Concrete maintaining agent

A concrete curing agent and solution mixing technology, applied in the field of concrete curing agent, can solve the problems of limited popularization and application, low water retention rate, easy pollution of the environment, etc., and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

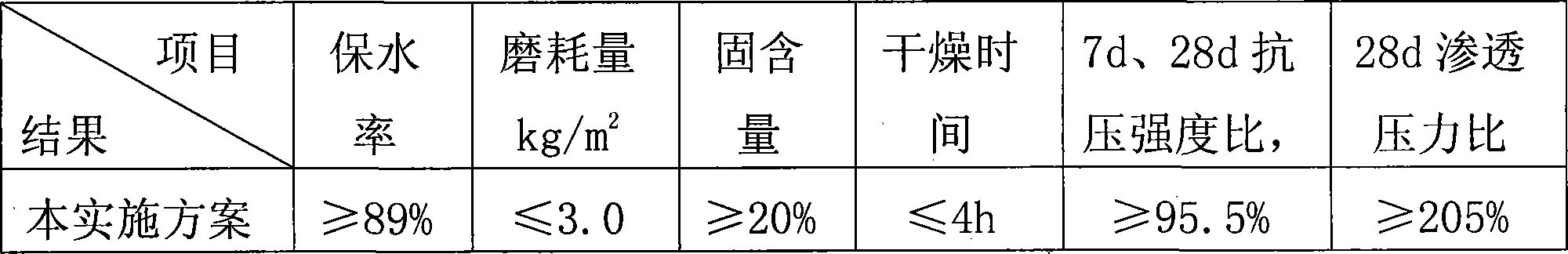

Embodiment 1

[0039] Embodiment 1, a kind of concrete curing agent, the weight proportion (by weight) of each component is: the styrene-acrylic emulsion 35g that the weight percent concentration is 50%, the acrylamide solution 45g that the weight percent concentration is 10%, the weight percent concentration 12g of 30% sodium silicate solution, 8g of organosilane solution with a concentration of 35% by weight, the styrene-acrylic emulsion uses ULTEX-601 styrene-acrylic emulsion produced by Shanyang Chemical Co., Ltd., and the acrylamide solution uses Xinxiang Xiaosheng Chemical Co., Ltd. The acrylamide solution and sodium silicate solution produced by the company use the sodium silicate solution produced by Xinghe Chemical Factory in Yongqing County, and the organic silane solution adopts commercially available products. Pour the styrene-acrylic emulsion into the acrylamide solution and add sodium silicate solution and organic silane solution are mixed at low speed to form a concrete curing ...

Embodiment 2

[0053] Embodiment 2, a kind of concrete curing agent, the weight proportion (by weight) of each component is: the styrene-acrylic emulsion 65g that the weight percent concentration is 35%, the acrylamide solution 20g that the weight percent concentration is 2%, the weight percent concentration 10g of 40% sodium silicate solution, 5g of organosilane solution with a concentration of 40% by weight, S-01 styrene-acrylic emulsion produced by Nantong Shengda Chemical Co., Ltd. for the styrene-acrylic emulsion, and Xinxiang Xinchang Chemical Co., Ltd. for the acrylamide solution The acrylamide solution produced by the company, the sodium silicate solution uses the sodium silicate solution produced by Jiangsu Kangxiang Group Co., Ltd., and the organic silane solution adopts commercially available products. The styrene-acrylic emulsion is poured into the acrylamide solution, and the sodium silicate solution is added. Stir the organic silane solution at a low speed to form a concrete cur...

Embodiment 3

[0067] Embodiment 3, a kind of concrete curing agent, the weight proportion (by weight) of each component is: the styrene-acrylic emulsion 50g that the weight percent concentration is 40%, the acrylamide solution 40g that the weight percent concentration is 6%, the weight percent concentration 5g of 35% sodium silicate solution, 5g of organosilane solution with a concentration of 38% by weight, the styrene-acrylic emulsion uses the H-100 styrene-acrylic emulsion produced by Ma'anshan Jiuhe Chemical Technology Co., Ltd., and the acrylamide solution uses Xinxiang Chemical Industry Co., Ltd. Co., Ltd. production of acrylamide solution, sodium silicate solution using the sodium silicate solution produced by Jiangsu Kangxiang Group Co., Ltd., organic silane solution using commercially available products, pour the styrene-acrylic emulsion into the acrylamide solution, add sodium silicate solution , Stir the organic silane solution at a low speed to form a concrete curing agent.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com