Smalt for PVC (Poly Vinyl Chloride) plastic processing

A polyvinyl chloride and plastic technology, applied in the field of color sand for pigment preparations, can solve the problems of large investment, affecting the aesthetic effect, dark spots of sulfide, etc., and achieve the effect of keeping the environment clean and adding process conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] formula:

[0043] Carrier 45%

[0044] Auxiliary 5%

[0045] Pigment 50%

[0046] in:

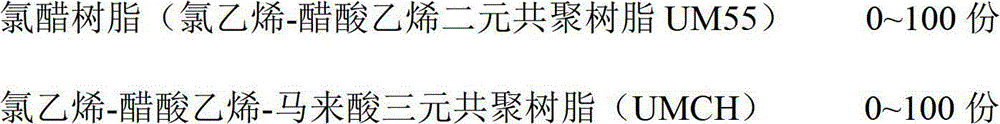

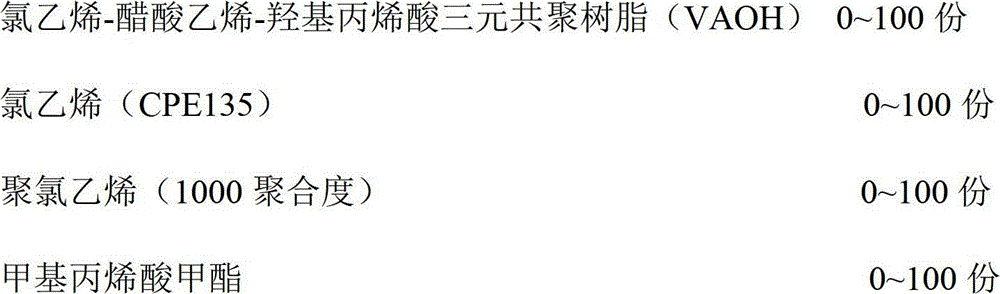

[0047] The carrier is composed of the following components in parts by weight:

[0048]

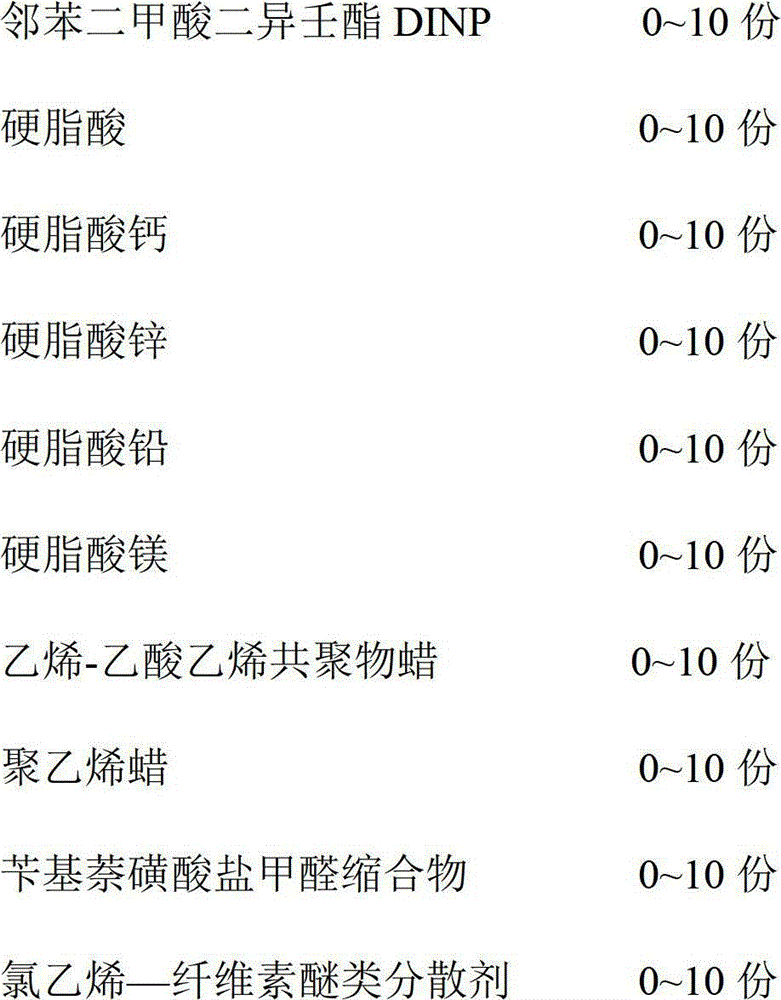

[0049] Auxiliary is made up of the component of following parts by weight:

[0050]

[0051] The pigment is phthalocyanine green.

[0052] The components are mixed, stirred and dispersed to obtain the product.

[0053] The industry standard QB 1648-92 of polyethylene coloring masterbatch was used for testing, and the results are as follows:

[0054] serial number

[0055] 3

Embodiment 2

[0057] formula:

[0058] Carrier 20%

[0059] Auxiliary 10%

[0060] Pigment 70%

[0061] in:

[0062] The carrier is composed of the following components in parts by weight:

[0063]

[0064] Auxiliary is made up of the component of following parts by weight:

[0065]

[0066]

[0067] The pigment is iron red.

[0068] The components are mixed, stirred and dispersed to obtain the product.

[0069]The industry standard QB 1648-92 of polyethylene coloring masterbatch was used for testing, and the results are as follows:

[0070] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com