Flexible circuit board and manufacturing method thereof

A technology of flexible circuit boards and manufacturing methods, which is applied in the fields of printed circuit manufacturing, printed circuits, printed circuits, etc., can solve problems such as unsatisfactory requirements, and achieve the effect of improving visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

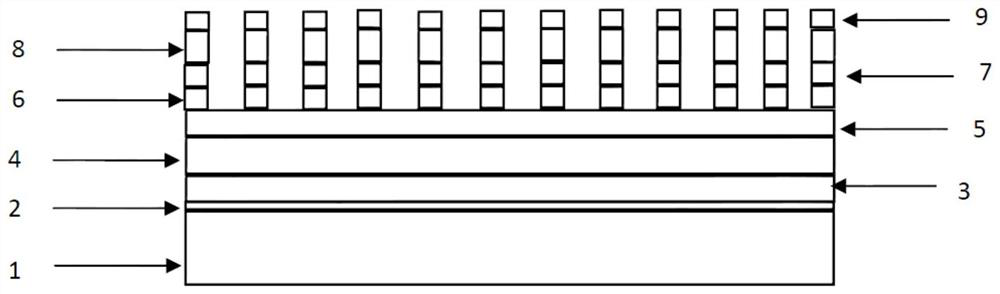

[0093] The flexible circuit board provided in this embodiment includes a flexible base material, and the material of the flexible base material is PET (transparent polyethylene resin), which is sequentially formed on the flexible base material from bottom to top;

[0094] a transition layer 2 with a thickness of 1 nm, made of simple silicon;

[0095] An optical anti-reflection layer 3 with a thickness of 15nm, made of silicon oxide;

[0096] The optical anti-reflection layer 4 with a thickness of 30nm is made of niobium oxide;

[0097] A protective transition layer 5 with a thickness of 5 nm, made of silicon oxide;

[0098] A transition layer 6 with a thickness of 5 nm, made of elemental nickel;

[0099] A seed layer 7 with a thickness of 20nm, made of simple copper;

[0100] Copper layer 8 with a thickness of 10 μm; and

[0101] The protective layer 9 with a thickness of 100 nm is made of simple nickel.

[0102] The preparation method comprises the following steps:

[0...

Embodiment 2

[0115] The flexible circuit board provided in this embodiment includes a flexible substrate, and the material of the flexible substrate is PI (transparent polyimide), which is sequentially formed on the flexible substrate from bottom to top;

[0116] A transition layer 2 with a thickness of 3nm, made of elemental zirconium;

[0117] The optical anti-reflection layer 3 with a thickness of 25nm is made of silicon nitride;

[0118] An optical anti-reflection layer 4 with a thickness of 60nm, made of silicon oxide;

[0119] A protective transition layer 5 with a thickness of 10 nm, made of silicon oxide;

[0120] The transition layer 6 with a thickness of 20nm is made of elemental silver;

[0121] A seed layer 7 with a thickness of 150nm, made of simple copper;

[0122] Copper layer 8 with a thickness of 25 μm; and

[0123] The protective layer 9 with a thickness of 1000nm is made of elemental silver.

[0124] The preparation method comprises the following steps:

[0125] A ...

Embodiment 3

[0137] The flexible circuit board provided in this embodiment includes a flexible substrate, and the material of the flexible substrate is PI (transparent polyimide), which is sequentially formed on the flexible substrate from bottom to top;

[0138] A transition layer 2 with a thickness of 5 nm, made of elemental chromium;

[0139] The optical anti-reflection layer 3 with a thickness of 50nm is made of silicon nitride;

[0140] The optical anti-reflection layer 4 with a thickness of 100nm is made of titanium oxide;

[0141] A protective transition layer 5 with a thickness of 200nm, made of silicon oxide;

[0142] The transition layer 6 with a thickness of 200nm is made of elemental gold;

[0143] A seed layer 7 with a thickness of 300nm, made of simple copper;

[0144] A copper layer 8 with a thickness of 35 μm, made of simple copper; and

[0145] The protective layer 9 with a thickness of 2000nm is made of simple tin.

[0146] The preparation method comprises the follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com