Ultrahigh-strength steel wire for electric arc additive manufacturing and preparation method

An additive manufacturing and ultra-high-strength steel technology, applied in the direction of additive manufacturing, additive processing, etc., can solve the constraints on the application and promotion of ultra-high-strength steel arc additive manufacturing technology, the lack of ultra-high-strength steel wire, and the low rate of additive manufacturing. problems, to achieve the effect of low wire drawing cost, high arc additive manufacturing efficiency, and fast forming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

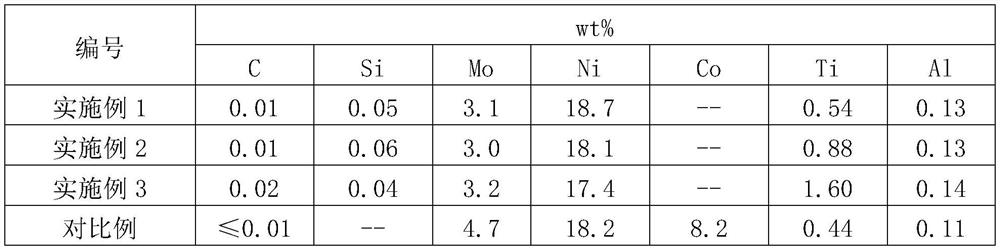

Embodiment 1

[0035]1) Smelting and casting: Use a vacuum smelting furnace to first smelt ultra-high-strength steel wire alloy ingots, with a vacuum of 12 Pa, and cast to obtain an initial melting ingot; heat the initial melting ingot at 1150°C for 5 hours, and forge it into a Φ75mm For the electrode sample, the final forging temperature is not lower than 950℃, and the alloy is smelted twice by electroslag remelting, the electroslag speed is 1.6kg / min, the voltage is 30V, the current is 1.8kA, and the final ingot is obtained by casting.

[0036]2) Forging: The final ingot is forged at 1150℃ for 2h to form a 50mm×50mm square bar, the final forging temperature is not lower than 950℃, and then air-cooled.

[0037]3) Rolling: The forged square bar is kept at 1100°C for 2h, and then rolled into Φ6.5 wire rod after multiple passes of hot continuous rolling.

[0038]4) Annealing: Keep the wire rod at 1100°C for 1 hour, and then air cool.

[0039]5) Drawing: The wire rods softened by heat treatment are mechanically ...

Embodiment 2

[0043]1) Smelting and casting: Use a vacuum smelting furnace to first smelt ultra-high-strength steel wire alloy ingots, with a vacuum of 15 Pa, and casting to obtain an initial melting ingot; heat the initial melting ingot at 1200°C for 6 hours, and forging into a Φ70mm For the electrode sample, the final forging temperature is not less than 950℃, and the alloy is smelted twice by electroslag remelting, the electroslag speed is 1.8kg / min, the voltage is 35V, the current is 2.0kA, and the final ingot is obtained by casting.

[0044]2) Forging: The final ingot is forged at 1150℃ for 4h into a square bar of 50mm×50mm, the final forging temperature is not lower than 950℃, and then air-cooled.

[0045]3) Rolling: The forged square bar is kept at 1100°C for 2h, and then rolled into Φ6.5 wire rod after multiple passes of hot continuous rolling.

[0046]4) Annealing: Keep the wire rod at 1200°C for 2h, and then air cool.

[0047]5) Drawing: The wire rods softened by heat treatment are mechanically rem...

Embodiment 3

[0051]1) Smelting and casting: Use a vacuum smelting furnace to first smelt ultra-high-strength steel wire alloy ingots, with a vacuum of 12 Pa, and cast the ingots to obtain initial melting ingots; heat the initial melting ingots at 1250°C for 5 hours, and forge them to a diameter of 75 mm For the electrode sample, the final forging temperature is not lower than 950℃, and the alloy is smelted twice by electroslag remelting, the electroslag speed is 1.6kg / min, the voltage is 30V, the current is 2.0kA, and the final ingot is obtained by casting.

[0052]2) Forging: The final ingot is forged at 1150℃ for 4h into a square bar of 50mm×50mm, the final forging temperature is not lower than 950℃, and then air-cooled.

[0053]3) Rolling: The forged square bar is kept at 1100°C for 2h, and then rolled into Φ6.5 wire rod after multiple passes of hot continuous rolling.

[0054]4) Annealing: Keep the wire rod at 1100°C for 2h, then cool in air.

[0055]5) Drawing: The wire rods softened by heat treatment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com