Forging process of magnesium-lithium alloy

A magnesium-lithium alloy and process technology, applied in the field of magnesium-lithium alloy forging process, can solve the problem of insufficient performance and high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

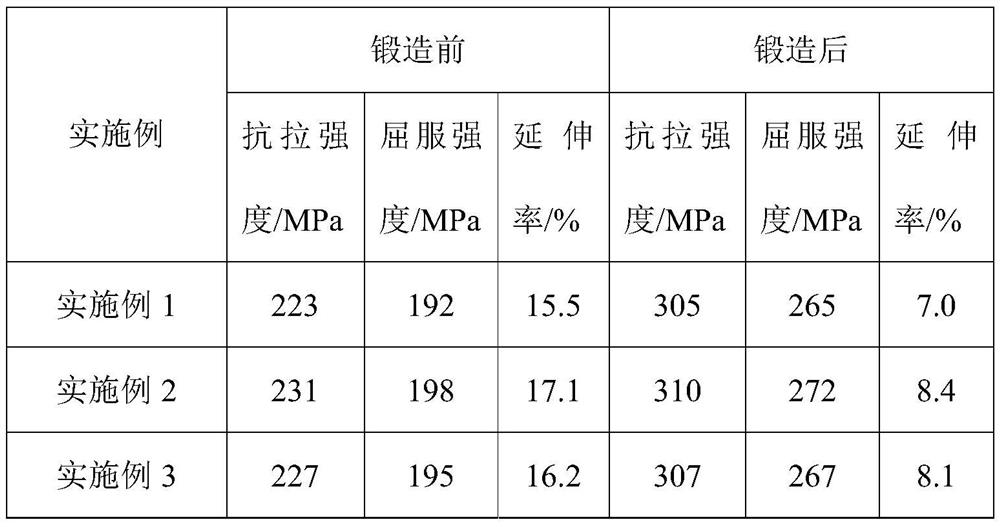

Embodiment 1

[0032] In this embodiment, the magnesium-lithium alloy ingot has a specification of Ф300 mm.

[0033] The forging process of the magnesium-lithium alloy in this embodiment mainly includes: blanking, heating, forging, air cooling and detection, specifically as follows:

[0034] Cutting: Use a sawing machine (model G4240) to saw the magnesium-lithium alloy ingot with a diameter of Ф300mm, and the size specification is Ф300×520mm;

[0035] Heating: the magnesium-lithium alloy ingot with a size of Ф300×520 mm is heated before forging through an electric furnace (model HY-S0101, HY-S0033). Install the furnace at a furnace temperature of ≤300°C, the magnesium-lithium alloy ingot is heated up with the furnace to the heating temperature: 300±10°C, and the holding time: 300min;

[0036] Forging: After the heat preservation is over, forging is carried out by a 2000T press (model HY-S0066). Divided into two fire forging, specifically:

[0037] 1 fire: first upsetting the Ф300×520mm bi...

Embodiment 2

[0044] In this embodiment, the magnesium-lithium alloy ingot has a specification of Ф260 mm.

[0045] The forging process of the magnesium-lithium alloy in this embodiment mainly includes: blanking, heating, forging, air cooling and detection, specifically as follows:

[0046] Cutting: Use a sawing machine (model G4240) to saw the magnesium-lithium alloy ingot with a diameter of Ф260mm, and the size specification is Ф260×520mm;

[0047] Heating: The magnesium-lithium alloy ingot with a size of Ф260×520 mm is heated before forging through an electric furnace (model HY-S0101, HY-S0033). Install the furnace at a furnace temperature of ≤300°C, the magnesium-lithium alloy ingot is heated up with the furnace to the heating temperature: 300±10°C, and the holding time: 260min;

[0048]Forging: After the heat preservation is over, forging is carried out by a 2000T press (model HY-S0066). Divided into two fire forging, specifically:

[0049] 1 fire: first upsetting the Ф260×520mm bil...

Embodiment 3

[0056] In this embodiment, the magnesium-lithium alloy ingot has a specification of Ф350 mm.

[0057] The forging process of the magnesium-lithium alloy in this embodiment mainly includes: blanking, heating, forging, air cooling and detection, specifically as follows:

[0058] Cutting: Use a sawing machine (model G4240) to saw the magnesium-lithium alloy ingot with a diameter of Ф350mm, and the size specification is Ф350×520mm;

[0059] Heating: The magnesium-lithium alloy ingot with a size of Ф350×520 mm is heated before forging through an electric furnace (model HY-S0101, HY-S0033). Install the furnace at a furnace temperature of ≤300°C, the magnesium-lithium alloy ingot is heated up with the furnace to the heating temperature: 300±10°C, and the holding time: 350min;

[0060] Forging: After the heat preservation is over, forging is carried out by a 2000T press (model HY-S0066). Divided into two fire forging, specifically:

[0061] 1 fire: first upsetting the Ф350×520mm bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com