Composite sandwich plate and preparation method and application thereof

A sandwich panel and surface layer technology, which is applied in the field of automobile interior decoration, can solve the problems of complex process flow, and achieve the effects of simple process flow, improved performance and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

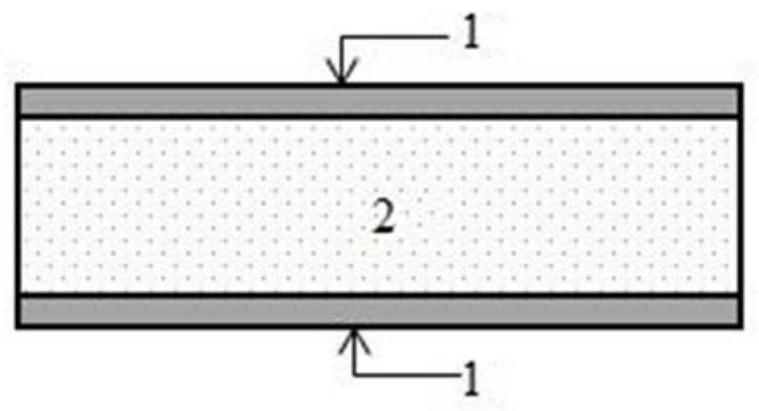

[0048] The specific embodiment part of the present invention provides a kind of preparation method of composite sandwich board, and described preparation method comprises the following steps:

[0049] (1) The glass fiber reinforced plastic board is heated, and the heating temperature of the upper and lower surfaces is different; the heated glass fiber reinforced plastic board, the polystyrene foam board and the heated glass fiber reinforced plastic board are stacked in order to obtain composite material;

[0050] (2) Compressing the combined material obtained in step (1) to obtain a composite sandwich panel.

Embodiment 1

[0053] The present embodiment provides a kind of preparation method of composite sandwich board, and described preparation method comprises the following steps:

[0054] (1) Put the PP glass fiber board into the oven to heat, the heating temperature of the upper surface is 280°C, the heating temperature of the lower surface is 300°C, heat for 100s, then take two heated PP glass fiber boards and a piece of polystyrene Foam boards are stacked in sequence in the order of heated PP fiberglass boards, polystyrene foam boards and heated PP fiberglass boards. When stacking, put the hot surface of the PP fiberglass boards close to the polystyrene foam Material, to get the composite material;

[0055] (2) Put the combined material obtained in step (1) into the mould, apply a pressure of 15MPa, keep for 60s, and obtain a composite sandwich panel; the thickness of the PP glass fiber board layer of the composite sandwich panel is 3mm, polystyrene foam board The layer thickness was 15 mm....

Embodiment 2

[0058] The present embodiment provides a kind of preparation method of composite sandwich board, and described preparation method comprises the following steps:

[0059] (1) Put the PP glass fiber board into the oven to heat, the heating temperature of the upper surface is 270°C, the heating temperature of the lower surface is 310°C, heat for 80s, then take two heated PP glass fiber boards and a piece of polystyrene Foam boards are stacked in sequence in the order of heated PP fiberglass boards, polystyrene foam boards and heated PP fiberglass boards. When stacking, put the hot surface of the PP fiberglass boards close to the polystyrene foam Material, to get the composite material;

[0060] (2) Put the combined material obtained in step (1) into the mould, apply a pressure of 14MPa, keep for 70s, and obtain a composite sandwich panel; the thickness of the PP glass fiber board layer of the composite sandwich panel is 4mm, polystyrene foam board The layer thickness was 17 mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com