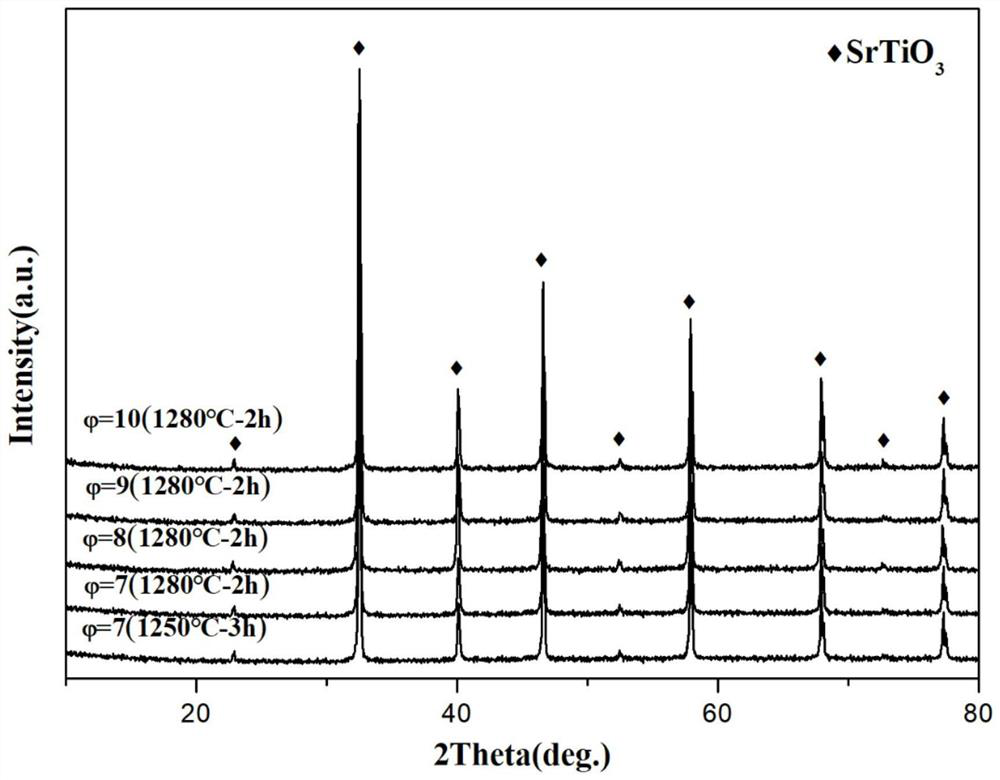

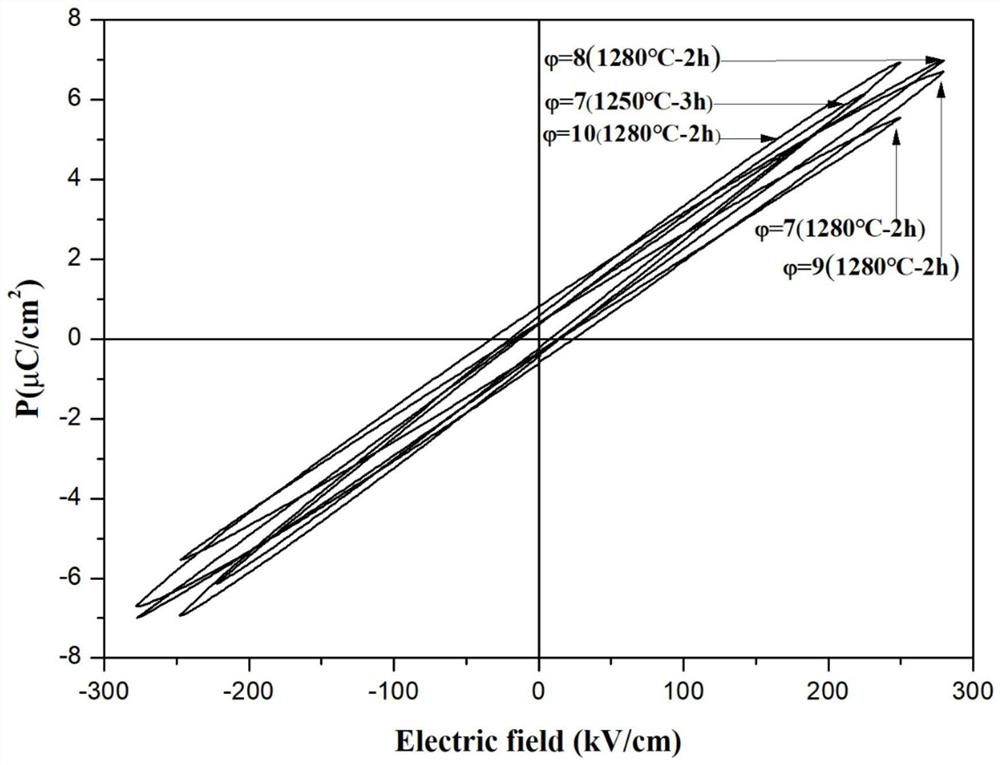

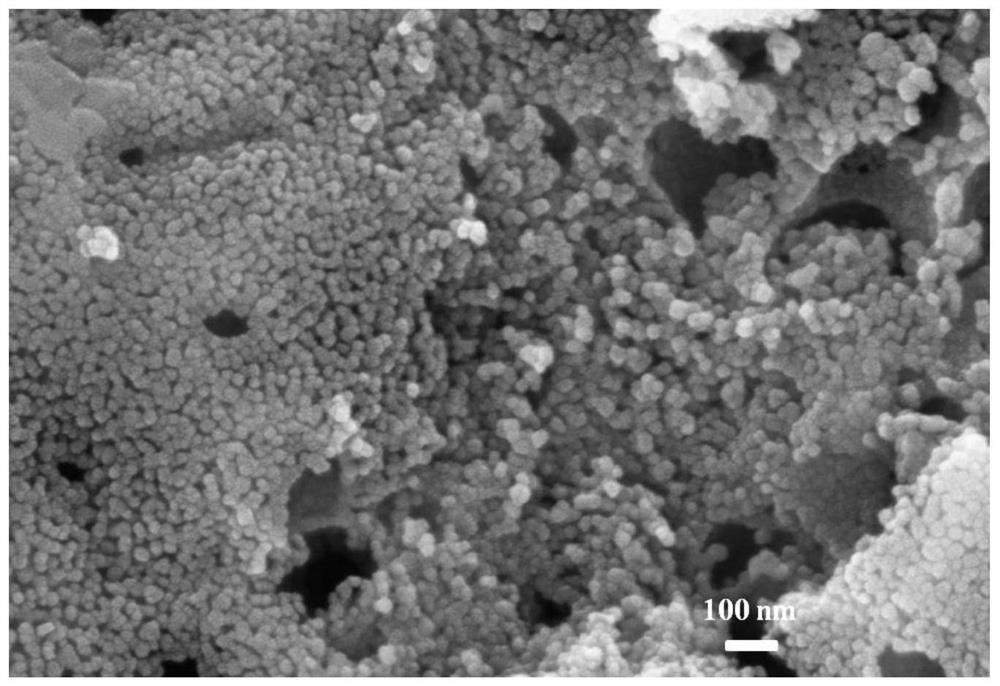

Preparation method of strontium titanate energy storage dielectric ceramic material with high breakdown and high energy storage density

A technology of high energy storage density and energy storage medium, applied in the field of ceramic dielectric energy storage material preparation, can solve the problems of coarse ceramic grains, high production cost, low breakdown strength, etc., and achieve the effect of fine and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Measure 7mL of butyl titanate with a purity of 99%, drop it into 100mL deionized water with slow stirring, and after the solution forms a white colloidal precipitate, add 18mL nitric acid dropwise into the solution and stir vigorously until it becomes white colloidal The precipitate dissolves completely to form TiO(NO 3 ) 2 clear solution;

[0032] Step 2: take by weighing glycine 23.68g (ie The value is 7) and strontium nitrate 4.29g is added to TiO(NO 3 ) 2 Mix the solution evenly to form a precursor solution, transfer the precursor solution to a 500ml beaker and use a universal furnace to heat, evaporate and concentrate until foaming and burning to obtain carbon-containing nano-SrTiO 3 Ceramic primary powder;

[0033] Step 3: the carbon-containing nano-SrTiO obtained in step 2 3 Put the ceramic primary powder into a muffle furnace at 650°C for 1.5 hours to remove carbon, and the nano-SrTiO after carbon removal 3 Add 0.2mL of PVA solution with a mass f...

Embodiment 2

[0035] Step 1: Measure 7mL of butyl titanate with a purity of 99%, drop it into 100mL deionized water with slow stirring, and after the solution forms a white colloidal precipitate, add 18mL nitric acid dropwise into the solution and stir vigorously until it becomes white colloidal The precipitate dissolves completely to form TiO(NO 3 ) 2 clear solution;

[0036] Step 2: take by weighing glycine 23.68g (ie The value is 7) and strontium nitrate 4.29g is added to TiO(NO 3 ) 2 Mix the solution evenly to form a precursor solution, transfer the precursor solution to a 500ml beaker and use a universal furnace to heat, evaporate and concentrate until foaming and burning to obtain carbon-containing nano-SrTiO 3 Ceramic primary powder;

[0037] Step 3: the carbon-containing nano-SrTiO obtained in step 2 3 Put the ceramic primary powder into a muffle furnace at 650°C for 1.5 hours to remove carbon, and the nano-SrTiO after carbon removal 3 Add 0.2mL of PVA solution with a mass f...

Embodiment 3

[0039] Step 1: Measure 7mL of butyl titanate with a purity of 99%, drop it into 100mL deionized water with slow stirring, and after the solution forms a white colloidal precipitate, add 18mL nitric acid dropwise into the solution and stir vigorously until it becomes white colloidal The precipitate dissolves completely to form TiO(NO 3 ) 2 clear solution;

[0040] Step 2: take by weighing glycine 27.07g (ie The value is 8) and strontium nitrate 4.29g is added to TiO(NO 3 ) 2 Mix the solution evenly to form a precursor solution, transfer the precursor solution to a 500ml beaker and use a universal furnace to heat, evaporate and concentrate until foaming and burning to obtain carbon-containing nano-SrTiO 3 Ceramic primary powder;

[0041] Step 3: the carbon-containing nano-SrTiO obtained in step 2 3 Put the ceramic primary powder into a muffle furnace at 650°C for 1.5 hours to remove carbon, and the nano-SrTiO after carbon removal 3 Add 0.2mL of PVA solution with a mass f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com