Gelatin-based carbon nanofibers and preparation method thereof

A carbon nanofiber, gelatin-based technology, applied in the field of gelatin-based carbon nanofibers and their preparation, can solve problems such as difficulty in maintaining fiber morphology, and achieve the effects of avoiding coagulation and sedimentation, high porosity and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

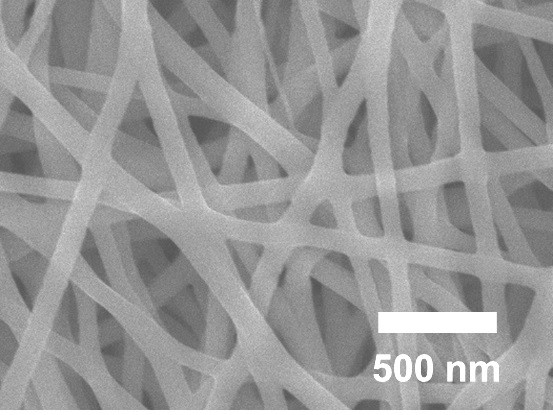

[0034] Add 1.25 g of gelatin solid particles into 7 g of deionized water, heat and stir at 70 °C for 2 h, and prepare an aqueous gelatin solution with a mass fraction of 15%. Add 62.5 mg of sodium iron edetate to the aqueous gelatin solution, the mass ratio of gelatin solid to sodium iron edetate is 20:1, and continue heating and stirring for 2 h. The gelatin / sodium iron ethylenediamine tetraacetate mixed spinning solution obtained above was sucked into a syringe, and then loaded into an electrospinning machine. Under specific spinning parameters (spinning temperature was 70 °C, and the syringe advance rate was 0.53 mL h -1 , the spinning voltage was controlled at 15.0 kV) to obtain gelatin-based fibers by electrospinning. The spun gelatin-based fibers were placed in a muffle furnace under specific pre-oxidation conditions (in an air atmosphere, from room temperature to 5 °C min -1 The heating rate was increased to 150 °C, kept for 2 h, and then at 1 °C min -1 The heating r...

Embodiment 2

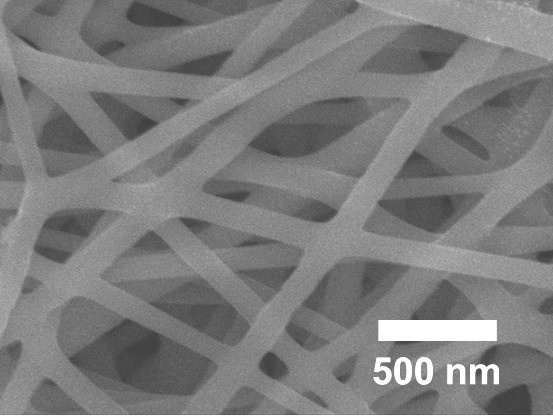

[0036] Change the mass of sodium ferric edetate powder to 125 mg, that is, the mass ratio of gelatin solid to sodium ferric edetate powder is 10:1, and change the propulsion rate of the syringe during spinning to 0.7 mL h -1 , the spinning voltage was controlled to be 18.5kV, and other experimental conditions and processes were the same as in Example 1. The gelatin-based carbon nanofiber that embodiment 2 obtains sees figure 2 shown.

Embodiment 3

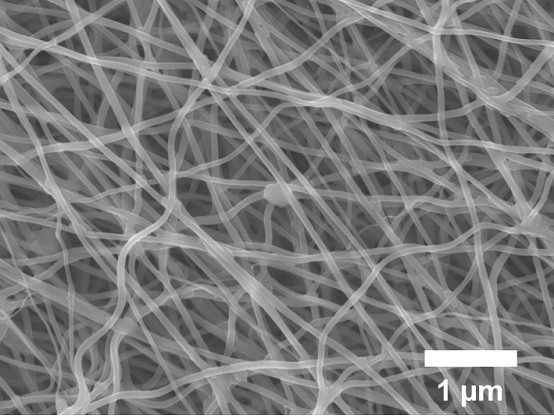

[0038] Add 1.25 g of gelatin solid particles into 7 g of deionized water, heat and stir at 70 °C for 2 h, and prepare an aqueous gelatin solution with a mass fraction of 15%. Add 110 mg of potassium ferricyanide to the aqueous gelatin solution, the mass ratio of gelatin solid to potassium ferricyanide is 125:11, and continue heating and stirring for 2 h. The pre-oxidation conditions were changed to: in air atmosphere, from room temperature to 5 ℃ min -1 The heating rate was increased to 150 °C, kept for 2 h, and then at 1 °C min -1 The heating rate was increased to 310 °C, and the holding time was 1 h. Other experimental conditions and process are identical with embodiment 1. The gelatin-based carbon nanofiber that embodiment 3 obtains sees image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com