Production process of evodiamine and method for recycling solvent in production

A production process, the technology of evodiamine, applied in the field of organic synthesis, can solve the problems of high price, high toxicity and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

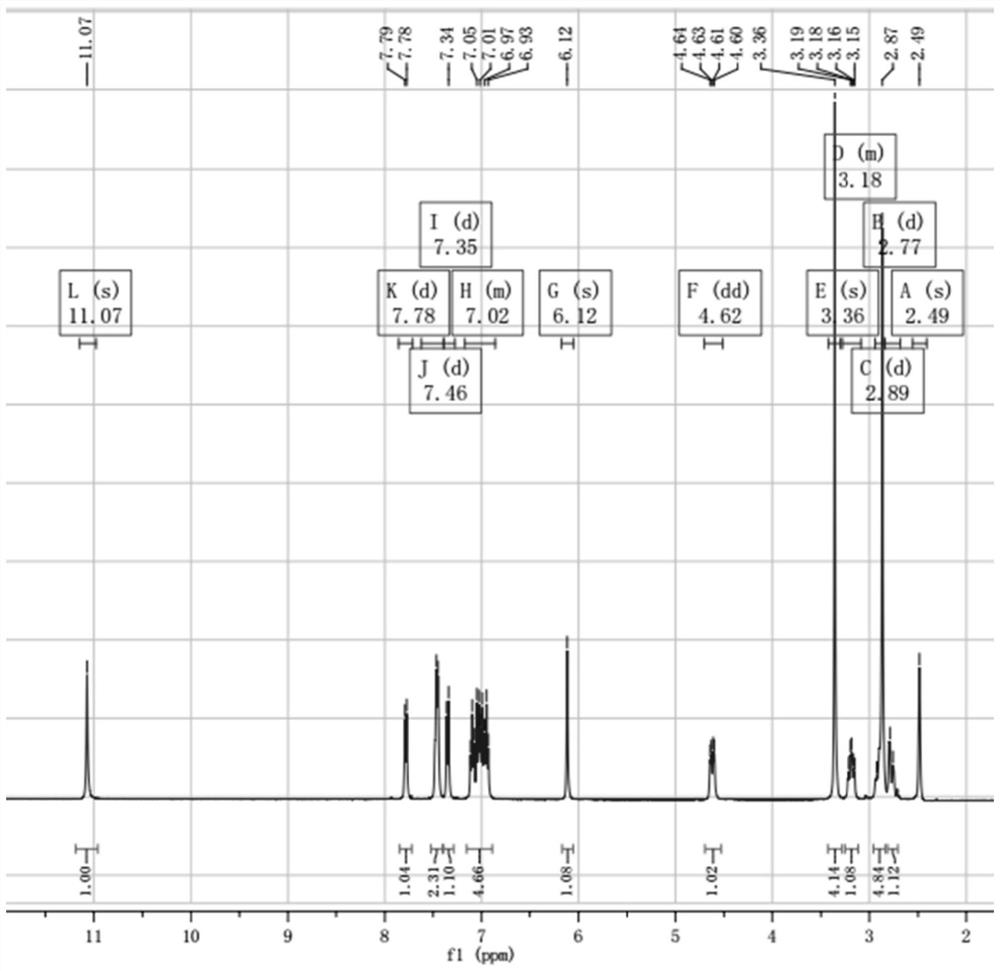

[0043] A kind of synthetic method of evodiamine

[0044] Step 1) tryptamine (160g, 1mol) was mixed with ethyl formate (960ml), and refluxed at 70°C for 12 hours. After the reaction, the temperature was lowered to 25°C, and ethyl formate was obtained by distillation under reduced pressure. The solid was washed with dichloromethane ( 500ml) was dissolved, washed with 50ml of water, the dichloromethane phase was dried over anhydrous sodium sulfate, filtered, and concentrated to obtain intermediate product A (172g, 0.91mol) with a purity of 98%. Ethyl formate was reserved for future use.

[0045] Step 2) Dissolve intermediate product A (172.1g, 0.91mol) in ethyl acetate (1.1L), cool down to 5°C, add trichlorophosphoric acid (238.7g, 1.56mol), react for 2 hours, raise to 25°C, After the reaction was complete, water (1.8 L) was added and the pH was adjusted to 10 with saturated potassium carbonate solution, and the aqueous phase was extracted several times with ethyl acetate until ...

Embodiment 2

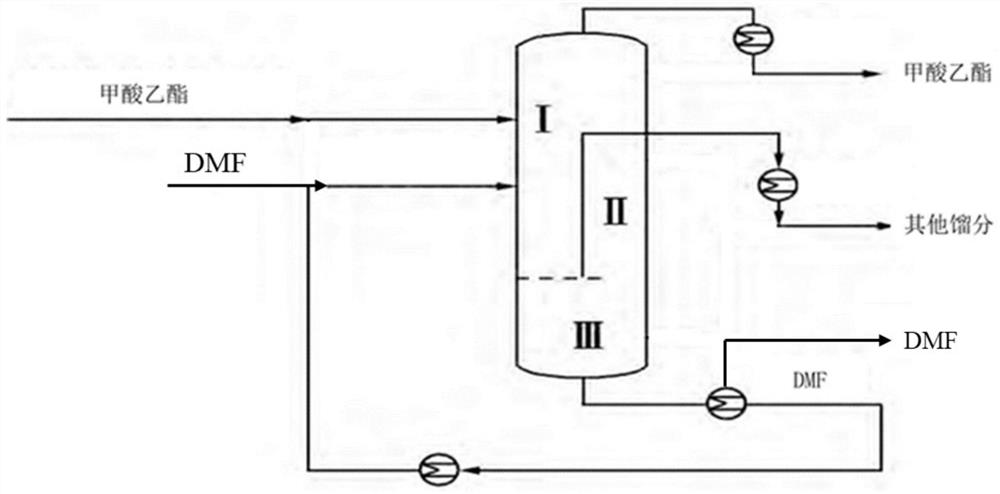

[0049] S1: multiple batches of ethyl formate obtained in Example 1 were combined, and DMF with 1.8 times the volume of ethyl formate was added to a dividing wall extractive distillation column for rectification;

[0050]S2: Collect the fraction at 53-58°C in the extraction and rectification section of area I to obtain ethyl formate; the fraction at 78-83°C in the side line rectification section of area II is used for waste liquid treatment; the rest is in the public stripping section of area III The liquid of the segment is DMF.

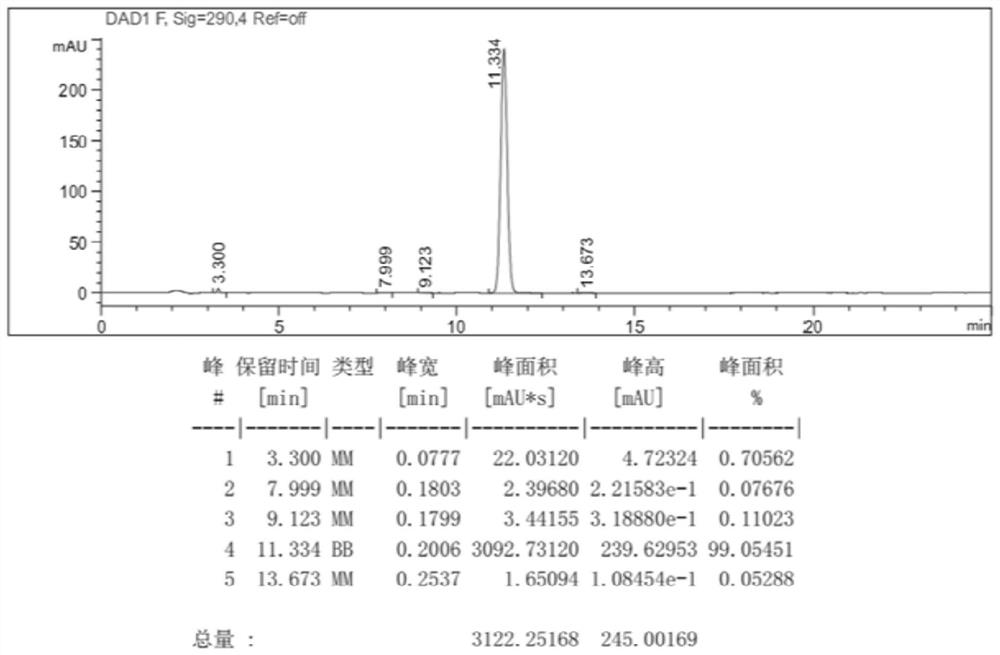

[0051] The purity of ethyl formate detected by HPLC was 99.7%, and the purity of DMF was 99.9%.

[0052] Example 3 - The difference with Example 1 is the use of recovered ethyl formate and DMF

[0053] A kind of synthetic method of evodiamine

[0054] Step 1) tryptamine (160g, 1mol) was mixed with ethyl formate (960ml) recovered in Example 2, and refluxed at 70°C for 12 hours. After the reaction, the temperature was lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com