Method for one-step synthesis of iron fluoride/C positive electrode material

A technology of ferrous fluoride and cathode material, applied in battery electrodes, electrochemical generators, electrical components, etc., can solve the problems of complex process, environmental pollution, and many influencing factors, and achieve simple process, short holding time, avoidance of growing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The method for synthesizing nano-ferrous fluoride / C by one-step method described in this embodiment specifically comprises the following steps:

[0019] (1) Mix ferrous oxalate and powdered polytetrafluoroethylene evenly according to the mass ratio of ferrous oxalate and polytetrafluoroethylene at a ratio of 8:3, and then place it in an argon atmosphere at a heating rate of 8°C / min Rapidly raise the temperature to 650°C, keep the temperature for 2 hours, and cool down to room temperature with the furnace after the roasting is completed;

[0020] (2) Take out the product and grind and disperse to obtain nanometer ferrous fluoride / C positive electrode material powder.

[0021] Electrochemical performance test:

[0022] 1. the nano-ferrous fluoride / C powder obtained in step (2), and acetylene black, polyvinylidene fluoride (PVDF) are taken by weighing and placed in an agate mortar in a ratio of 8:1:1 by mass ratio, Add an appropriate amount of N-methyl-2-pyrrolidone (NMP...

Embodiment 2

[0026] The method for synthesizing nano-ferrous fluoride / C by one-step method described in this embodiment specifically comprises the following steps:

[0027] (1) Mix ferrous oxalate and powdered polytetrafluoroethylene evenly according to the mass ratio of ferrous oxalate and polytetrafluoroethylene at a ratio of 7:3, and then place it in an argon atmosphere at a heating rate of 9°C / min Rapidly raise the temperature to 550°C, keep the temperature for 1 hour, and cool down to room temperature with the furnace after the roasting is completed;

[0028] (2) Take out the product and grind and disperse to obtain nanometer ferrous fluoride / C positive electrode material powder.

[0029] Electrochemical performance test: assemble the nano-ferrous fluoride / C powder obtained in step (2) into a CR2025 button battery according to the method described in Example 1; test its charge and discharge performance after standing for 24 hours.

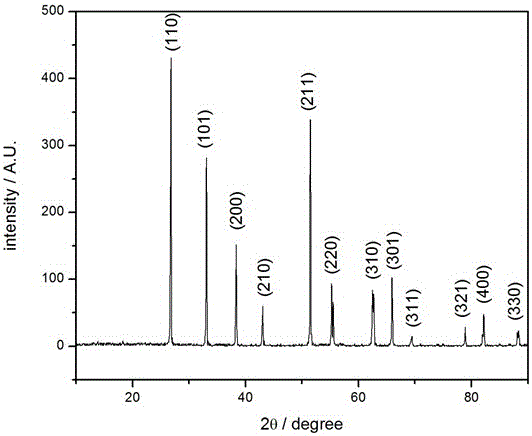

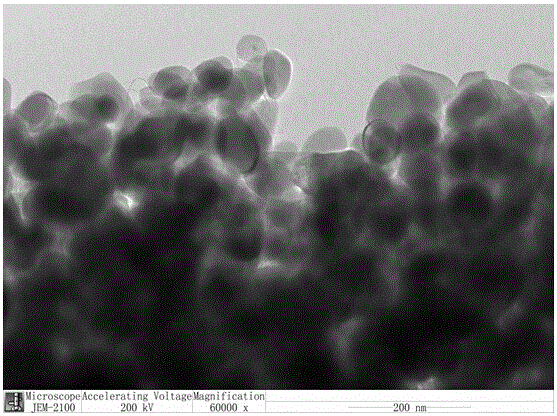

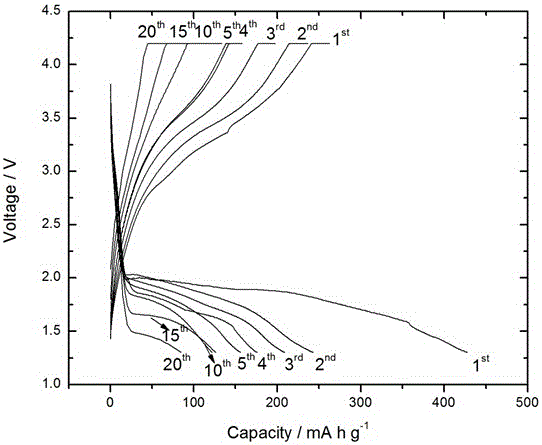

[0030] The XRD picture of the nanometer ferrous flu...

Embodiment 3

[0034] The method for synthesizing nano-ferrous fluoride / C by one-step method described in this embodiment specifically comprises the following steps:

[0035] (1) Mix ferrous oxalate and powdered polytetrafluoroethylene evenly according to the mass ratio of ferrous oxalate and polytetrafluoroethylene at a ratio of 10:3, and then place it in an argon atmosphere at a heating rate of 7°C / min Rapidly raise the temperature to 500°C, keep the temperature for 1.5h, and cool down to room temperature with the furnace after the roasting is completed;

[0036] (2) Take out the product and grind and disperse to obtain nanometer ferrous fluoride / C positive electrode material powder.

[0037] Electrochemical performance test: assemble the nano-ferrous fluoride / C powder obtained in step (2) into a CR2025 button battery according to the method described in Example 1; test its charge and discharge performance after standing for 24 hours.

[0038] The maximum discharge specific capacity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com