Solvent-free polyurethane adhesive and preparation method thereof

A polyurethane adhesive, solvent-free technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of poor compatibility of resin raw materials, affecting the adhesive performance of the adhesive, affecting the transparency of the adhesive, etc. , to achieve the effects of increasing elongation at break and medium resistance, excellent weather resistance, and excellent hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

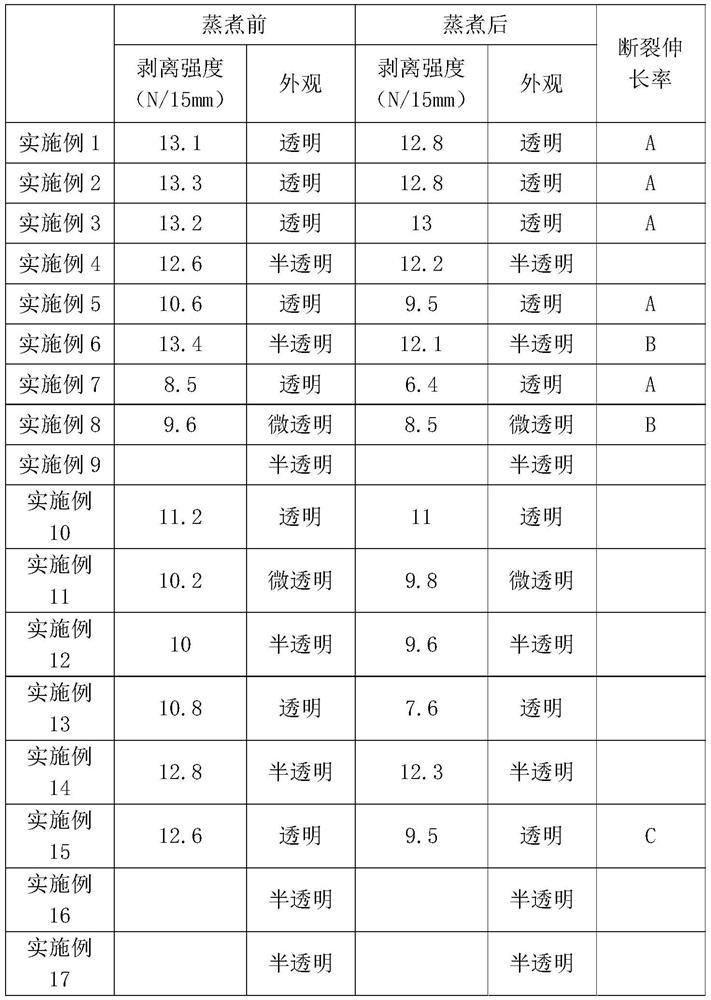

Examples

Embodiment 1

[0069] Embodiment 1 of the present invention specifically provides a solvent-free polyurethane adhesive, the adhesive is composed of A component and B component; the raw materials of the A component include, by weight, 40 parts of polyester polyol , 12 parts of vegetable oil, 5 parts of small molecule polyol; The raw material of described B component comprises, by weight, 60 parts of isocyanate, 7 parts of glass powder;

[0070] The raw material of the A component also includes polyether polyol, and the weight ratio of the polyether polyol to polyester polyol is 1:2;

[0071] Described polyester polyol is adipic acid polyester polyol;

[0072] The adipate polyester polyol is a mixture of polyethylene adipate and polypentylene adipate, and the polydiethylene adipate and polyethylene adipate The weight ratio of pentanediol dioate is 1:1.5;

[0073] The viscosity of the polyethylene adipate at 60°C is 4000cps;

[0074] Described vegetable oil comprises epoxidized soybean oil; ...

Embodiment 2

[0086] Embodiment 2 of the present invention specifically provides a solvent-free polyurethane adhesive, the adhesive is composed of A component and B component; the raw materials of the A component include, by weight, 50 parts of polyester polyol , 20 parts of vegetable oils, 8 parts of small molecular polyols; the raw materials of the B component include, in parts by weight, 80 parts of isocyanates and 10 parts of glass powder;

[0087] The raw material of the A component also includes polyether polyol, and the weight ratio of the polyether polyol to polyester polyol is 1:3;

[0088] Described polyester polyol is adipic acid polyester polyol;

[0089] The adipate polyester polyol is a mixture of polyethylene adipate and polypentylene adipate, and the polydiethylene adipate and polyethylene adipate The weight ratio of pentylene glycol diacid is 1:2;

[0090] The viscosity of the polyethylene adipate at 60°C is 6000cps;

[0091] Described vegetable oil comprises epoxidized ...

Embodiment 3

[0103]Embodiment 3 of the present invention specifically provides a solvent-free polyurethane adhesive, the adhesive is composed of A component and B component; the raw materials of the A component include, by weight, 45 parts of polyester polyol , 18 parts of vegetable oils, 6 parts of small molecular polyols; the raw materials of the B component include, in parts by weight, 70 parts of isocyanates and 8 parts of glass powder;

[0104] The raw material of the A component also includes polyether polyol, and the weight ratio of the polyether polyol to polyester polyol is 1:2.5;

[0105] Described polyester polyol is adipic acid polyester polyol;

[0106] The adipate polyester polyol is a mixture of polyethylene adipate and polypentylene adipate, and the polydiethylene adipate and polyethylene adipate The weight ratio of pentanediol dioate is 1:1.8;

[0107] The viscosity of the polyethylene adipate at 60°C is 5000cps;

[0108] Described vegetable oil comprises epoxidized soy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com