Low-thermal-conductivity outer wall glass wool board and production process

A glass wool board and production process technology, applied in building components, applications, household appliances, etc., can solve the problems of the thermal insulation performance and water absorption discount of inorganic materials, the inability to achieve B1 level of organic materials, and the difficulty of vacuum insulation board operation. Reduce fire hazards, reduce the risk of falling off, and improve the effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The density of glass wool board for low thermal conductivity exterior wall is 140 / m 3 , the compressive strength is 150kpa, the tensile strength is 0.1mpa, the water absorption rate is 9%, and the thermal conductivity is 0.038w / m*k.

[0022] Low thermal conductivity exterior wall glass wool board and its production process:

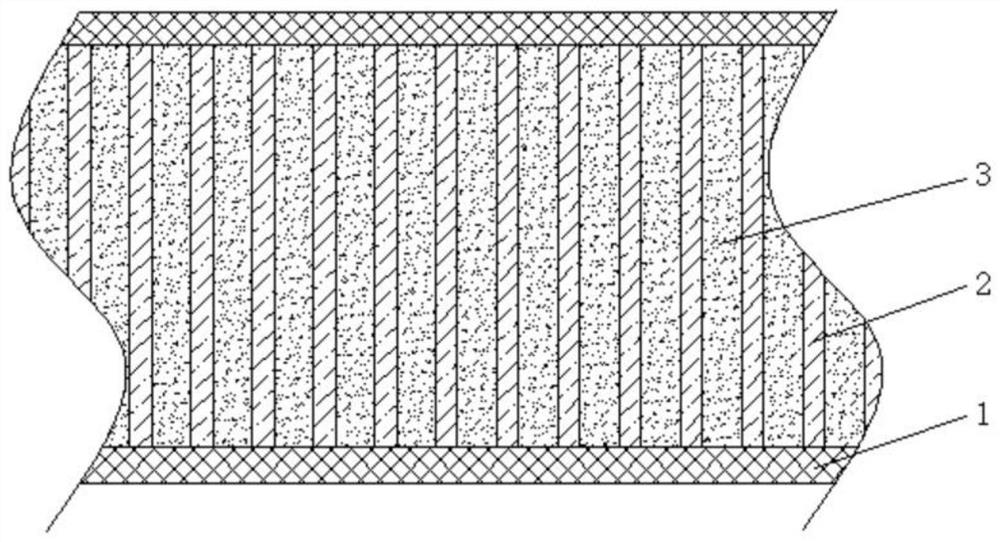

[0023] ①Choose 90kg / m 3 The vertical glass wool 2, the vertical structure can better increase the compressive strength and pulling strength, and it is easy to bond firmly with the slurry 3;

[0024] ②Slurry preparation: Slurry 3 contains 120 parts of fly ash, 150 parts of desulfurized gypsum, 40 parts of fluorite, 1 part of cellulose ether, 18 parts of dodecyl alcohol ester, 18 parts of latex, 5 parts of water repellent, A certain amount of airgel powder, a certain amount of foaming agent, and an appropriate amount of water to form a thin and thick slurry 3;

[0025] ③Infiltration process: the slurry is poured into the fiber gap of the vertical ...

Embodiment 2

[0029] The density of glass wool board for low thermal conductivity exterior wall is 150 / m 3 , The compressive strength is 150kpa, the tensile strength is 0.1mpa, the water absorption rate is 8%, and the thermal conductivity is 0.039w / m*k.

[0030] Low thermal conductivity exterior wall glass wool board and its production process:

[0031] ①Choose 90kg / m 3 The vertical glass wool 2, the vertical structure can better increase the compressive strength and pulling strength, and it is easy to bond firmly with the slurry 3;

[0032] ②Slurry preparation: Slurry 3 contains 150 parts of fly ash, 175 parts of desulfurized gypsum, 50 parts of fluorite, 2 parts of cellulose ether, 20.5 parts of dodecyl alcohol ester, 20.5 parts of latex, 6.5 parts of water repellent, A certain amount of airgel powder, a certain amount of foaming agent, and an appropriate amount of water to form a thin and thick slurry 3;

[0033] ③Infiltration process: The slurry is poured into the fiber gap of the ve...

Embodiment 3

[0037] The density of glass wool board for low thermal conductivity exterior wall is 160 / m 3 , The compressive strength is 150kpa, the tensile strength is 0.1mpa, the water absorption rate is 7%, and the thermal conductivity is 0.04w / m*k.

[0038] Low thermal conductivity exterior wall glass wool board and its production process:

[0039] ①Choose 90kg / m 3 The vertical glass wool 2, the vertical structure can better increase the compressive strength and pulling strength, and it is easy to bond firmly with the slurry 3;

[0040] ②Slurry preparation: Slurry 3 contains 180 parts of fly ash, 200 parts of desulfurized gypsum, 60 parts of fluorite, 3 parts of cellulose ether, 23 parts of dodecyl alcohol ester, 23 parts of latex, 8 parts of water repellent, A certain amount of airgel powder, a certain amount of foaming agent, and an appropriate amount of water to form a thin and thick slurry 3;

[0041] ③Infiltration process: The slurry is poured into the fiber gap of the vertical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com