Method for preparing flexible circuit board based on liquid crystal polymer film

A technology of flexible circuit boards and liquid crystal polymers, applied in chemical/electrolytic methods to remove conductive materials, printed circuits, printed circuit manufacturing, etc., can solve problems such as defects in the forming holes of flexible metal-clad plates, and achieve bending resistance Good foldability, good practicability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

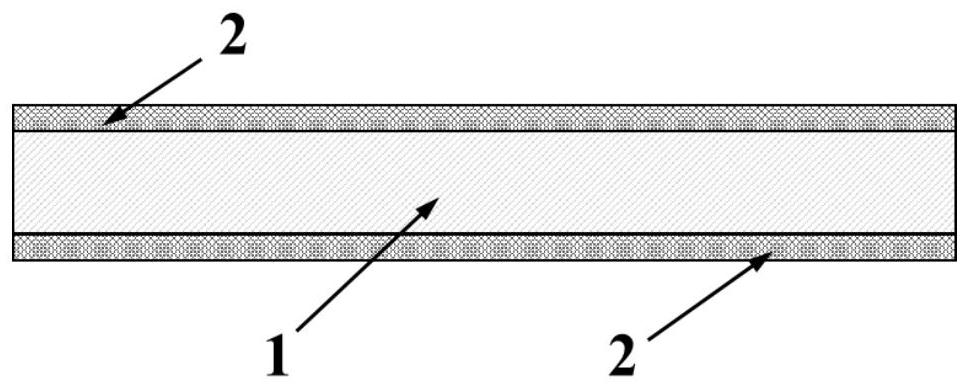

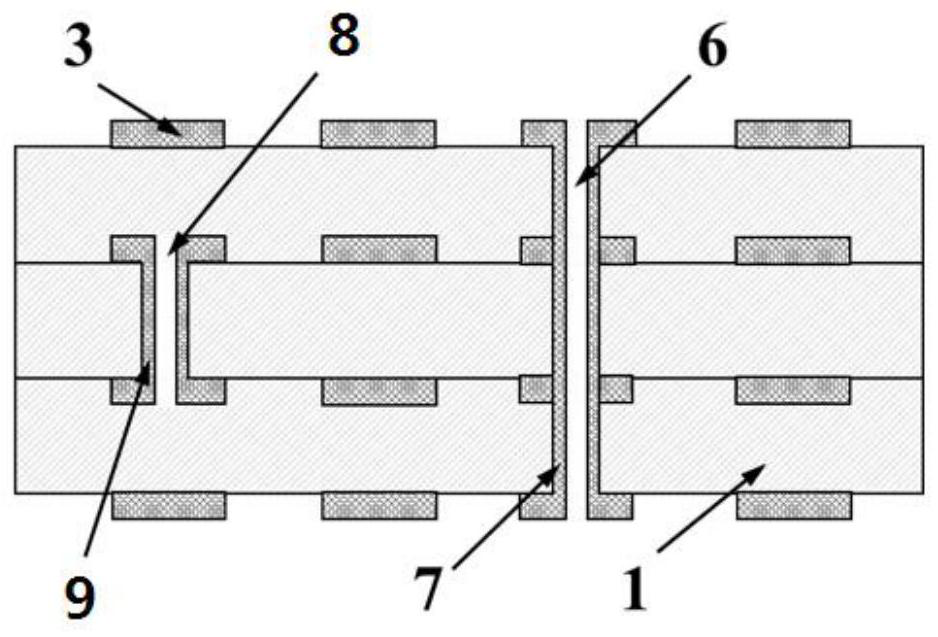

[0078] The liquid crystal polymer material is a liquid crystal copolyester of p-hydroxybenzoic acid and 6-hydroxy-2-naphthoic acid with a melting point of 280°C, and the liquid crystal polymer material is dried and pretreated in a vacuum drying oven at a drying temperature of 150°C. The drying time is 5 hours, and the water content of the resin after drying is less than 400ppm. Using a multi-layer co-extrusion blown film device, the liquid crystal polymer was melt-extruded to form a film. Under the conditions of a traction ratio of 10 and an inflation ratio of 4, a film with a melting point of 280°C and a thickness of 25 μm was obtained. The above film was placed in a high-temperature blast drying oven and treated at 260°C for 6 hours. After the treatment, the modulus adjustment process was completed at a cooling rate of 3°C / min, and the melting point of the film became 298°C.

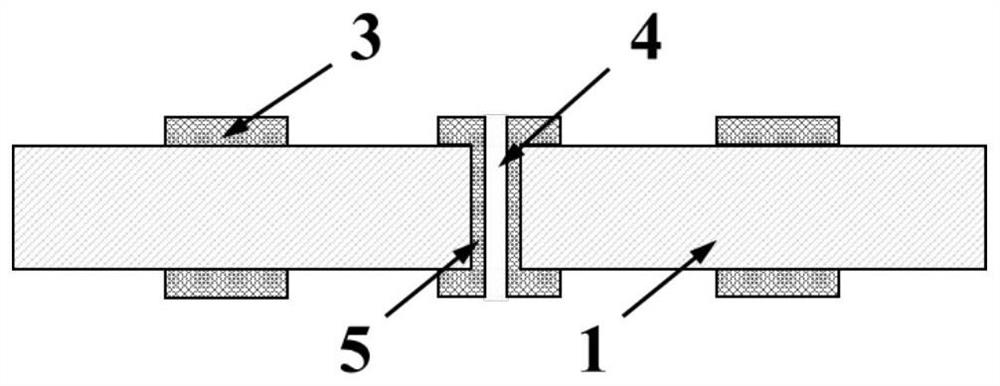

[0079] Two electrolytic copper foils with a thickness of 10 μm and a surface roughness of about 1.5...

Embodiment 2

[0082] The difference from Example 1 is that the thickness of the liquid crystal polymer film 1 is 50 μm.

Embodiment 3

[0084] The difference from Example 1 is that the modulus adjustment process takes 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com