A method for preparing a reduced graphene oxide coating on the surface of a magnesium alloy

A graphene layer, magnesium alloy technology, applied in the direction of coating, electrolytic coating, prosthesis, etc., to achieve the effect of safe experimental process, excellent photothermal effect, and large-scale industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

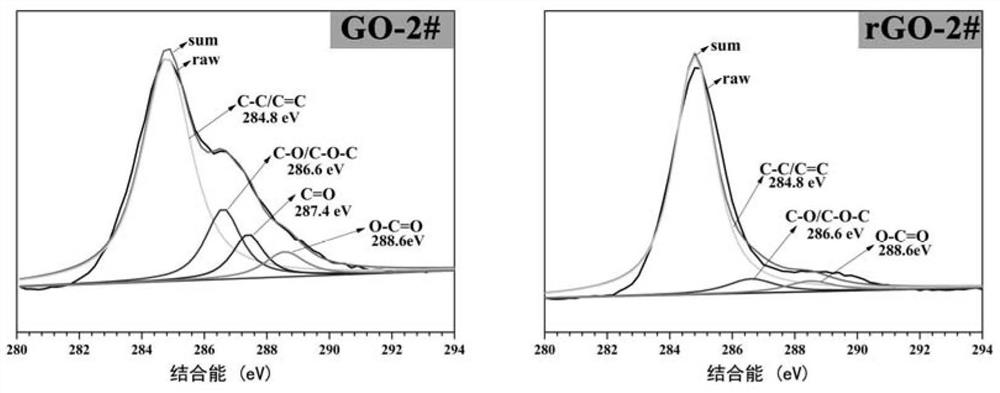

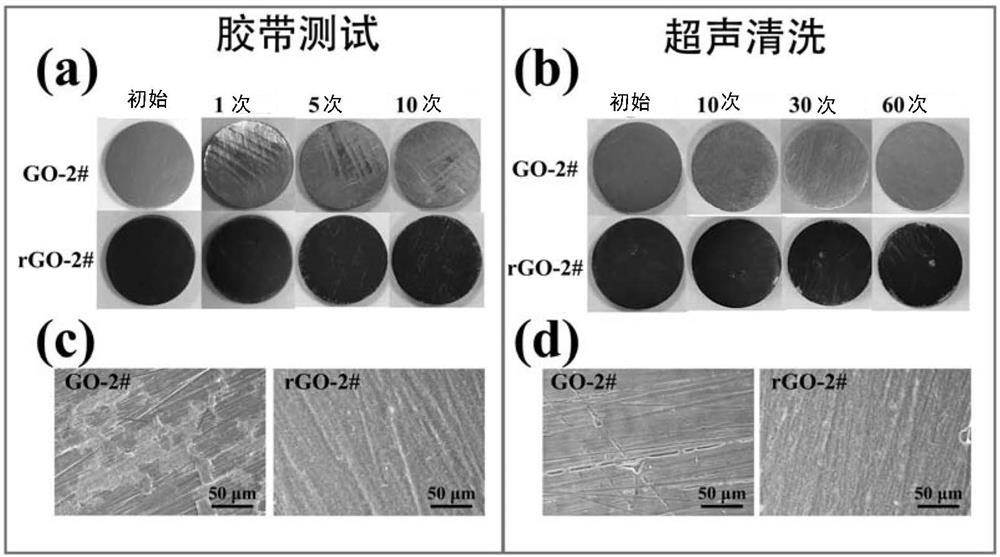

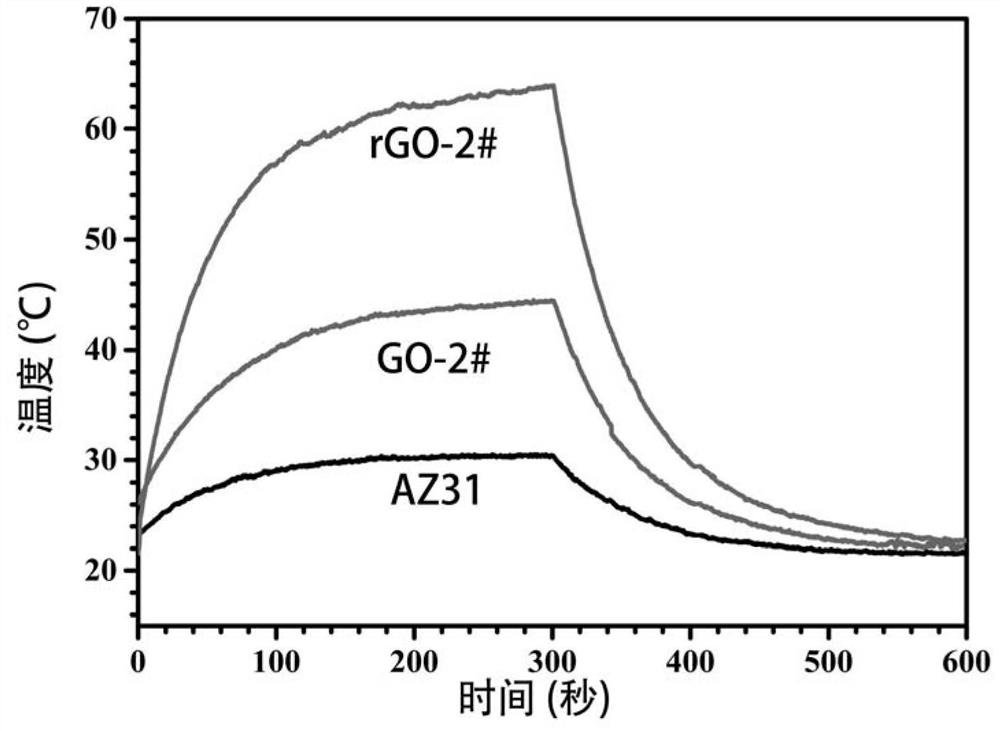

[0025] In the present disclosure, the synthesis method of the reduced graphene oxide coating having a strong binding force with the magnesium alloy substrate includes steps such as mechanical processing (or chemical corrosion, etc.), cleaning, electrophoretic deposition, drying, and immersion water reduction to obtain a surface Magnesium alloy material with reduced graphene oxide layer. The thickness of the reduced graphene oxide coating on the surface of the magnesium alloy material may be 5-15 μm. The oxygen content in the reduced graphene oxide coating can be 10-20 at%, and the Mg content in the reduced graphene oxide coating can be 5-10 at%. The following examples illustrate the preparation method of the reduced graphene oxide coating on the surface of the magnesium alloy material provided by the present invention.

[0026] Magnesium alloy pretreatment. During the machining process, the magnesium alloy was polished and smoothed with 600# and 1000# SiC sandpaper in sequen...

Embodiment 1

[0034] Use 600# and 1000# SiC sandpaper to remove the surface oxide layer of the AZ31 magnesium alloy sheet with a thickness of 2mm and a diameter of 10mm, and then use alcohol to ultrasonically clean it. Electrophoretic deposition is then carried out. The electrolyte is a 32 μg / mL graphene oxide solution (volume 250 ml), the solvent is absolute ethanol, and 50 mg of zinc acetate and 50 mg of zinc nitrate hexahydrate are added to the electrolyte. Electrodeposited at a voltage of 80V for 90s to obtain a graphene oxide coating, and the obtained sample was marked as GO-1#;

[0035] figure 1 (a) is a scanning electron microscope image of the surface morphology of the magnesium alloy obtained through the modification treatment in Example 1. It can be seen from the figure that graphene oxide is evenly covered on the surface of the magnesium alloy. figure 2 The XRD spectrum of the surface of the sample modified in Example 1 is given, and it can be seen that only the magnesium phas...

Embodiment 2

[0037]Use 600# and 1000# SiC sandpaper to remove the surface oxide layer of the AZ31 magnesium alloy sheet with a thickness of 2mm and a diameter of 10mm, and then use alcohol to ultrasonically clean it. Electrophoretic deposition is then carried out. The electrolyte is a 32 μg / mL graphene oxide solution (volume 250 ml), the solvent is absolute ethanol, and 50 mg of zinc acetate and 50 mg of zinc nitrate hexahydrate are added to the electrolyte. The graphene oxide coating was obtained by electrodeposition at a voltage of 80V for 120s, and the obtained sample was marked as GO-2#.

[0038] figure 1 (b) is a scanning electron microscope image of the surface morphology of the magnesium alloy obtained through the modification treatment in Example 2. It can be seen from the figure that graphene oxide is evenly covered on the surface of the magnesium alloy. figure 2 The XRD spectrum of the surface of the sample modified in Example 2 is given, and it can be seen that only the magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com