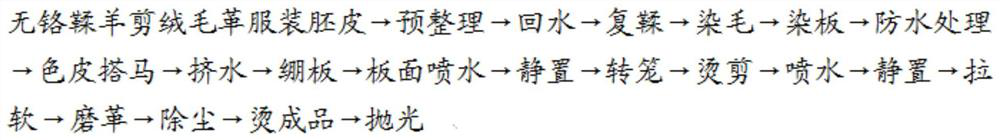

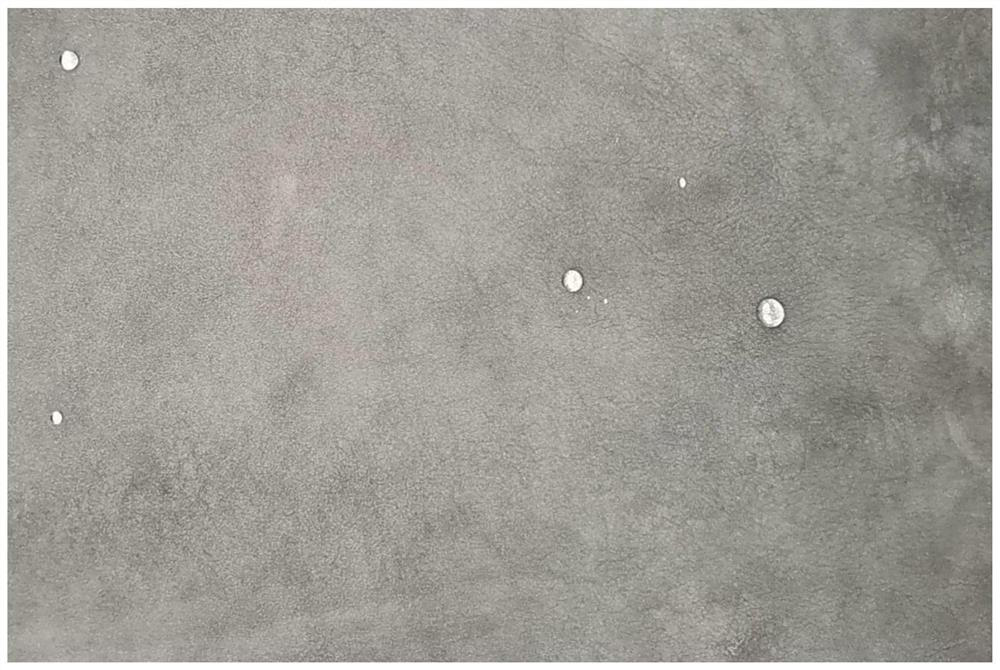

Waterproof agent and wool dyeing agent for chrome-free tanned Chenille leather and environment-friendly dyeing process of chrome-free tanned Chenille leather

A technology for tanning leather and water repellent, applied in the field of leather processing, can solve the problems of reduced color fullness of the board surface, high production energy consumption, and inability to guarantee safety, so as to solve the problem of poor product performance, improve waterproof performance, and waterproof great effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

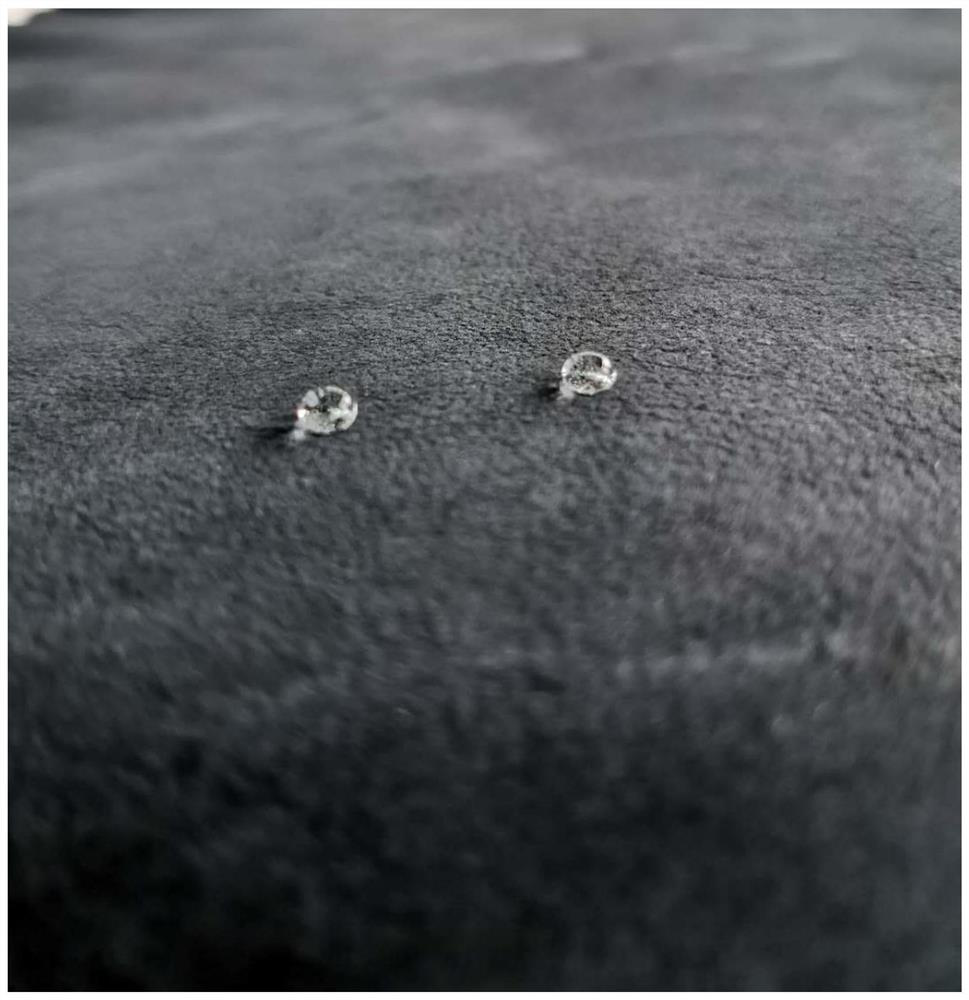

[0187] 1 Pre-finishing: scalding, shearing, brushing the wool surface with alcohol water, scalding and shearing twice, the scalding temperature is 160-170°C, and the wool is required to be loose, smooth and free from sticking hair;

[0188] 2 Backwater: equipment drum, 1000% water, temperature 40°C, add 1% ammonia water, 2% high-efficiency environmental protection degreasing agent VLC-3, rotate for 60 minutes, add 1% Levatan L, rotate for 120 minutes , drain and rinse with cold water once;

[0189] 3 Retanning: equipment drum, 1000% water, temperature 40°C, pre-fatliquor treatment, add 1% sulfonated oil TIS, 2% synthetic fatliquor GLH, rotate for 30 minutes, add 1% formic acid, rotate For 20 minutes, adjust the pH of the bath solution to 3.8-4.0, add fatty aldehyde DC (N) 2%, rotate for 30 minutes, add cationic synthetic tanned CAT 4%, rotate for 90 minutes, add 2.5% sodium formate, rotate for 120 minutes, adjust pH4. 0±, drain and wash twice in cold water;

[0190] 4. Wool ...

Embodiment 2

[0214] 1 Pre-finishing: scalding, shearing, brushing the wool surface with alcohol water, scalding and shearing twice, the scalding temperature is 160-170°C, and the wool is required to be loose, smooth and free from sticking hair;

[0215] 2 Backwater: equipment drum, 1000% water, temperature 40°C, add 1% ammonia water, 2% high-efficiency environmental protection degreasing agent VLC-3, rotate for 60 minutes, add 1% IPF, rotate for 120 minutes, drain, Rinse once in cold water;

[0216] 3 Retanning: equipment drum, 1000% water, temperature 40°C, first do pre-fatliquor treatment, add 1% sulfonated oil TIS, 2% fatliquor CFS, rotate for 30 minutes, add 1% formic acid, rotate for 20 minutes Minutes, adjust the bath liquid pH3.8~4.0, add fatty aldehyde PF 2%, turn for 30 minutes, add cationic synthetic tanning CAT 4%, turn for 90 minutes, add sodium formate 2.5%, turn for 120 minutes, adjust pH4.0±, drain , wash twice in cold water;

[0217] 4. Wool dyeing: equipment drum, 1000% ...

Embodiment 3

[0241] 1 Pre-finishing: scalding, shearing, brushing the wool surface with alcohol water, scalding and shearing twice, the scalding temperature is 160-170°C, and the wool is required to be loose, smooth and free from sticking hair;

[0242] 2 Backwater: equipment drum, 1000% water, temperature 40°C, add 1% ammonia water, 2% high-efficiency environmental protection degreasing agent VLC-3, rotate for 60 minutes, add 1% PMB, rotate for 120 minutes, drain, Rinse once in cold water;

[0243] 3 Retanning: equipment drum, 1000% water, temperature 40°C, first do pre-fatliquor treatment, add 1% sulfonated oil ELS, 2% synthetic fatliquor WWL, rotate for 30 minutes, add 1% formic acid, rotate For 20 minutes, adjust the pH of the bath solution to 3.8-4.0, add fatty aldehyde PAL 2%, rotate for 30 minutes, add cationic synthetic tanned CAT 4%, rotate for 90 minutes, add 2.5% sodium formate, rotate for 120 minutes, adjust the pH to 4.0±, Drain and wash twice in cold water;

[0244] 4. Wool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com