Tin oxide-hard carbon composite negative electrode material, and preparation method and application thereof

A technology of tin oxide and negative electrode materials, which is applied in the field of tin oxide-hard carbon composite negative electrode materials and its preparation, can solve the problems that cannot completely solve the problem of alloyed negative electrode expansion, and achieve the convenience of large-scale application and operability Strong, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method for a tin oxide-hard carbon composite negative electrode material, comprising the steps of:

[0038] Preparation of sacrificial templates by emulsion polymerization:

[0039] Under the condition of 80°C, add 0.5g sodium lauryl sulfate and 0.2g sodium bicarbonate into 250ml deionized water and stir, then drop 40ml styrene monomer and 0.1g potassium persulfate into the solution, stir for 14 hour, obtain polystyrene macromolecule sacrificial templating agent;

[0040] Mix 2g of catechol and 2ml of 37%wt formaldehyde solution in 80ml of deionized water, add 1g of sodium stannate and 20ml of sacrificial template solution, mix and stir to prepare the precursor solution;

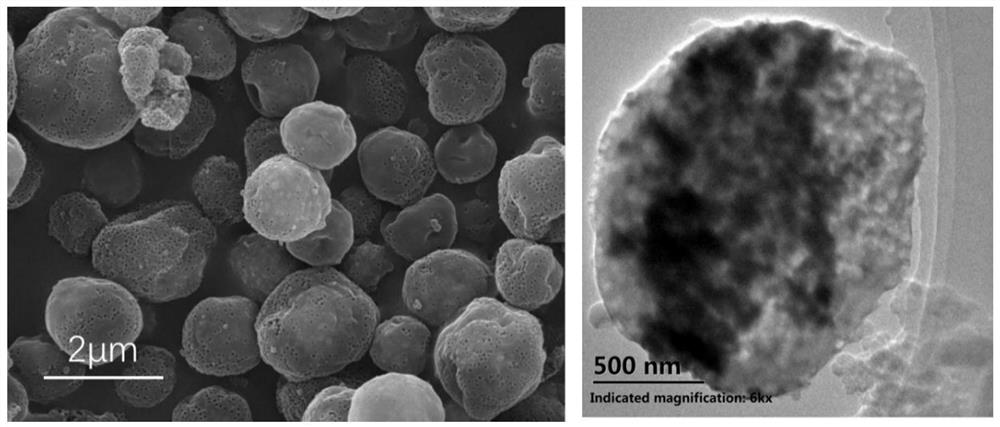

[0041] The precursor solution is granulated by spray drying method to obtain precursor particles. The spray drying is air flow type, the inlet air temperature is 180°C, the outlet air temperature is 60°C, and the feed rate is 2ml / s;

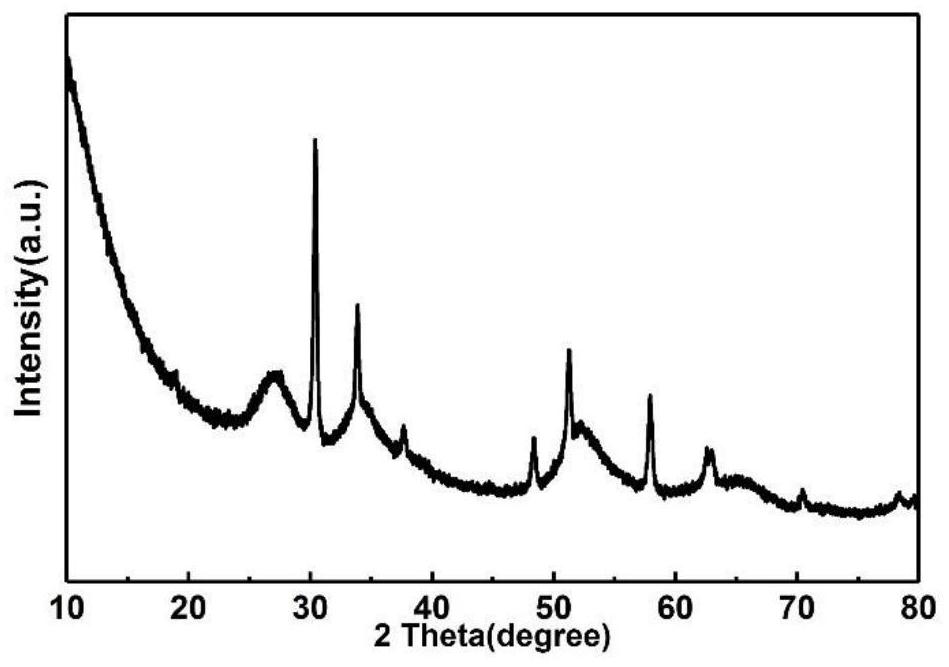

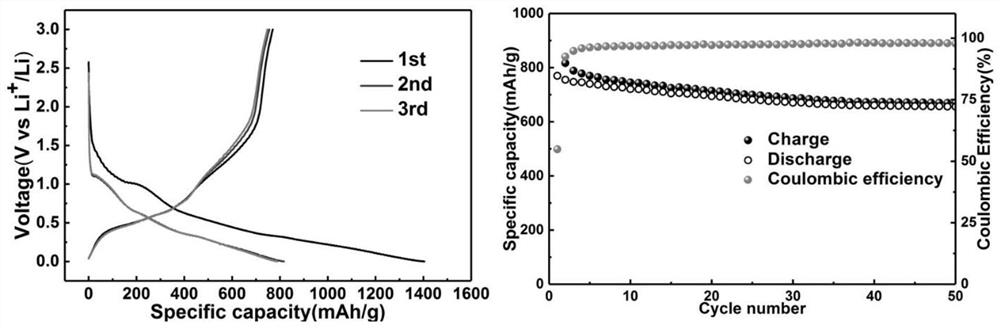

[0042] The precursor particles were calcined at 550...

Embodiment 2

[0055] A preparation method for a tin oxide-hard carbon composite negative electrode material, comprising the steps of:

[0056] Preparation of sacrificial templates by emulsion polymerization:

[0057] Under the condition of 80°C, add 0.5g sodium lauryl sulfate and 0.2g sodium bicarbonate into 250ml deionized water and stir, then drop 40ml styrene monomer and 0.1g potassium persulfate into the solution, stir for 14 hour, obtain polystyrene macromolecule sacrificial templating agent;

[0058] Mix 2g of catechol and 2ml of 37%wt formaldehyde solution in 80ml of deionized water, add 1g of sodium stannate and 20ml of sacrificial template solution, mix and stir to prepare the precursor solution;

[0059] The precursor solution is granulated by spray drying method to obtain precursor particles. The spray drying is air flow type, the inlet air temperature is 180°C, the outlet air temperature is 60°C, and the feed rate is 2ml / s;

[0060] Precursor particles were calcined at 500°C f...

Embodiment 3

[0062] A preparation method for a tin oxide-hard carbon composite negative electrode material, comprising the steps of:

[0063] Preparation of sacrificial templates by emulsion polymerization:

[0064] Under the condition of 80°C, add 0.5g sodium lauryl sulfate and 0.2g sodium bicarbonate into 250ml deionized water and stir, then drop 40ml styrene monomer and 0.1g potassium persulfate into the solution, stir for 14 hour, obtain polystyrene macromolecule sacrificial templating agent;

[0065] Mix 2g of phenol and 1ml of 80%wt furfural solution in 80ml of deionized water, add 1g of sodium stannate and 20ml of sacrificial template solution, mix and stir to prepare the precursor solution;

[0066] The precursor solution is granulated by spray drying method to obtain precursor particles. The spray drying is air flow type, the inlet air temperature is 200°C, the outlet air temperature is 60°C, and the feed rate is 2ml / s;

[0067] The precursor particles were calcined at 550° C. f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com