Extraction process of high-purity ultralow-viscosity sodium alginate

A sodium alginate and extraction process technology, applied in the field of sodium alginate extraction process, can solve the problem of low purity and achieve the effect of simple operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

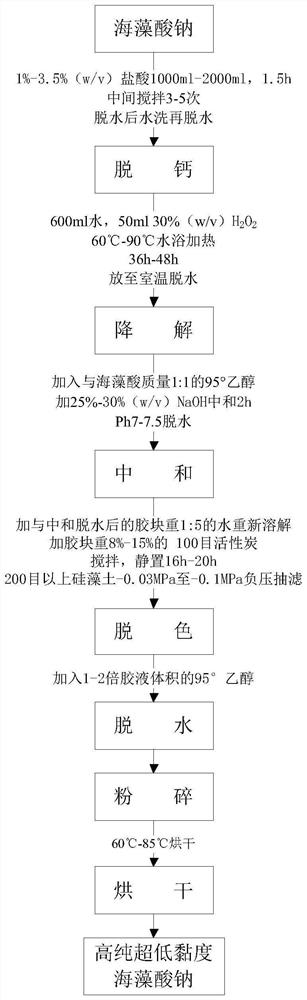

Image

Examples

Embodiment 1

[0052] The first step, decalcification

[0053] Take 200g of 80-mesh sodium alginate, add 1% (w / v) hydrochloric acid 1000mL, soak for 1.5h, stir 4 times in the middle, dehydrate with 400-mesh filter, add 800mL of water, stir and wash once, and then dehydrate with 400-mesh filter to obtain Alginic acid;

[0054] The second step, degradation

[0055] Add 600mL of water to the alginic acid, add 50mL of 30% (w / v) and stir, put it in a 60°C water bath and heat it for degradation for 36h, take it out and put it at room temperature, dehydrate it with a 400-mesh mesh, and obtain the degraded dehydrated acid block;

[0056] The third step, neutralization

[0057] Add 95° ethanol at a ratio of 1:1 to the weight of alginic acid after dehydration and degradation, start stirring, add an appropriate amount of 25% (w / v) NaOH, and after neutralization for 2 hours, use an acidity meter to measure the pH of the ethanol between 7-7.5, 400 mesh net dehydration;

[0058] The fourth step, decol...

Embodiment 2

[0067] The first step, decalcification

[0068] Take 200g of 80-mesh sodium alginate, add 2000mL of 3.5% (w / v) hydrochloric acid, soak for 1.5h, stir 5 times in the middle, dehydrate with a 400-mesh filter, add 1000mL of water to stir and wash once, and then dehydrate with a 400-mesh filter to obtain Alginic acid;

[0069] The second step, degradation

[0070] Add 600mL of water to the alginic acid, add 50mL of 30% (w / v) and stir, put it in a 60°C water bath and heat it for degradation for 48h, take it out and put it at room temperature, dehydrate it with a 400-mesh mesh, and obtain the degraded dehydrated acid block;

[0071] The third step, neutralization

[0072] Add 95° ethanol at a ratio of 1:1 to the weight of alginic acid after dehydration and degradation, start stirring, add an appropriate amount of 30% (w / v) NaOH, neutralize for 2 hours, use an acidity meter to measure the pH of ethanol between 7-7.5, 400 mesh net dehydration;

[0073] The fourth step, decolorizat...

Embodiment 3

[0082] The first step, decalcification

[0083] Take 200g of 80-mesh sodium alginate, add 2000mL of 2% (w / v) hydrochloric acid, soak for 1.5h, stir 5 times in the middle, dehydrate with a 400-mesh filter, add 900mL of water to stir and wash once, and then dehydrate with a 400-mesh filter to obtain Alginic acid;

[0084] The second step, degradation

[0085] Add 600mL of water to the alginic acid, add 50mL of 30% (w / v) and stir, put it in a water bath at 80°C and heat it for degradation for 40h, take it out and let it cool to room temperature, and dehydrate it with a 400-mesh mesh to obtain the degraded dehydrated acid block;

[0086] The third step, neutralization

[0087] Add 95° ethanol at a ratio of 1:1 to the weight of alginic acid after dehydration and degradation, start stirring, add an appropriate amount of 28% (w / v) NaOH, neutralize for 2 hours, use an acidity meter to measure the pH of ethanol between 7-7.5, 400 mesh net dehydration;

[0088] The fourth step, deco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com