Automatic pipe bending process of S-shaped pipe and automatic pipe bender of S-shaped pipe

A pipe bending machine and automatic technology, applied in the field of S-type automatic pipe bending machine, can solve the problems of slow production speed and unsuitable for large-scale production, etc., and achieve the effect of improving production speed, saving raw materials and increasing output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

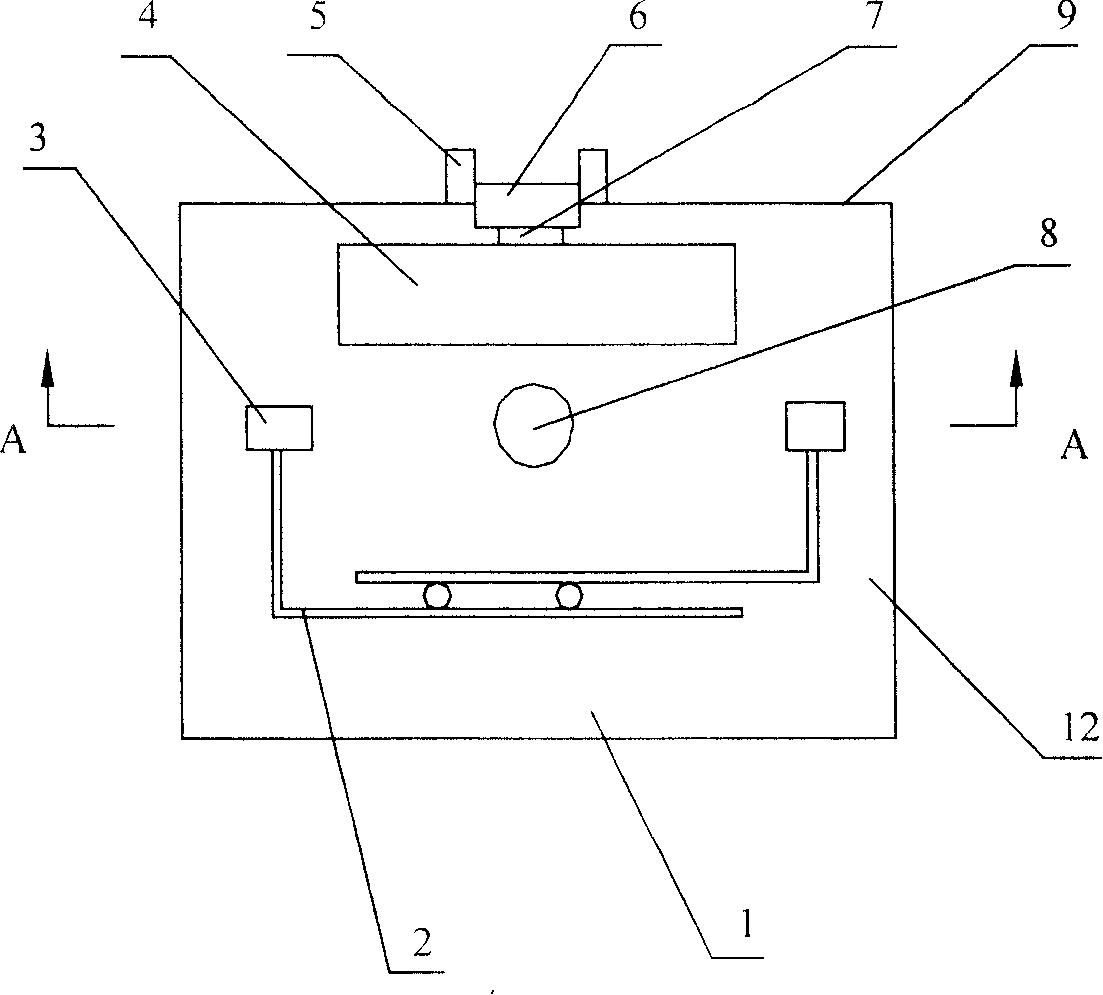

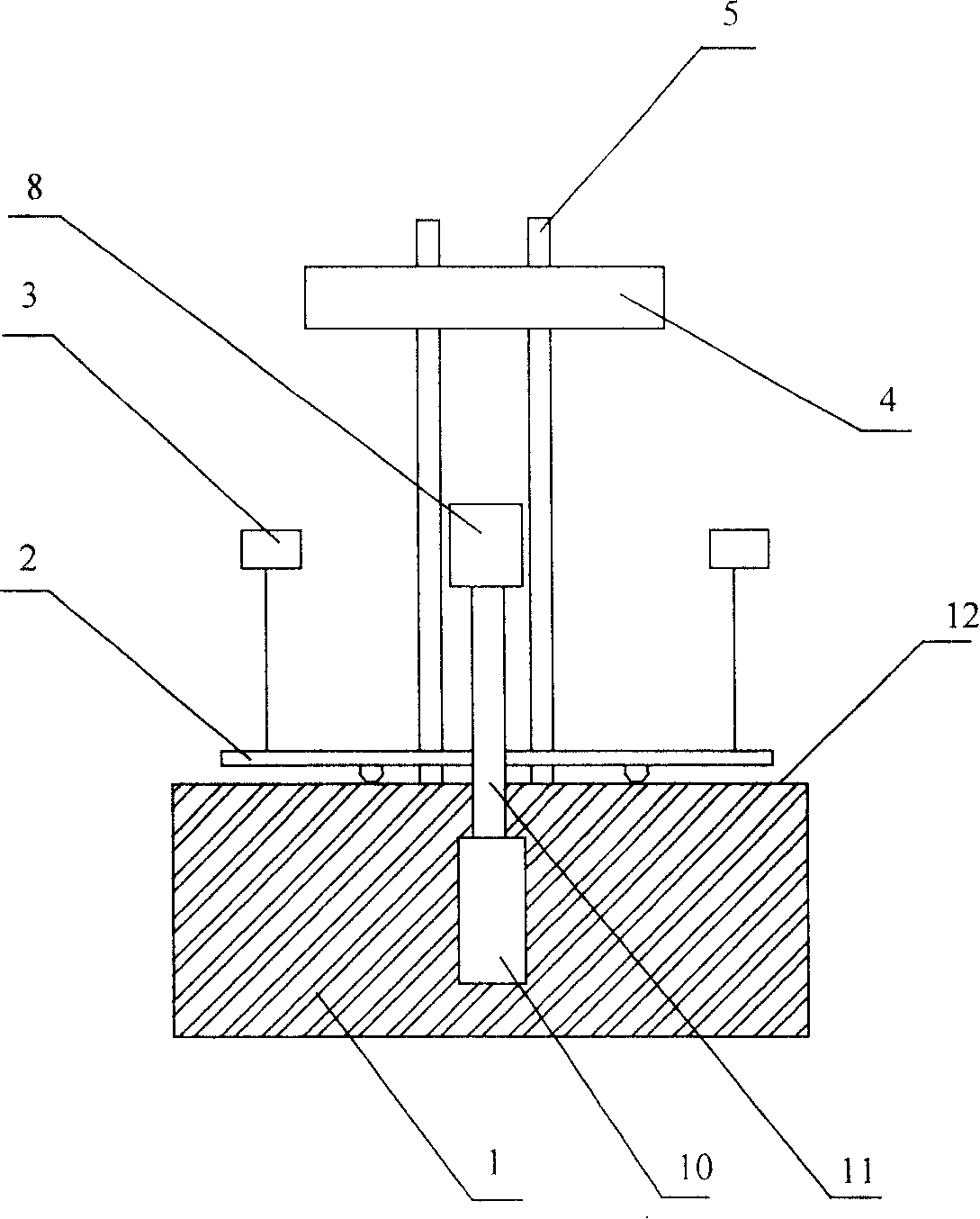

[0017] Specific embodiments of the present invention will be described in detail with reference to the above-mentioned drawings. figure 1 , figure 2 A kind of S-shaped pipe automatic pipe bending machine is provided in combination, which includes a working platform 1, and a lifting device 5 is arranged on the rear side 9 of the working platform 1, and the lifting device 5 can perform telescopic movement up and down. This lifting device 5 is provided with a horizontal movement mechanism 6, which is a forward cylinder with a piston rod 7. The oven 4 is connected with the piston rod 7, and the oven 4 is moved forward horizontally by the piston rod 7. A lifting mechanism 10 is arranged inside the center of the working platform 1, and the lifting mechanism 10 is a lifting cylinder with a piston rod 11, and the piston rod 11 can pass through the upper surface 12 of the working platform 1 and move upwards. The pipe bending die 8 is connected with the piston rod 11, and the pipe be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com