Method for preparing flue gas purifying agent from aluminum ash

A purification agent and aluminum ash technology, which is applied in the field of resource utilization of non-ferrous solid waste, can solve the problem that secondary aluminum ash cannot be used in a high-value way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with specific examples.

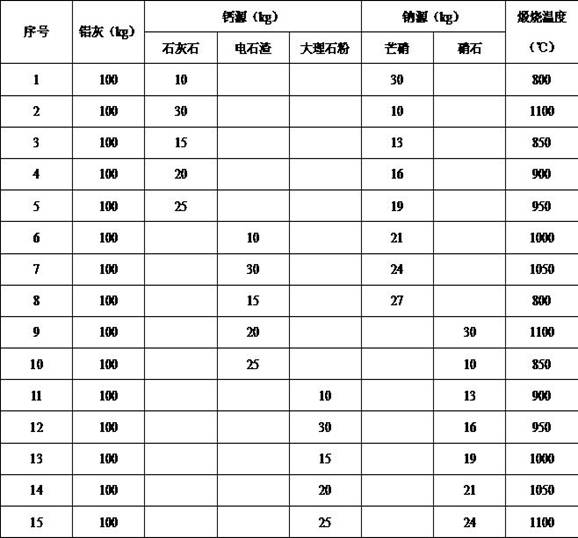

[0018] Adding calcium source and sodium source to aluminum ash, mixing evenly, calcining in a nitrider to obtain a flue gas purifying agent. The formula and calcination temperature of calcium source and sodium source are shown in Table 1.

[0019] Table 1

[0020]

[0021] Metal aluminum in aluminum ash is converted into aluminum nitride, and aluminum oxide is converted into calcium aluminate, and its conversion rate is 100%; all embodiments of the present invention can be implemented and can achieve the purpose of the invention. The present invention is not limited to these examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com