Chromium-free passivation composition for galvanized sheet and method for making and using the same

A chrome-free passivation, aluminum-zinc plating technology, applied in the coating process of metal materials, etc., can solve the problem that the chrome-free passivation treatment agent is not suitable for use, and achieve excellent salt spray performance, heat and humidity resistance, and excellent alkali resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

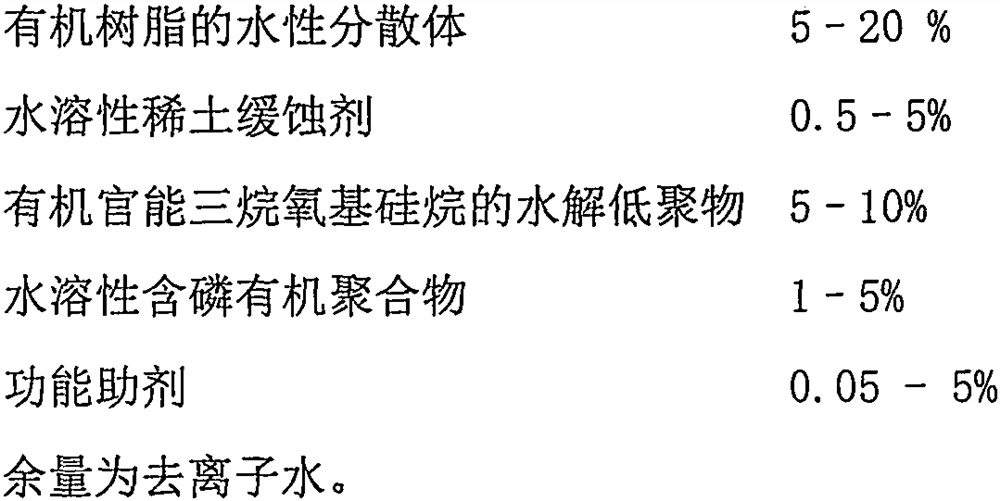

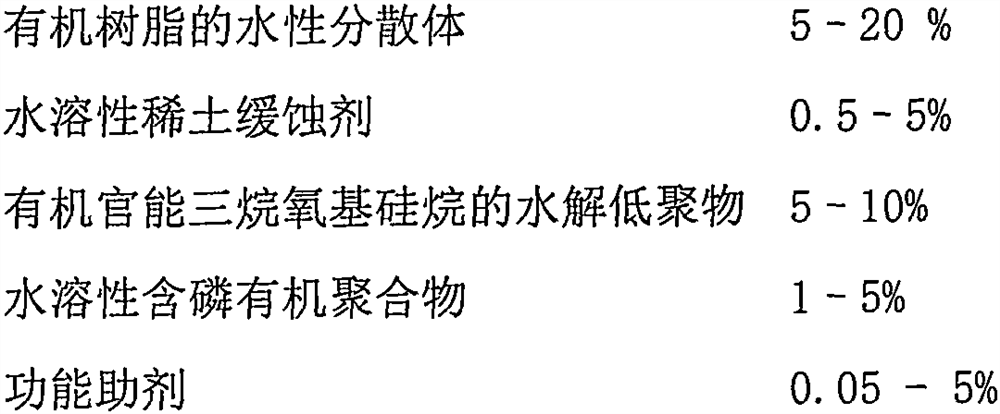

Method used

Image

Examples

Embodiment 1

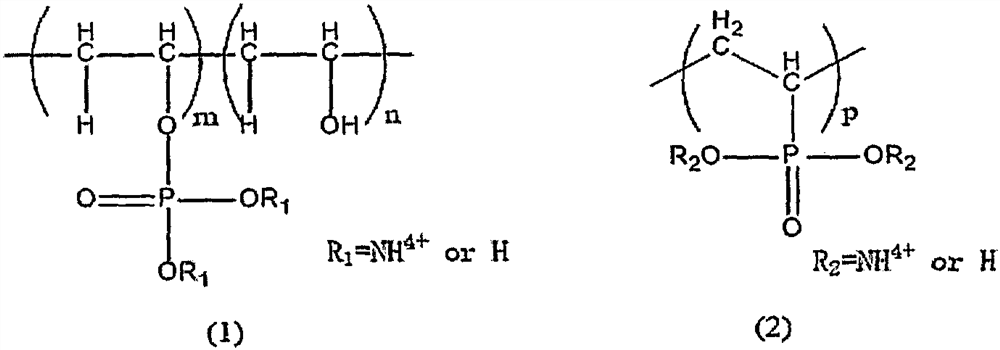

[0049] The preparation method of phosphated polyvinyl alcohol (ammonium dihydrogen, ammonium monohydrogen) in embodiment 1,3,5: get a certain amount of polyvinyl alcohol, deionized water, after dissolving, add appropriate amount of phosphoric acid and urea and stir evenly, Raise the temperature to 110-120°C for 3 hours, then raise the temperature to 150°C and continue the reaction for 30 minutes to obtain a white solid polyvinyl alcohol phosphate-ammonium salt. The crude product is soaked and dried in ethanol first, then crushed, and then extracted by Soxhlet extractor for 8 hours to remove residual phosphoric acid, urea and biuret, etc., and vacuum-dried at 50-60°C for later use.

Embodiment 2

[0050] The preparation method of polyvinylphosphoric acid (ammonium dihydrogen, ammonium monohydrogen) in embodiment 2, 4, 6: take a certain amount of polyvinylphosphoric acid, deionized water, after dissolving, drop a certain amount of ammonia water, after stirring fully and uniformly, obtain Polyvinyl phosphate (ammonium dihydrogen, ammonium monohydrogen) salt. The crude product is firstly precipitated with ethanol to obtain a solid, which is vacuum-dried at 50-60°C for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com