Method for refining carbide in large-size GH4738 cast ingot

A carbide and large-size technology, which is applied in the direction of improving process efficiency and energy efficiency, to achieve the effects of refining carbide size, reducing cooling time, and reducing growth time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

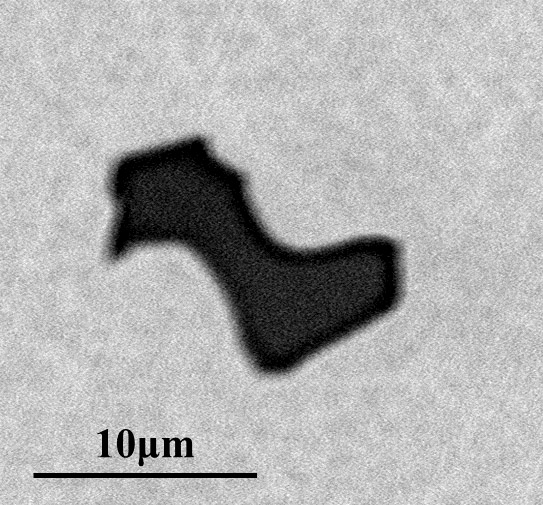

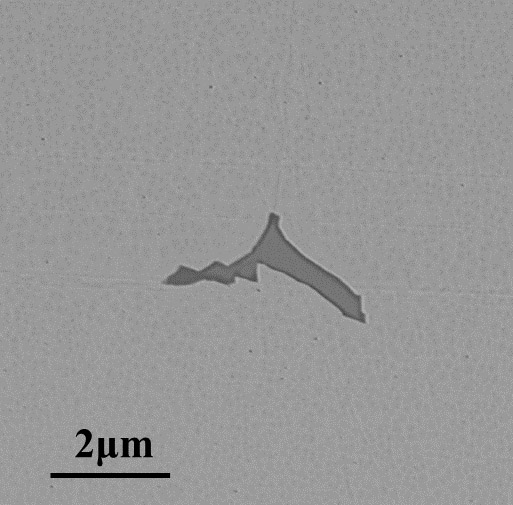

Image

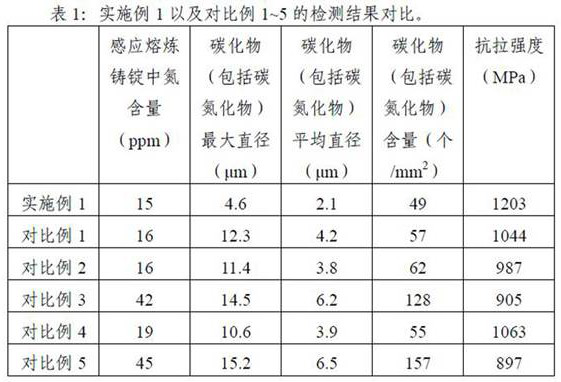

Examples

Embodiment 1

[0056] The vacuum induction melting ingot specification of GH4738 superalloy is φ508mm, and the vacuum self-consumption melting ingot specification is φ560mm (that is, the diameter of the final GH4738 ingot is φ560mm). The specific process includes the following steps:

[0057] ① Using pure nickel plate, pure chromium block, pure cobalt plate, pure tungsten bar, electrode carbon, pure molybdenum block, pure aluminum block, sponge titanium, iron-boron alloy, and sponge zirconium as raw materials, the crucible is nickel-washed before smelting. GB / T 14992-2005 Classification and Designation of High-temperature Alloys and Intermetallic High-Temperature Materials" as the standard, add pure nickel plate, pure chromium block, pure cobalt plate, pure tungsten bar, electrode carbon, pure molybdenum block in sequence according to the proportion, and vacuumize To <0.05Pa, power transmission smelting, after melting, power frequency stirring for 20min, sequentially add sponge titanium, pure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com