A kind of technique for preparing pencil by polystyrene micro-foaming

A polystyrene, micro-foaming technology, used in the production of pencil leads, non-moving pencils, bulk chemicals, etc., can solve problems such as pollution of toxic and harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

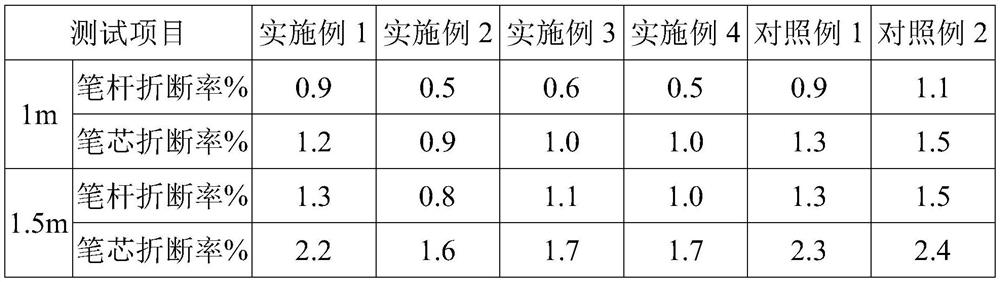

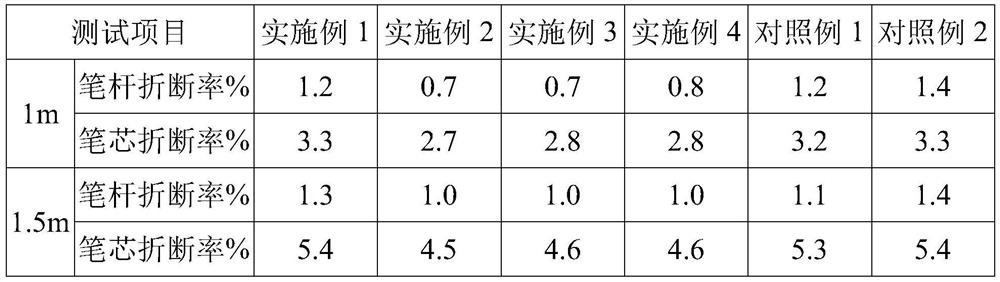

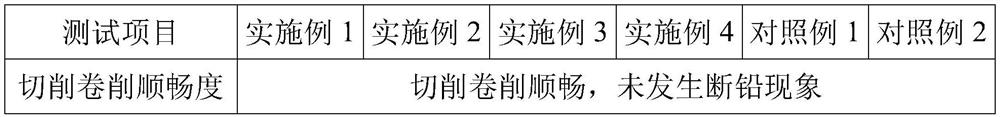

Examples

Embodiment 1

[0030] A kind of technology that polystyrene microfoam prepares pencil, comprises the following steps:

[0031] (1) Refill granulation: weigh 80kg of polystyrene, 15kg of talcum powder, 15kg of thermoplastic elastomer SBS, 80kg of graphite, 0.2kg of zinc stearate, 1.3kg of calcium stearate, and 10kg of monoglyceride stearate After mixing, stir evenly, and then add it to the extruder barrel preheated to 220°C for melting and plasticization. Under the pressure of 120MPa, quickly inject supercritical fluid carbon dioxide into the extruder barrel. In the plastic melt, through the shearing of the screw, the supercritical fluid carbon dioxide is dispersed and homogenized, fully dissolved with the polymer melt to form a single-phase melt, and the pressure at this time is maintained. After saturation and equilibrium, it is extruded and cooled. , made into refill particles;

[0032] (2) Pen skin granulation: weigh 90kg of polystyrene, 27kg of thermoplastic elastomer SBS, 13kg of pigme...

Embodiment 2

[0042] A kind of technology that polystyrene microfoam prepares pencil, comprises the following steps:

[0043] (1) Refill granulation: weigh 80kg of polystyrene, 15kg of talcum powder, 15kg of thermoplastic elastomer SBS, 80kg of graphite, 0.2kg of zinc stearate, 1.3kg of calcium stearate, and 10kg of monoglyceride stearate After mixing, stir evenly, and then add it to the extruder barrel preheated to 220°C for melting and plasticization. Under the pressure of 120MPa, quickly inject supercritical fluid carbon dioxide into the extruder barrel. In the plastic melt, through the shearing of the screw, the supercritical fluid carbon dioxide is dispersed and homogenized, fully dissolved with the polymer melt to form a single-phase melt, and the pressure at this time is maintained. After saturation and equilibrium, it is extruded and cooled. , made into refill particles;

[0044] (2) Pen skin granulation: weigh 90kg of polystyrene, 27kg of thermoplastic elastomer SBS, 13kg of pigme...

Embodiment 3

[0055] A kind of technology that polystyrene microfoam prepares pencil, comprises the following steps:

[0056] (1) Refill granulation: weigh 80kg of polystyrene, 15kg of talcum powder, 15kg of thermoplastic elastomer SBS, 80kg of graphite, 0.2kg of zinc stearate, 1.3kg of calcium stearate, and 10kg of monoglyceride stearate After mixing, stir evenly, and then add it to the extruder barrel preheated to 220°C for melting and plasticization. Under the pressure of 120MPa, quickly inject supercritical fluid carbon dioxide into the extruder barrel. In the plastic melt, through the shearing of the screw, the supercritical fluid carbon dioxide is dispersed and homogenized, fully dissolved with the polymer melt to form a single-phase melt, and the pressure at this time is maintained. After saturation and equilibrium, it is extruded and cooled. , made into refill particles;

[0057] (2) Pen skin granulation: weigh 90kg of polystyrene, 27kg of thermoplastic elastomer SBS, 13kg of pigme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com