of making an image sensor, such asfigure 1 As shown, including:

[0038]A substrate is provided, and a plurality of pixel units are distributed on the substrate, and the pixel unit is located in a first type well region in the substrate;

[0039]The substrate is etched to form an isolation trench between adjacent pixel units;

[0040]The second type of ion implantation is performed on the peripher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com