A glass reshaping process

A molding process and glass technology, applied in glass molding, glass pressing, glass manufacturing equipment and other directions, can solve the problems of irregular glass shape, reduced product quality rate, uneven product shrinkage, etc., to achieve no change in structure, The effect of avoiding uneven heating and improving the product quality rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

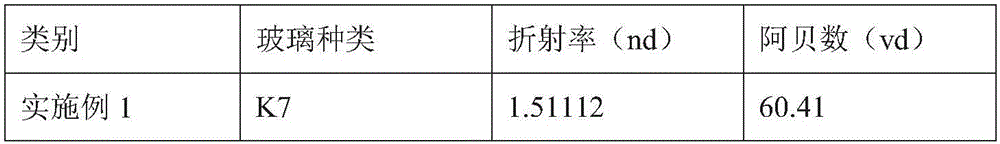

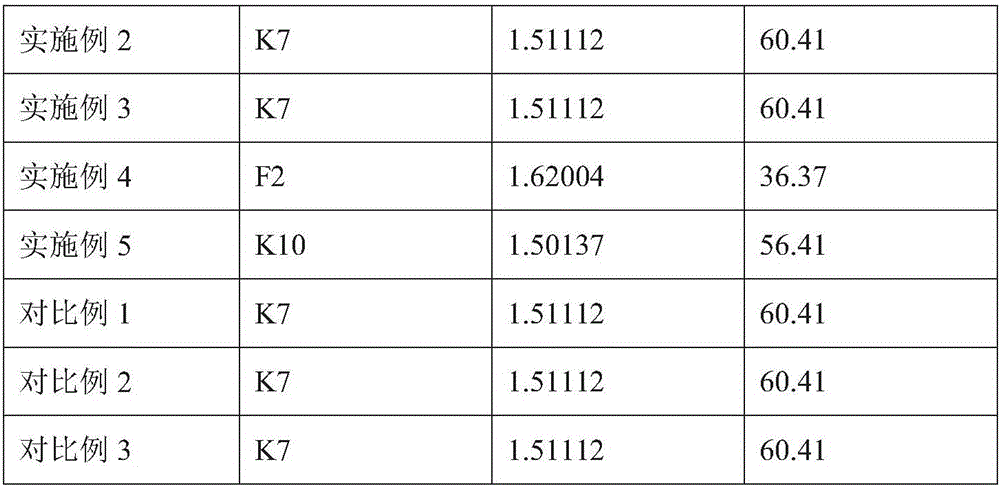

Embodiment 1

[0031] Embodiment 1 The technology of glass reshaping comprises the following steps:

[0032] (1) Preparation of coating: Take asbestos powder, silicone modified acrylate resin, methacryloxysilane, aluminosilicate and isopropanol respectively according to the proportioning ratio of 1:1.5:0.02:0.008:1. After the asbestos powder is ground, pass through a 600-mesh sieve, add methacryloxysilane and isopropanol to mix, put it in a high-speed disperser and disperse evenly for 8 minutes, add silicone modified acrylate resin and aluminosilicate to continue dispersing for 3 minutes , that is;

[0033] (2) Coating the surface of the glass blank with paint: use a sponge scraping tool or a brush to dip an appropriate amount of paint from top to bottom to coat with a coating thickness of 30μm, dry at 70°C for 30min, and then Dry at 100°C for 180min;

[0034] (3) Put the coated glass blank on the porcelain box, transport it into the heating zone in the softening furnace through the conve...

Embodiment 2

[0037] Embodiment 2 The technology of glass reshaping comprises the following steps:

[0038] (1) Preparation of coating: Take asbestos powder, silicone modified acrylate resin, methacryloyloxysilane, aluminosilicate and isopropanol respectively according to the proportioning ratio of 1:2:0.04:0.01:1.5. After the asbestos powder is ground, pass through a 600-mesh sieve, add methacryloxysilane and isopropanol to mix, put it in a high-speed disperser and disperse evenly for 8 minutes, add silicone modified acrylate resin and aluminosilicate to continue dispersing for 3 minutes , that is;

[0039] (2) Coating the surface of the glass blank with paint: use a sponge scraping tool or a brush to dip an appropriate amount of paint from top to bottom to coat with a coating thickness of 30μm, dry at 70°C for 30min, and then Dry at 100°C for 180mmin;

[0040](3) Put the coated glass blank on the porcelain box, transport it into the heating zone in the softening furnace through the con...

Embodiment 3

[0043] Embodiment 3 The technology of glass reshaping comprises the following steps:

[0044] (1) Preparation of coating: Take asbestos powder, silicone modified acrylate resin, methacryloyloxysilane, aluminosilicate and isopropanol respectively according to the proportioning ratio of 1:1.5:0.01:0.005:1. After the asbestos powder is ground, pass through a 600-mesh sieve, add methacryloxysilane and isopropanol to mix, put it in a high-speed disperser and disperse evenly for 8 minutes, add silicone modified acrylate resin and aluminosilicate to continue dispersing for 3 minutes , that is;

[0045] (2) Coating the surface of the glass blank with paint: use a sponge scraping tool or a brush to dip an appropriate amount of paint from top to bottom to coat with a coating thickness of 30μm, dry at 70°C for 30min, and then Dry at 100°C for 180mmin;

[0046] (3) Put the coated glass blank on the porcelain box, transport it into the heating zone in the softening furnace through the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com