Manufacturing method of manganese-zinc ferrite large magnetic core

A technology of manganese-zinc ferrite and a manufacturing method, which is applied in the field of magnetic core manufacturing, can solve the problems of poor coercivity, decreased production efficiency, and inability to guarantee the structure, and achieves enhanced magnetic permeability, improved service life, and improved structure. tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

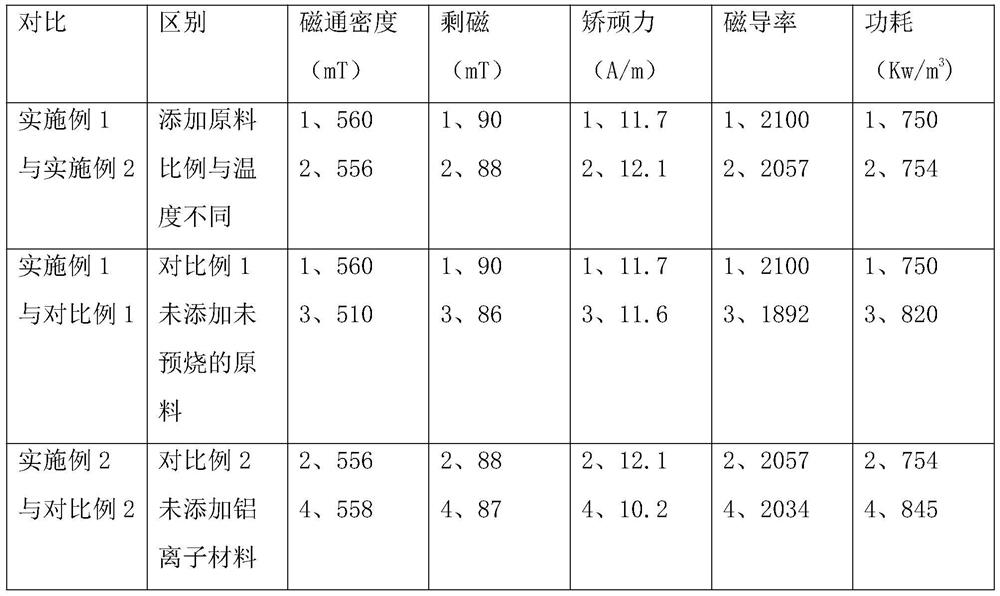

Embodiment 1

[0038] An embodiment of the present invention provides a method for manufacturing a large MnZn ferrite core, comprising the following steps:

[0039] S1. Mixing of selected materials: select raw materials of suitable purity, raw materials include ferric oxide, trimanganese tetroxide, zinc oxide, and then mix according to the proportion by weighing, and its molar percentage is; ferric oxide: 50 %, trimanganese tetroxide 40%, zinc oxide 10%, these proportions, the magnetic core permeability and magnetic flux density at the manufacturing place are relatively high;

[0040] S2. Perform pelletizing: finely grind the mixed raw materials, then add pure water for stirring, and make 2-10mm spheres through a pelletizing machine;

[0041] S3. Carry out pre-firing: place the finished sphere on the frame, and pre-fire it by placing it in a rotary kiln, and the pre-burning temperature is 850°C, which is convenient for transforming its internal structure;

[0042] S4. Vibration and grinding...

Embodiment 2

[0054] An embodiment of the present invention provides a method for manufacturing a large MnZn ferrite core, comprising the following steps:

[0055] S1. Mixing of selected materials: select raw materials of suitable purity, raw materials include ferric oxide, trimanganese tetroxide, zinc oxide, and then mix according to the proportion by weighing, and its molar percentage is; ferric oxide: 58 %, trimanganese tetroxide 30%, zinc oxide 12%, these proportions, the magnetic core permeability and magnetic flux density at the manufacturing place are relatively high;

[0056] S2. Perform pelletizing: finely grind the mixed raw materials, then add pure water for stirring, and make 2-10mm spheres through a pelletizing machine;

[0057] S3. Carry out pre-firing: place the finished sphere on the frame, and pre-fire it by placing it in a rotary kiln, and the pre-burning temperature is 930°C, which is convenient for transforming its internal structure;

[0058] S4. Vibration and grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com