A kind of preparation method of methylaminoacetonitrile hydrochloride

A technology of methylaminoacetonitrile hydrochloride and methylamine hydrochloride, which is applied in the field of preparation of methylaminoacetonitrile hydrochloride, can solve the problems of high operation risk, long reaction steps, large equipment investment, etc., and achieve low operation risk factor , low cost, less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

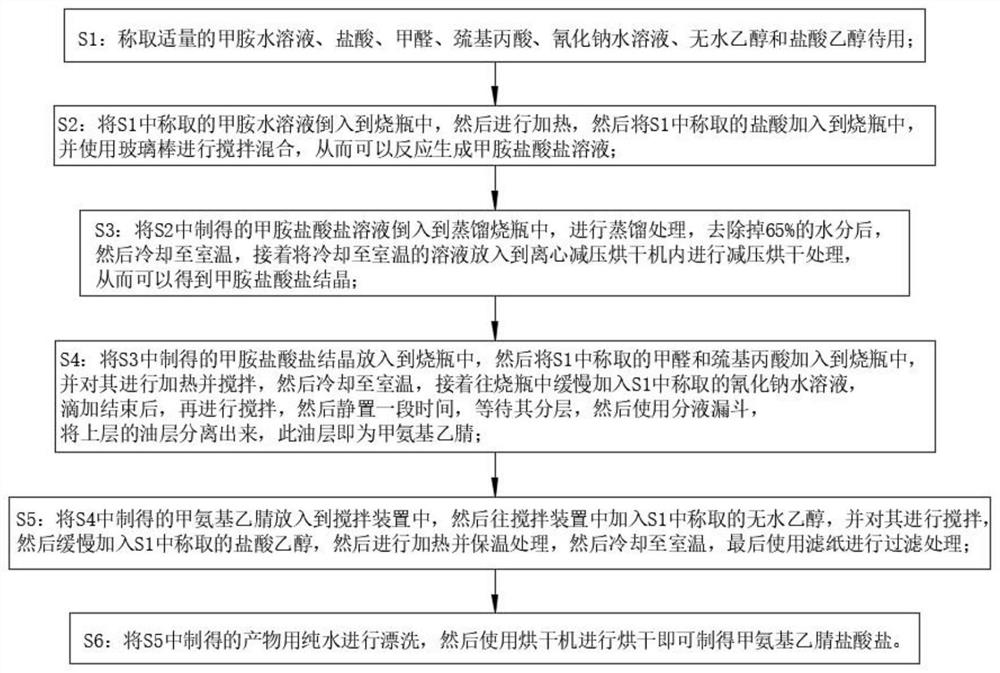

[0032] see figure 1 , the present invention provides the following technical solutions: a preparation method of methylaminoacetonitrile hydrochloride, comprising the following steps:

[0033] S1: Weigh 1200㎎ methylamine aqueous solution, 1150㎎ hydrochloric acid, 1325㎎ formaldehyde, 35㎎ acetic acid, 1850㎎ sodium cyanide aqueous solution, 635㎎ anhydrous ethanol and 545㎎ hydrochloric acid ethanol for use;

[0034] S2: Pour the 1200㎎ methylamine aqueous solution weighed in S1 into the flask, then heat it, then add the 1150㎎ hydrochloric acid weighed in S1 into the flask, and use a glass rod to stir and mix, so that the reaction can generate Methylamine hydrochloride solution;

[0035] S3: Pour the methylamine hydrochloride solution prepared in S2 into a distillation flask, carry out distillation treatment, remove 65% of the water, then cool to room temperature, and then put the solution cooled to room temperature into a centrifugal reducer Drying under reduced pressure is carrie...

Embodiment 2

[0047] see figure 1 , the present invention provides the following technical solutions: a preparation method of methylaminoacetonitrile hydrochloride, comprising the following steps:

[0048] S1: Weigh 1200㎎ methylamine aqueous solution, 1150㎎ hydrochloric acid, 1325㎎ formaldehyde, 35㎎ acetic acid, 1850㎎ sodium cyanide aqueous solution, 635㎎ anhydrous ethanol and 545㎎ hydrochloric acid ethanol for use;

[0049] S2: Pour the 1200㎎ methylamine aqueous solution weighed in S1 into the flask, then heat it, then add the 1150㎎ hydrochloric acid weighed in S1 into the flask, and use a glass rod to stir and mix, so that the reaction can generate Methylamine hydrochloride solution;

[0050] S3: Pour the methylamine hydrochloride solution prepared in S2 into a distillation flask, carry out distillation treatment, remove 65% of the water, then cool to room temperature, and then put the solution cooled to room temperature into a centrifugal reducer Drying under reduced pressure is carrie...

Embodiment 3

[0059] see figure 1 , the present invention provides the following technical solutions: a preparation method of methylaminoacetonitrile hydrochloride, comprising the following steps:

[0060] S1: Weigh 1200㎎ methylamine aqueous solution, 1150㎎ hydrochloric acid, 1325㎎ formaldehyde, 35㎎ acetic acid, 1850㎎ sodium cyanide aqueous solution, 635㎎ anhydrous ethanol and 545㎎ hydrochloric acid ethanol for use;

[0061] S2: Pour the 1200㎎ methylamine aqueous solution weighed in S1 into the flask, then heat it, then add the 1150㎎ hydrochloric acid weighed in S1 into the flask, and use a glass rod to stir and mix, so that the reaction can generate Methylamine hydrochloride solution;

[0062] S3: Pour the methylamine hydrochloride solution prepared in S2 into a distillation flask, carry out distillation treatment, remove 65% of the water, then cool to room temperature, and then put the solution cooled to room temperature into a centrifugal reducer Drying under reduced pressure is carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com