High-titanium blast furnace slag pervious concrete and using method thereof

A technology of permeable concrete and blast furnace slag, applied in the field of building materials, can solve the problems of development and application limitation, natural ecological environment damage, etc., and achieve the effects of reducing cost, reducing crushing process, and strong water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

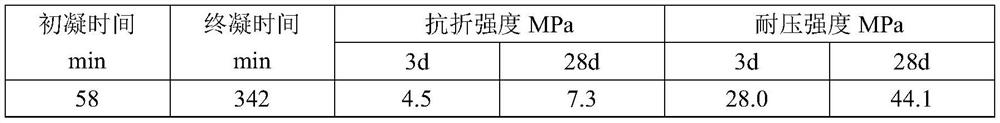

Embodiment 1

[0026] A preferred embodiment of the present invention provides a high-titanium blast furnace slag permeable concrete, which includes the following components in parts by mass: 1350 parts of high-titanium blast furnace slag particles, 420 parts of high-titanium blast furnace water-quenched slag, high-efficiency reducing 10 parts of aqua, containing SiO 2 12 parts of polymer emulsion with a content of 90 wt%, 14 parts of iron oxide red and 92 parts of water. Mix and stir all the raw materials evenly, spread and roll on the ground, and let it be cured naturally for 14 days.

[0027] Among them, the particles of high-titanium blast furnace slag are obtained by successively crushing, magnetically separating and sieving the surface dry shell formed by placing the high-titanium type blast furnace slag in a slag tank and naturally cooling it into 4-6 mm particles.

[0028] Among them, the water-quenched high-titanium blast furnace slag is formed by placing the high-titanium type bla...

Embodiment 2

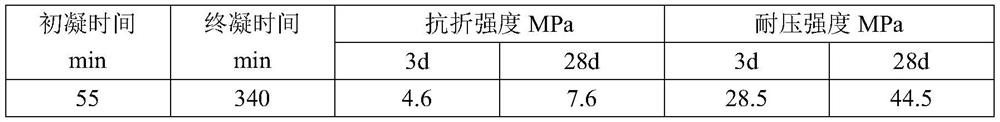

[0034] A preferred embodiment of the present invention provides a high-titanium blast furnace slag permeable concrete, which includes the following components in parts by mass: 1330 parts of high-titanium blast furnace slag particles, 410 parts of high-titanium blast furnace water-quenched slag, high-efficiency reducing 9 parts of water, containing SiO 2 12 parts of polymer emulsion with a content of 88 wt%, 13 parts of iron oxide red and 90 parts of water. Mix and stir all the raw materials evenly, spread and roll on the ground, and let it be cured naturally for 14 days.

[0035] Among them, the particles of high-titanium blast furnace slag are obtained by successively crushing, magnetically separating and sieving the surface dry shell formed by placing the high-titanium type blast furnace slag in a slag tank and naturally cooling it into 4-6 mm particles.

[0036] Among them, the water-quenched high-titanium blast furnace slag is formed by placing the high-titanium type bla...

Embodiment 3

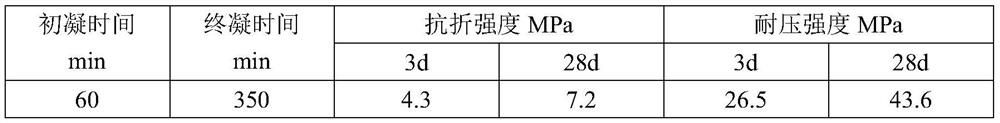

[0042] A preferred embodiment of the present invention provides a high-titanium blast furnace slag permeable concrete, which includes the following components in parts by mass: 1360 parts of high-titanium blast furnace slag particles, 440 parts of high-titanium blast furnace water-quenched slag, high-efficiency reducing 11 parts of aqua, containing SiO 2 13 parts of polymer emulsion with a content of 92 wt%, 15 parts of iron oxide red and 95 parts of water. Mix and stir all the raw materials evenly, spread and roll on the ground, and let it be cured naturally for 14 days.

[0043] Among them, the particles of high-titanium blast furnace slag are obtained by successively crushing, magnetically separating and sieving the surface dry shell formed by placing the high-titanium type blast furnace slag in a slag tank and naturally cooling it into 4-6 mm particles.

[0044] Among them, the water-quenched high-titanium blast furnace slag is formed by placing the high-titanium type bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com