A method for online continuous processing of molten titanium-containing blast furnace slag

A treatment method and technology of blast furnace slag, which is applied in the field of online continuous processing of molten titanium-containing blast furnace slag, can solve the problems of large water consumption, increased processing procedures, and waste of heat, so as to reduce energy consumption, solve large-area accumulation and pollute the environment , to avoid the effect of large footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

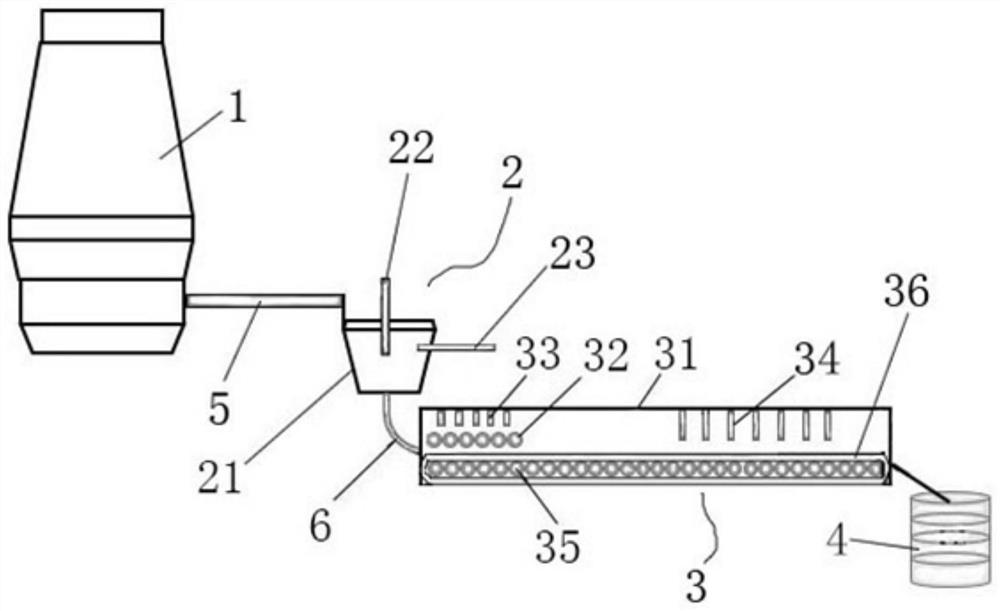

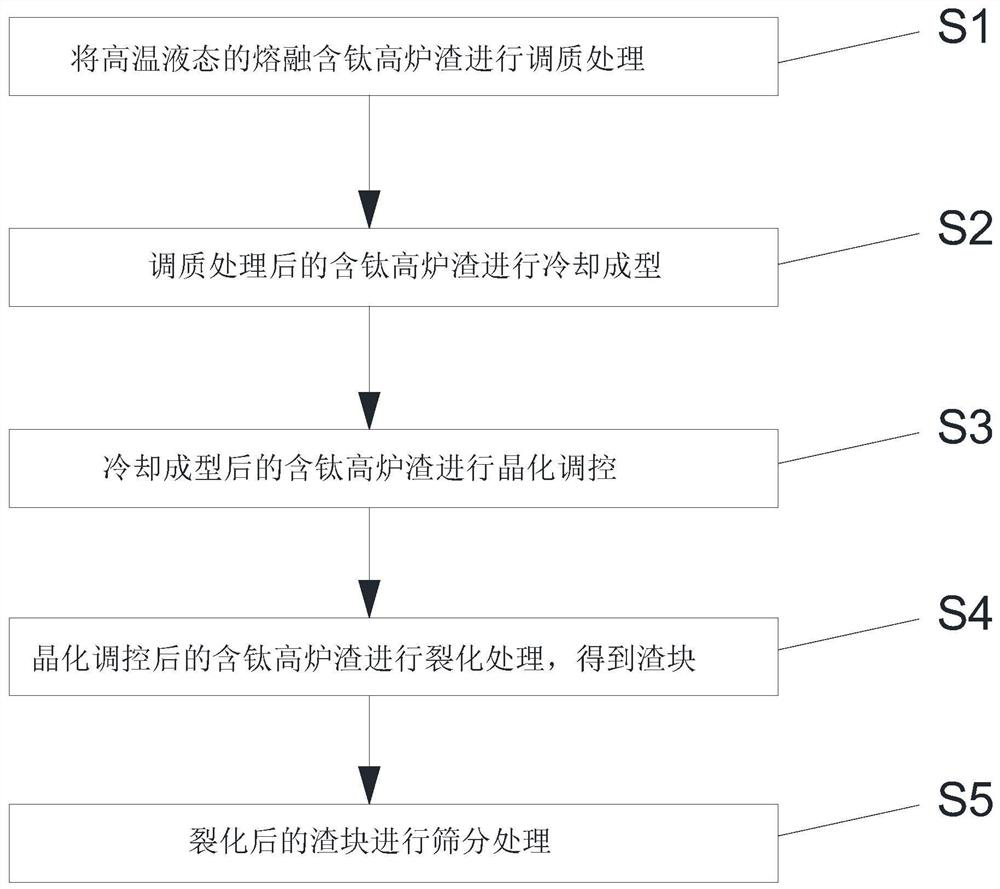

[0059] (1) The high-temperature liquid molten titanium-containing blast furnace slag discharged from the blast furnace 1 enters the quenching and tempering furnace body 21 through the slag ditch 5;

[0060] (2) In the quenching and tempering furnace body 21, 6% quartz sand, 3% alumina powder, 0.5% fluorite tailings and 0.5% ferrochrome slag are added by the feeding pipe 22 in a top-blown manner, while the gas spray gun 23 is heated by combustion and heated to 1450°C;

[0061] (3) The titanium-containing blast furnace slag after quenching and tempering enters the crystallization control furnace body 31 through the guide pipe 6, and the thickness of the titanium-containing blast furnace slag is controlled by the roll 32, and the thickness of the titanium-containing blast furnace slag is controlled to be 10 mm, and is transported The roller 35 drives the bearing plate 36 to transport the titanium-containing blast furnace slag;

[0062] (4) In the process of passing through the r...

Embodiment 2

[0066] (1) The high-temperature liquid molten titanium-containing blast furnace slag discharged from the blast furnace 1 enters the quenching and tempering furnace body 21 through the slag ditch 5;

[0067] (2) In the quenching and tempering furnace body 21, 13% quartz sand, 5% alumina powder, 1% fluorite tailings and 1% ferrochrome slag are added by the feeding pipe 22 in a top-blowing manner, and the gas spray gun 23 is heated by combustion and heated to 1500°C;

[0068] (3) The titanium-containing blast furnace slag after quenching and tempering enters the crystallization control furnace body 31 through the guide pipe 6, and the thickness of the titanium-containing blast furnace slag is controlled by the roll 32, and the thickness of the titanium-containing blast furnace slag is controlled to be 30 mm, and is transported The roller 35 drives the bearing plate 36 to transport the titanium-containing blast furnace slag;

[0069] (4) In the process of passing through the roll...

Embodiment 3

[0073] (1) The high-temperature liquid molten titanium-containing blast furnace slag discharged from the blast furnace 1 enters the quenching and tempering furnace body 21 through the slag ditch 5;

[0074] (2) In the quenching and tempering furnace body 21, 16% of quartz sand, 7% of alumina powder, 1% of fluorite tailings and 1% of ferrochrome tailings are added in a top-blowing manner from the feeding pipe 22, and the gas The spray gun 23 is heated by combustion and heated to 1550°C;

[0075] (3) The titanium-containing blast furnace slag after quenching and tempering enters the crystallization control furnace body 31 through the guide pipe 6, and the thickness of the titanium-containing blast furnace slag is controlled by the roll 32, and the thickness of the titanium-containing blast furnace slag is controlled to be 50mm, and is transported The roller 35 drives the bearing plate 36 to transport the titanium-containing blast furnace slag;

[0076] (4) In the process of pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com