Preparation method and application of molybdenum disulfide/boron-doped graphite-phase carbon nitride composite visible light photocatalyst

A graphite-phase carbon nitride and molybdenum disulfide technology, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen/synthesis gas production, etc., can solve application limitations, low efficiency of photocatalytic water splitting, and charge separation efficiency Low-level problems, to achieve the effect of low cost, less impurities, and complete reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] Step 1: Prepare boron-doped graphite phase carbon nitride powder: weigh 20 g urea, 12 mg PH 4 BNa and 30 mL of water. Put the weighed medicine into a beaker, put it into an ultrasonic disperser and sonicate it for 30 min, then move it to a magnetic stirrer, adjust to a suitable position, and stir at room temperature for 30 min. Then heated in a constant temperature water bath set at 80 °C for 3 h, and evaporated to dryness to obtain a white powder. Put the white powder in a muffle furnace, raise the temperature to 520 °C, set the heating rate to 5 °C / min, and maintain this temperature for 2 h for sintering to obtain boron-doped graphite phase carbon nitride powder.

[0020] Step 2: Prepare molybdenum disulfide powder: 5.3142 g (NH 4 ) 6 Mo 7 o 24 4H 2 O and 9.8195 g of thiourea were vigorously stirred in 150 ml of distilled water. After the formation of a homogeneous solution, it was transferred to a 100 ml hydrothermal kettle and kept at 180°C for 24 hours, and ...

example 2

[0022] Example 2: The difference from Example 1 is that molybdenum disulfide is not added, and a boron-doped graphite phase carbon nitride catalyst sample is prepared.

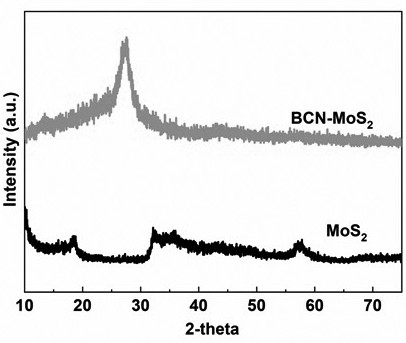

[0023] figure 1 For the photocatalytic hydrogen production average rate figure of the photocatalyst that example 1 and example 2 obtain, figure 2 It is example 1 and the XRD spectrum of molybdenum disulfide, as can be seen from the figure, the present invention obviously improves the hydrogen production of boron-doped graphite phase carbon nitride material through the composite of boron-doped graphite phase carbon nitride and molybdenum disulfide s efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com