Passing rate related strain induced metal high-cycle fatigue strengthening method

A strain-induced, high-cycle fatigue technology, applied in the fields of materials and machinery, can solve the problems of lack of strain rate research and introduction, and achieve the effect of convenient application and promotion, strong applicability, and hindering expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

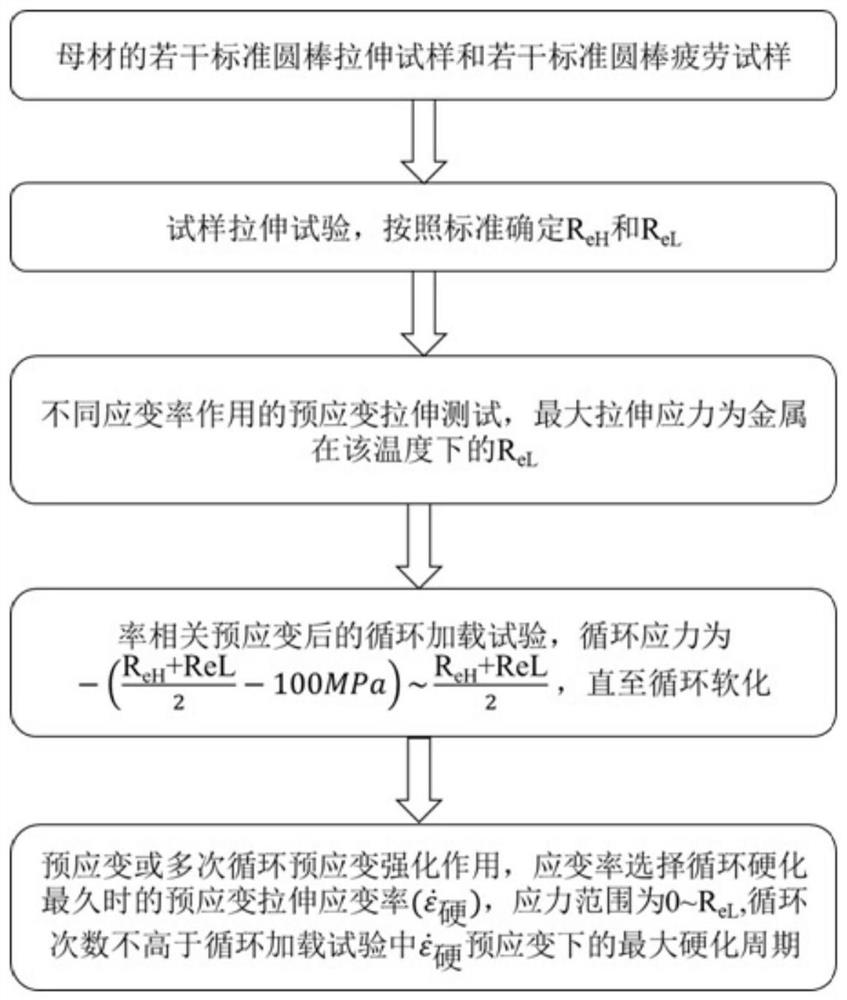

[0037] A method for inducing metal high-cycle fatigue strengthening through rate-dependent strain, a specific embodiment of the present invention is:

[0038] (1) Cut the 50# steel ingot after hot rolling, and prepare some standard round bar tensile samples and some standard round bar fatigue samples according to standard GB / T 228.1-2010 and GB / T 3075-2008;

[0039] (2) Simulate the long-term service environment of metal products or components through a temperature control box, and perform tensile tests on several tensile samples in this temperature environment according to the standard GB / T 228.1-2010, and determine the upper yield strength of the metal material ( R eH ) is 385MPa, the lower yield strength (R eL ) is 285MPa;

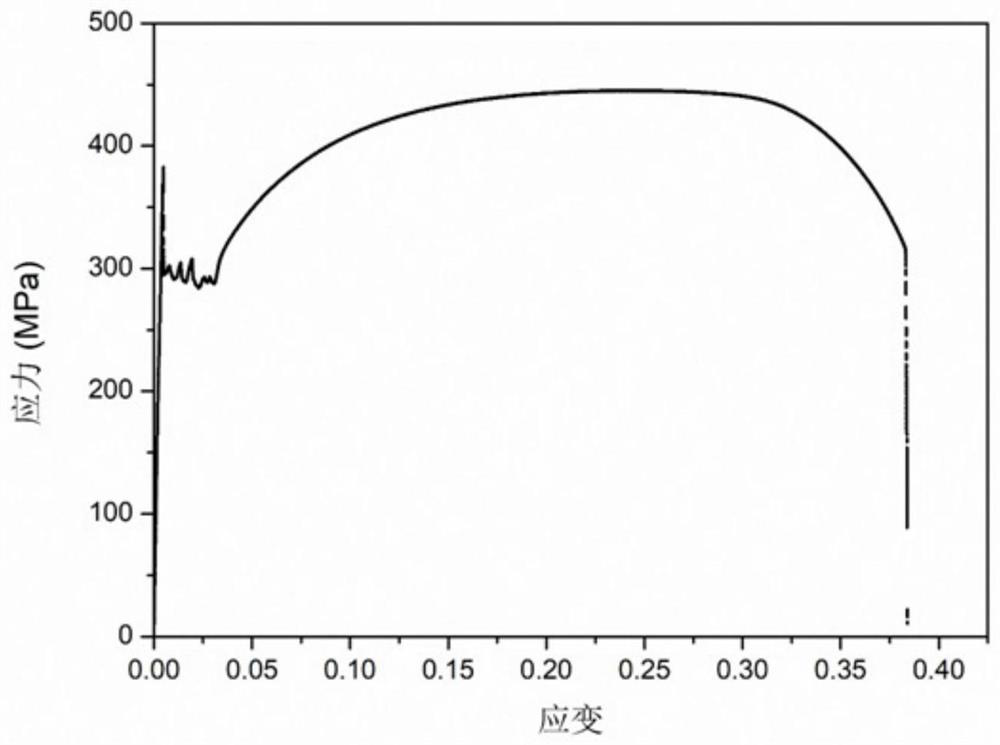

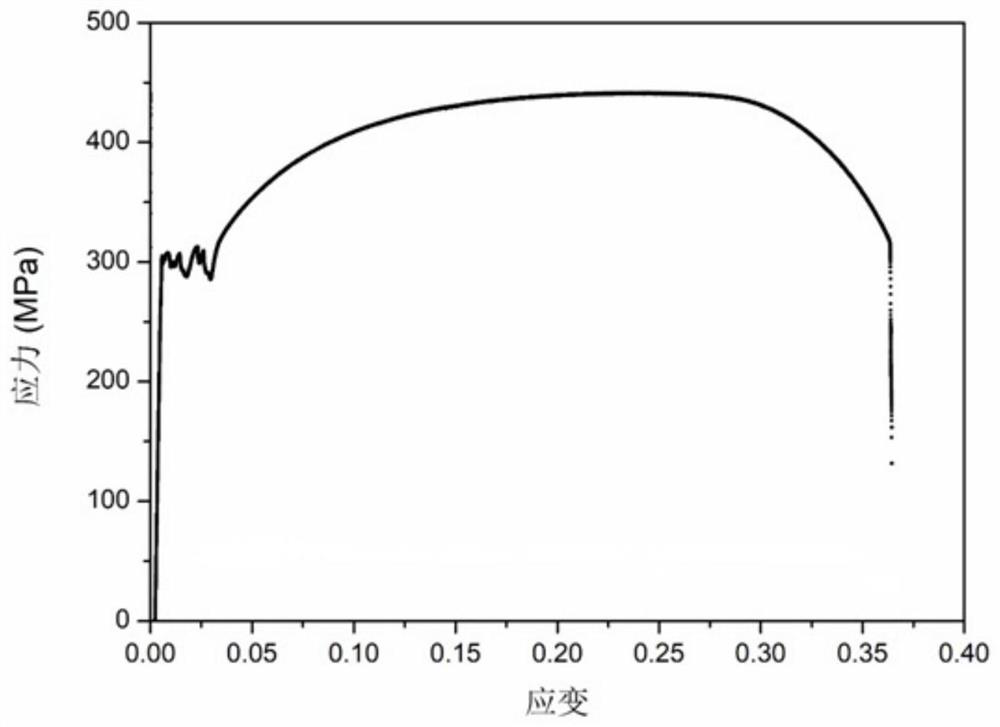

[0040] (3) A number of fatigue samples of the same material were subjected to pre-strain tensile tests under the temperature environment, and the tensile strain rates were 10 -5 the s -1 、10 -4 the s -1 、10 -3 the s -1 、10 -1 the s -1 , the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com