Preparation method of cyclodextrin-based water-based UV resin and application thereof

A cyclodextrin, water-based technology, applied in the field of coatings, can solve VOC problems, environment, health damage, health hazards and other problems, and achieve the effect of simple and convenient preparation process and post-processing, and controllable structure-activity relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

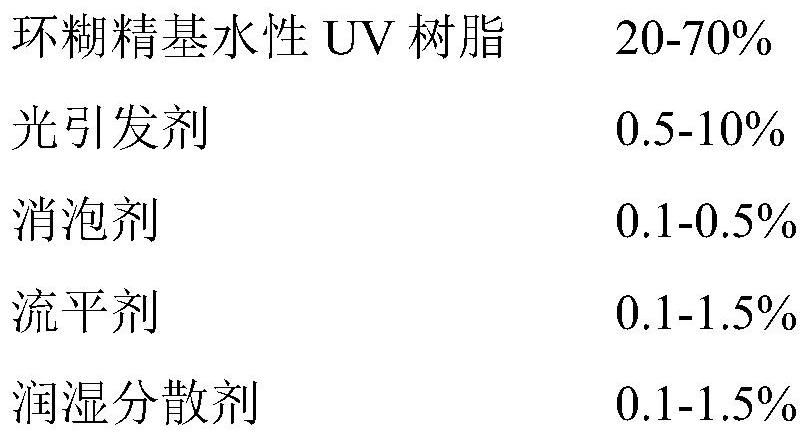

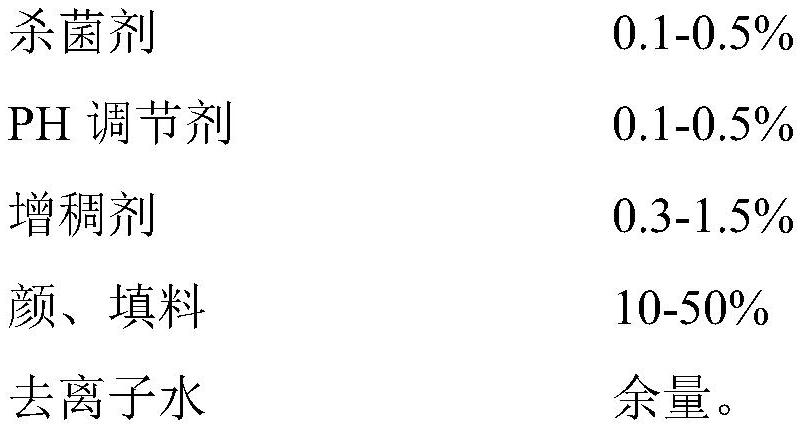

Image

Examples

preparation example Construction

[0040] A preparation method of cyclodextrin-based water-based UV resin, the steps are as follows:

[0041] A. Dissolve cyclodextrin in an organic solvent, add succinic anhydride and 4-dimethylaminopyridine, and stir for reaction. The molar ratio of succinic anhydride and cyclodextrin hydroxyl group is 1:1, and the amount of catalyst added is 0.01%. The temperature is 30°C, and the reaction time is 4h;

[0042] B, after the reaction is finished, filter to remove impurities, dilute with solvent, then extract with aqueous solution, wash, take the aqueous phase solution, and dry to obtain the intermediate product;

[0043] C, the above-mentioned intermediate product is dissolved in deionized water, and agitator, reflux condensation equipment and constant pressure dropping funnel are installed;

[0044] D. Chloropropene Dissolve in the organic solvent 1,4-dioxane, add the solution obtained in step C to the above solution dropwise, control the molar ratio of the halogenated olefi...

Embodiment 2

[0048] A preparation method of cyclodextrin-based water-based UV resin, the steps are as follows:

[0049] A. Dissolve cyclodextrin in an organic solvent, add succinic anhydride and basic catalyst triethylamine, stir and react, the molar ratio of succinic anhydride and cyclodextrin hydroxyl is 3:1, and the amount of catalyst added is 2%. The temperature is 60°C, and the reaction time is 20h;

[0050] B, after the reaction is finished, filter to remove impurities, dilute with solvent, then extract with aqueous solution, wash, take the aqueous phase solution, and dry to obtain the intermediate product;

[0051] C, the above-mentioned intermediate product is dissolved in deionized water, and agitator, reflux condensation equipment and constant pressure dropping funnel are installed;

[0052] D. Halogenated olefins Dissolve in the organic solvent dimethyl sulfoxide, add the solution obtained in step C to the above solution dropwise, heat up to 50°C and react for a period of tim...

Embodiment 3

[0056] A preparation method of cyclodextrin-based water-based UV resin, the steps are as follows:

[0057] A. Dissolve cyclodextrin in an organic solvent, add succinic anhydride and basic catalyst triethylamine, stir and react, the molar ratio of succinic anhydride and cyclodextrin hydroxyl is 5:1, and the amount of catalyst added is 5%, the reaction The temperature is 90°C, and the reaction time is 36h;

[0058] B, after the reaction is finished, filter to remove impurities, dilute with solvent, then extract with aqueous solution, wash, take the aqueous phase solution, and dry to obtain the intermediate product;

[0059] C, the above-mentioned intermediate product is dissolved in deionized water, and agitator, reflux condensation equipment and constant pressure dropping funnel are installed;

[0060] D. Halogenated olefins Dissolve in the organic solvent N-methylpyrrolidone, add the solution obtained in step C to the above solution dropwise, heat up to 60°C and react for a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com