Radiation protection composite material and preparation method thereof

A composite material and radiation protection technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of corrosion resistance, heavy aluminum-based radiation protection materials, secondary radiation, etc., to avoid Corrosion, excellent mechanical properties, effect of reducing mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

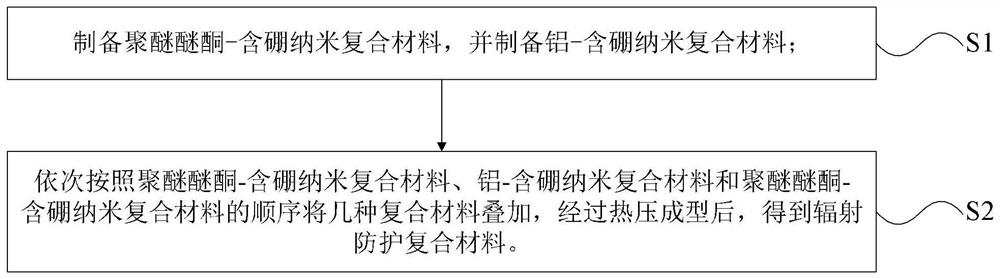

[0042] combine figure 2 As shown, the present invention provides the preparation method of above-mentioned radiation protection composite material, comprises the steps:

[0043] Step S1, preparing polyetheretherketone-boron-containing nanocomposite material, and preparing aluminum-boron-containing nanocomposite material;

[0044] Step S2, stacking several composite materials in sequence according to the order of polyetheretherketone-boron-containing nanocomposite material, aluminum-boron-containing nanocomposite material, and polyetheretherketone-boron-containing nanocomposite material, and after hot-press molding, to obtain Radiation protection composites.

[0045] Specifically, in step S1, the preparation of polyetheretherketone-boron-containing nanocomposites includes: adding boron-containing nanomaterials to polyetheretherketone powder, and obtaining uniformly mixed doped powder by ball milling, and the doped powder The polyetheretherketone-boron-containing nanocomposit...

Embodiment 1

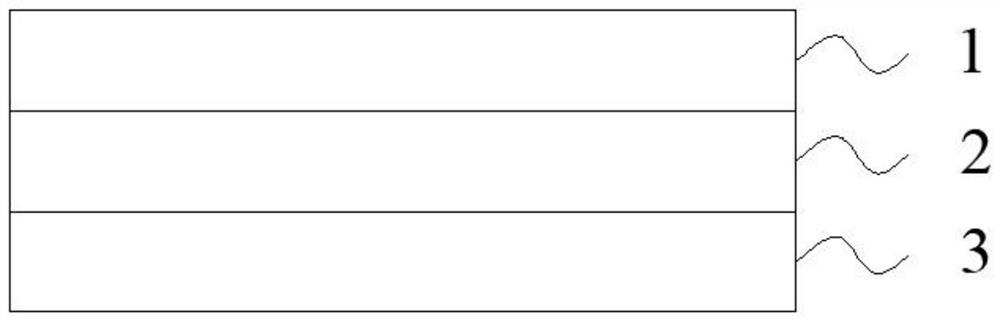

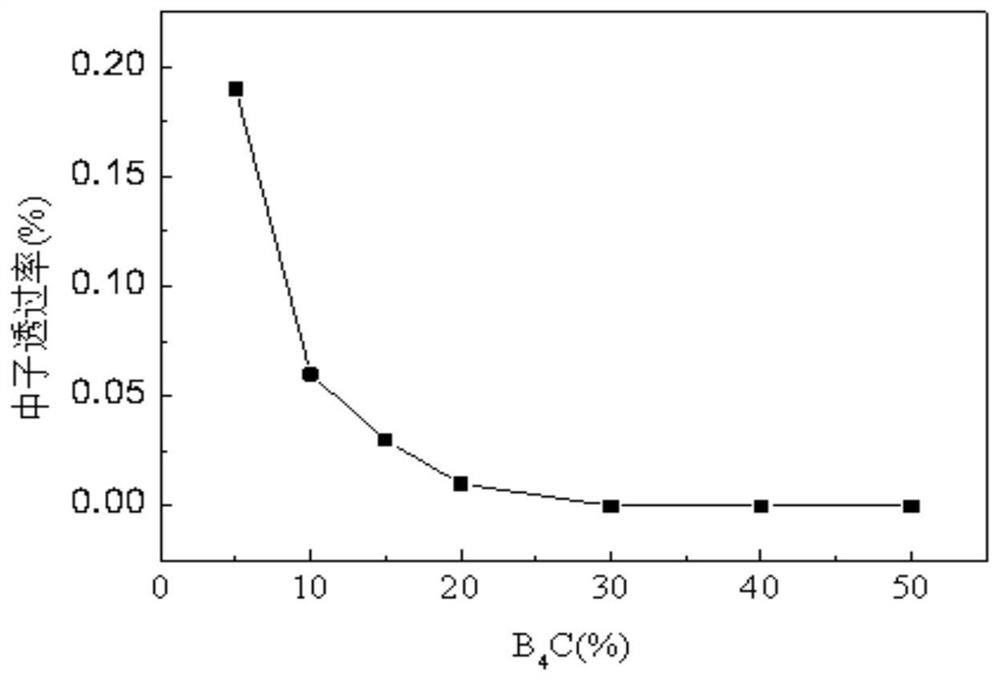

[0059] This embodiment provides a radiation protection composite material. The radiation protection composite material uses polyether ether ketone-boron-containing nanocomposite material as the surface layer, uses aluminum-boron-containing nanocomposite material as the middle layer, and the opposite sides of the middle layer Both are equipped with a surface layer, wherein the thickness of one side of the polyetheretherketone-boron-containing nanocomposite material is 1mm (that is, the thickness of the upper and lower layers is 1mm), and the thickness of the aluminum-boron-containing nanocomposite material is 3mm, and The boron-containing nanomaterials in polyetheretherketone-boron-containing nanocomposites and aluminum-boron-containing nanocomposites are both nano-boron carbide (hereinafter referred to as B 4 C), and B 4 The doping amount of C is 5wt%.

[0060] This embodiment also provides a method for preparing a radiation protection composite material, comprising the follo...

Embodiment 2

[0065] This embodiment provides a radiation protection composite material. The radiation protection composite material uses polyether ether ketone-boron-containing nanocomposite material as the surface layer, uses aluminum-boron-containing nanocomposite material as the middle layer, and the opposite sides of the middle layer Both are equipped with a surface layer, wherein the thickness of one side of the polyetheretherketone-boron-containing nanocomposite material is 1mm, the thickness of the aluminum-boron-containing nanocomposite material is 1mm, and the polyetheretherketone-boron-containing nanocomposite material and aluminum -The boron-containing nanomaterials in the boron-containing nanocomposite material are all nano boron nitride, and the doping amount of the nano boron nitride is 10wt%.

[0066] This embodiment also provides a method for preparing a radiation protection composite material, comprising the following steps:

[0067] 2.1 Add nano-boron nitride to polyether...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com