A kind of method of recycling iso-terephthaloyl dichloride still residue

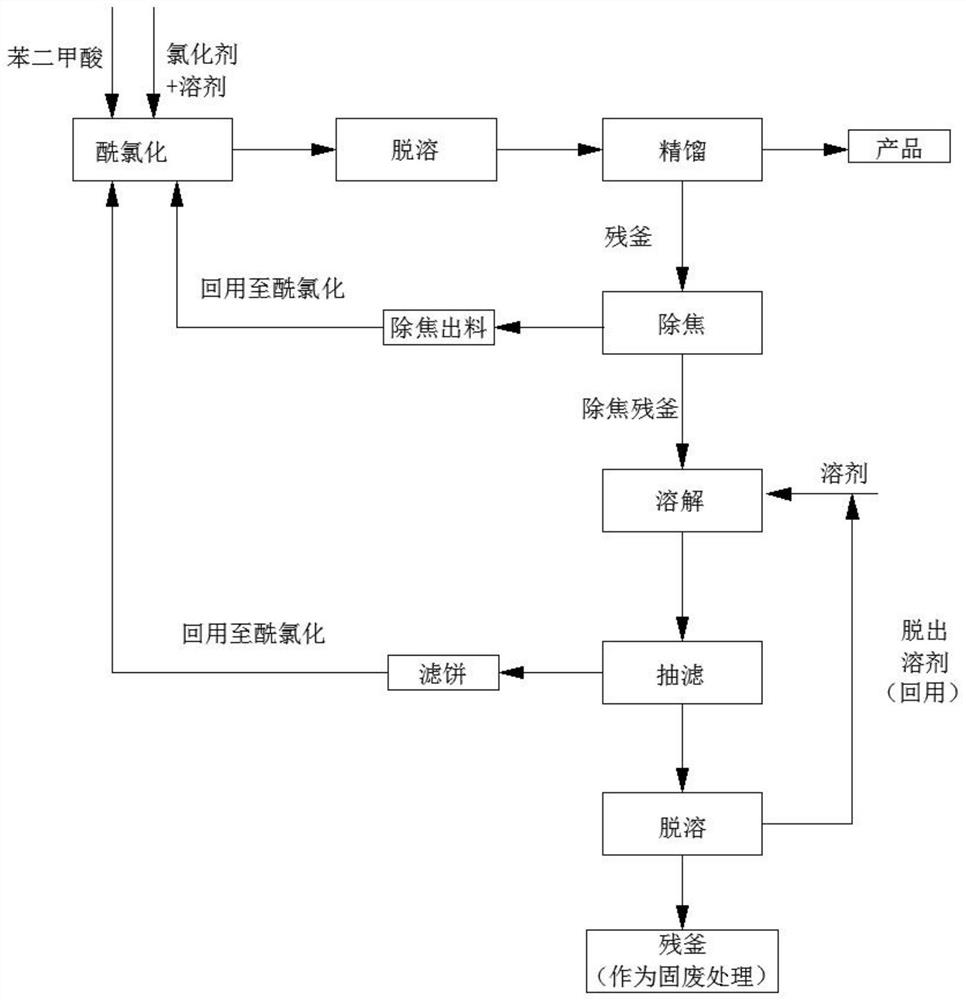

A technology of terephthaloyl chloride residue and resource utilization, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of waste of resources, environmental impact, low product purity and yield, etc. The process is simple, the effect of reducing the residual amount of the kettle and improving the product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

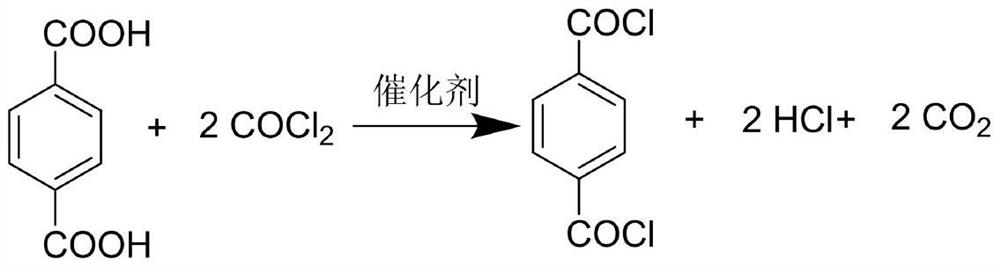

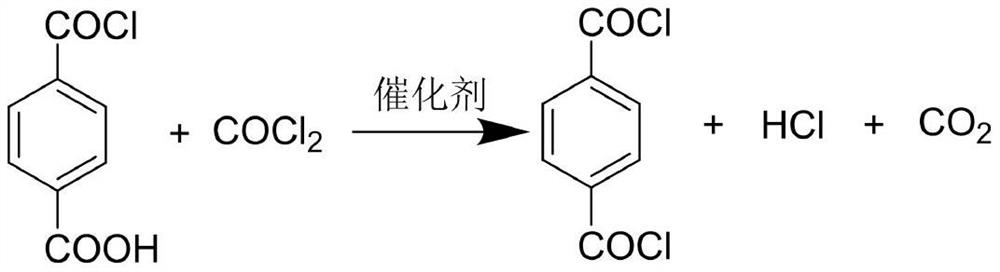

Method used

Image

Examples

Embodiment 1

[0051] Put 500g terephthaloyl chloride rectification still residue (containing 75% terephthaloyl chloride, 10% terephthalic acid monochloride, 10% tar, 5% terephthalic acid) into a 1000mL four-neck flask, under negative pressure Decoking is carried out at 1KPa; when the temperature / kettle temperature is 102°C / 104°C, the material is discharged until the kettle temperature is 160°C, and the decoking is completed; Add 152g of chlorobenzene and stir at 50°C, stir for 2 hours and then slightly cool down to 30°C and perform suction filtration to obtain 30g of wet-base filter cake (26g after drying), 198g of filtrate to remove the solvent chlorobenzene under negative pressure, and the residue of the precipitation kettle 52g, and 144g of recovered solvent; the residual amount of the distillation still is reduced by 89.6% after the treatment.

[0052] The decoking discharge and filter cake in the previous step are reused in the acid chloride synthesis process, and the product is obtain...

Embodiment 2

[0054] Put 500g isophthaloyl chloride rectifying still residue (containing 72% isophthaloyl chloride, 10% isophthalic acid monochloride, 12% tar, 6% isophthalic acid) into a 1000mL four-necked flask, under negative pressure Decoking is carried out at 2KPa; when the temperature / kettle temperature is 104°C / 106°C, the material is discharged until the kettle temperature is 170°C, and the coking is completed; 136.5g of chlorobenzene was added and stirred at 60°C. After stirring for 3 hours, the temperature was slightly lowered to 30°C and suction filtration was performed to obtain 35g of wet-base filter cake (30.5g after drying). The residue in the still is 61 g, and 130 g of the solvent is recovered; the residue in the distillation still is treated and the residue in the still is reduced by 87.8%.

[0055] The decoking discharge material and the filter cake in the previous step are reused in the acid chloride synthesis process, and the product is obtained after desolubilization an...

Embodiment 3

[0057] Put 500g terephthaloyl chloride rectification still residue (containing 60% terephthaloyl chloride, 13% terephthalic acid monochloride, 20% tar, 7% terephthalic acid) into a 1000mL four-neck flask, under negative pressure Decoking is carried out at 2KPa; when the temperature / kettle temperature is 110°C / 113°C, the material is discharged until the kettle temperature is 170°C, and the decoking is completed; Add 408g of thionyl chloride and stir at 30°C, and after stirring for 1 hour, perform suction filtration to obtain 42g of wet-based filter cake (35.5g after drying), 501g of filtrate to remove the solvent at normal pressure, and 100.5g of the remaining 100.5g of the precipitation tank to be recovered. Solvent 400g; after the rectification still residue is treated, the still residue is reduced by 79.9%.

[0058] The decoking discharge material and the filter cake in the previous step are reused in the acid chloride synthesis process, and the product is obtained after des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com