A kind of bifunctional electrochromic energy storage device and its production method

A technology of electrochromic and manufacturing method, applied in instruments, nonlinear optics, optics, etc., can solve problems such as single function and limited Li ion energy density, and achieve the effect of simple and convenient preparation process and steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

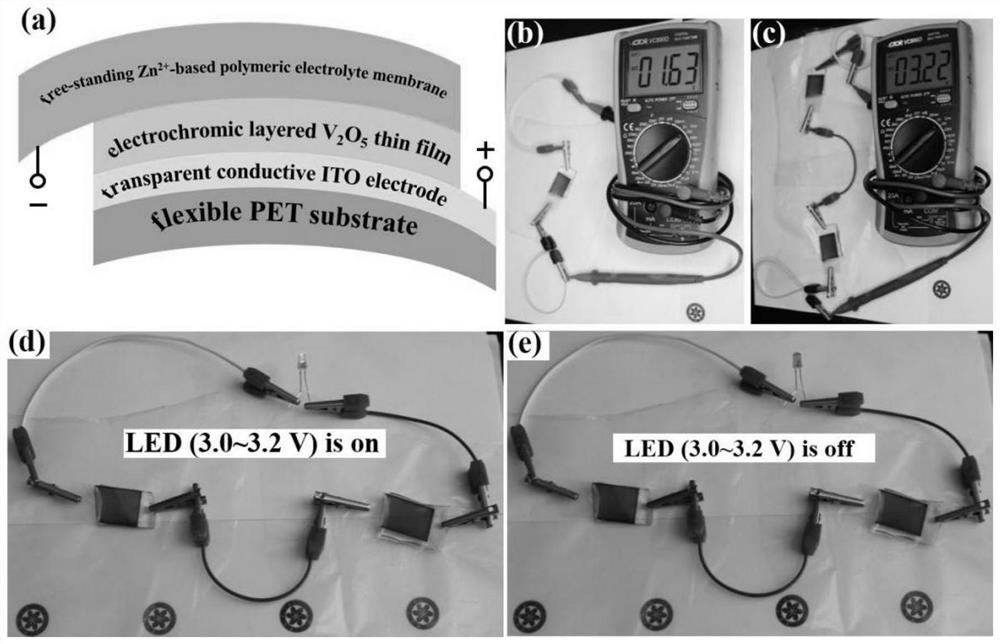

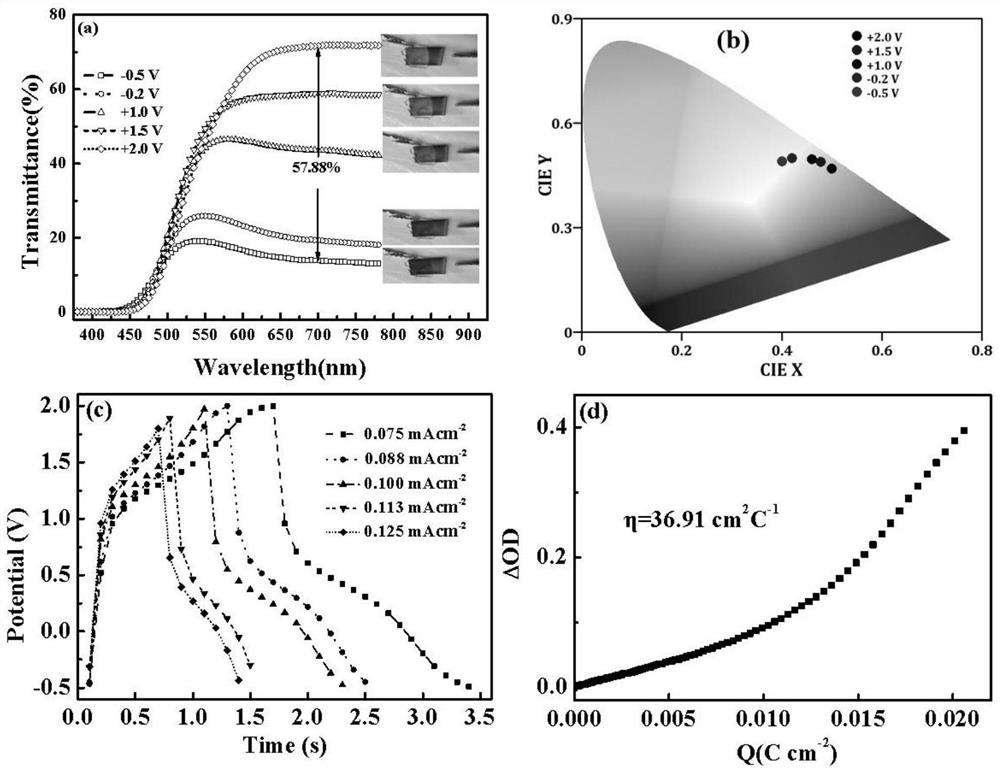

[0046] The dual-function electrochromic energy storage device of this embodiment, such as figure 1 As shown in a, the electrochromic energy storage device includes a substrate (flexible PET substrate) and a functional layer deposited on the substrate. Conductive layer on the substrate (transparent conductive ITO electrode, transparentconductive ITO electrode), intermediate functional layer (electrochromic layer V 2 O 5 Thin film, electrochromic layeredV 2 O 5 thin film) and electrolyte layer (self-supporting Zn 2+ based polymer electrolyte membrane, free-standing Zn 2+ -based polymeric electrolyte membrane).

[0047] The thickness of the ITO conductive layer is 180 nm. The film thickness of the intermediate functional layer is 2000 nm.

[0048] The electrolyte layer is self-supporting Zn 2+ Polyacrylamide hydrogel film layer.

[0049] The membrane thickness of the electrolyte layer is 1.5 mm.

[0050] A preparation method of the above-mentioned bifunctional electroc...

Embodiment 2

[0061] The bifunctional electrochromic energy storage device of this embodiment, the film structure arrangement of the functional layer and the preparation method thereof are basically the same as those of Embodiment 1, the main difference is that the thickness of the ITO conductive layer is 50 nm. The film thickness of the intermediate functional layer is 50 nm. The membrane thickness of the electrolyte layer is 5 μm.

[0062] The electrolyte layer is self-supporting Zn 2+ based polyacrylic hydrogel film layer.

[0063] The step S4 is self-supporting Zn 2+ Preparation of base polyacrylic acid hydrogel film layer: dissolve 0.032mol of zinc acetate in 100ml of deionized water, stir to obtain a salt solution with a concentration of 0.32mol / L, and add 12.48g of methacrylic acid monomer to the salt solution Then add the cross-linking agent ethylene bismethacrylate and the initiator azobisisobutyl cyanide; after stirring evenly, pour it into the mold quickly, and polymerize it a...

Embodiment 3

[0067] The bifunctional electrochromic energy storage device of this embodiment, the film structure arrangement of the functional layer and its preparation method are basically the same as those of Embodiment 1, the main difference is that the thickness of the ITO conductive layer is 300nm. The film thickness of the intermediate functional layer is 5000 nm. The thickness of the membrane layer of the electrolyte layer is 5 mm.

[0068] The electrolyte layer is self-supporting Zn 2+ Polyethylene glycol hydrogel film layer.

[0069] The step S4 is self-supporting Zn 2+ Preparation of polyethylene glycol-based hydrogel film layer: dissolve 0.048 mol of zinc fluoroborate in 100 ml of deionized water, stir to obtain a salt solution with a concentration of 0.48 mol / L, and add 18.6 g of ethylene glycol monomer to the solution. In the salt solution, add the crosslinking agent ethylene glycol dimethacrylate and the initiator di(tert-butylcyclohexyl) peroxydicarbonate; after stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com