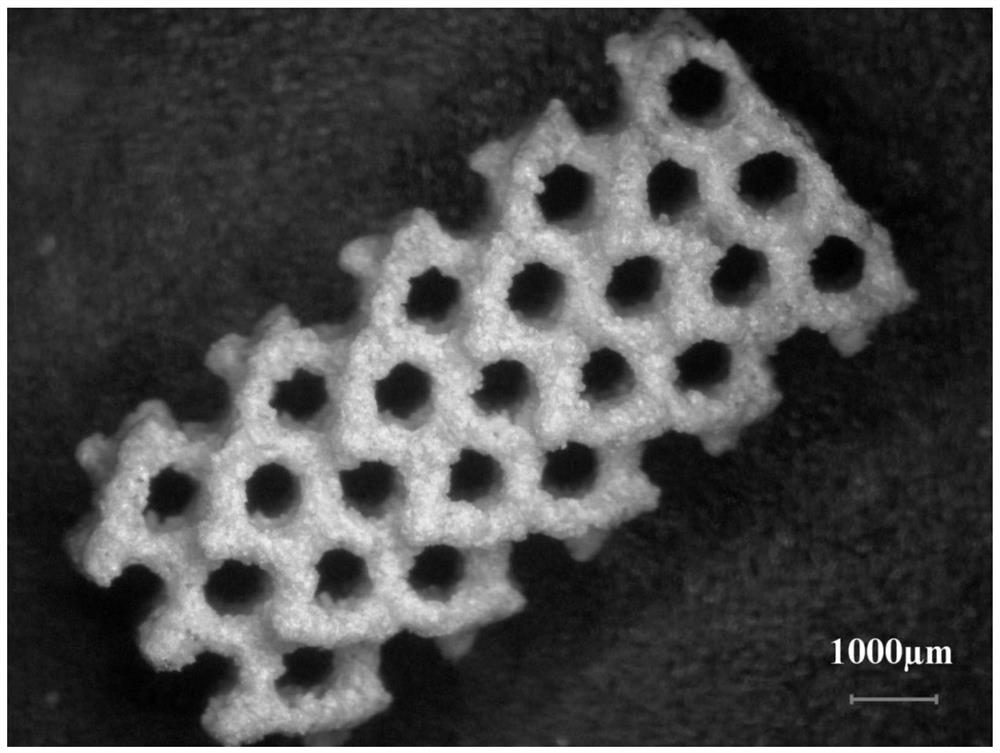

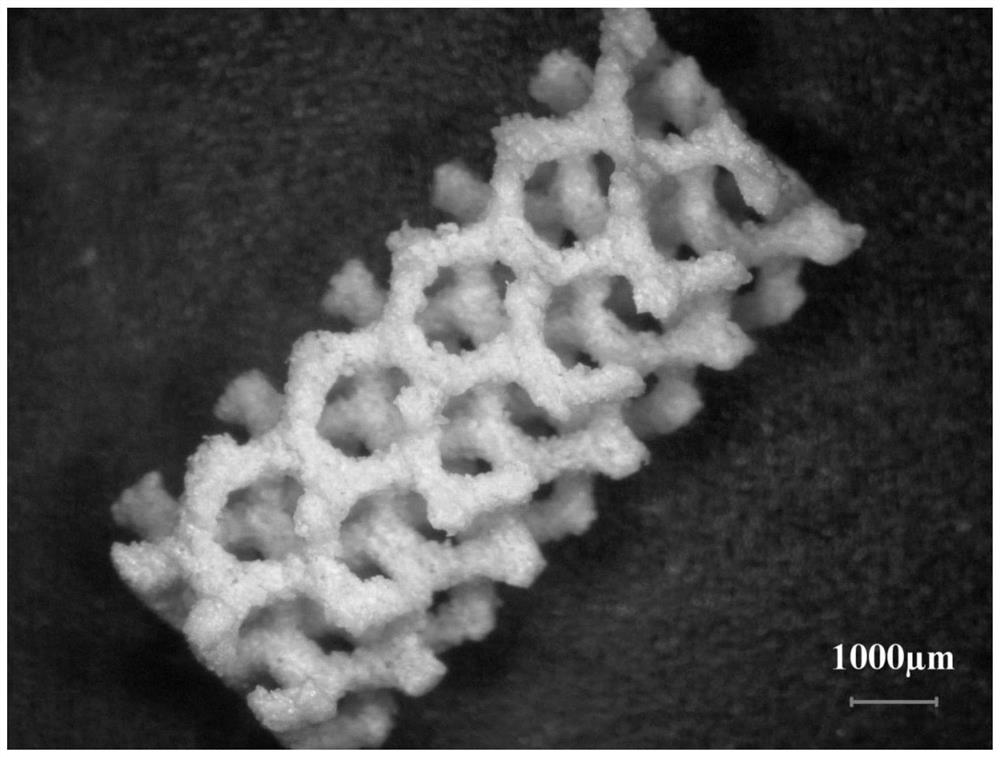

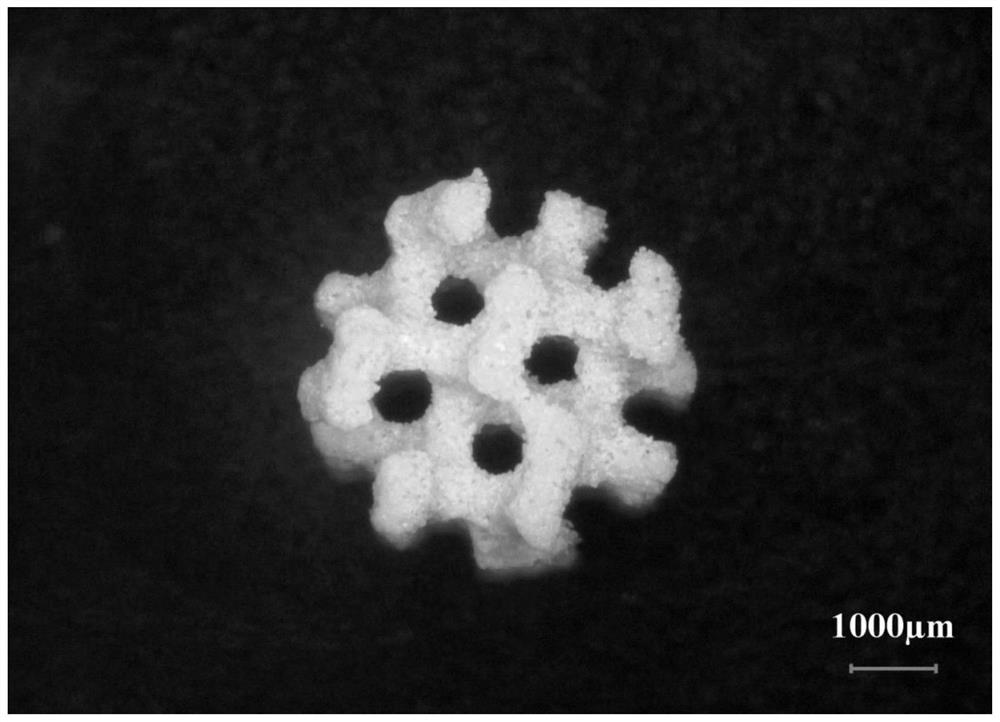

Forming method and product of polyetheretherketone biophilic metal porous bone implant

A polyether ether ketone and metal porous technology, which is applied in prosthesis, tissue regeneration, additive manufacturing, etc., can solve the problems of poor powder spreading effect, unclear outline, and difficult powder cleaning, etc., and achieves strong reproducibility and contour Clear, silky line resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Preparation of the mixed powder, 475 g of PEEK powder is mixed with 25 g Ta together, and the planetary ball mill is used in 300 r / min.

[0047] (2) Powder pretreatment, (A1) put the composite powder in the formation of the powder chamber and the molded chamber of the HT-SLS additive manufacturing equipment, open the 3DP process software, and set the pretreatment powder temperature of 250 ° C, pretreatment pre-paving The starting temperature is 290 ° C, the pretreatment pre-paving temperature is 300 ° C, the pre-paved time interval 15S, the powdering chamber heating power is 2500W, the infrared radiation efficiency is 0.5, the shaped cavity heating power is 2,300 W, the forming efficiency is 0.6; (a2) into argon Protective gas, heat the powder chamber, the molding chamber; (A3) After the release of the powder, the temperature remains at 300 ° C continues to continue drying 2h, shutting down the system, making the powder naturally cooled to room temperature;

[0048] (...

Embodiment 2

[0051] The present embodiment is mainly different from the first embodiment in that the weight percentage of the PEEK powder is different, and the pre-shutdown temperature and the processing temperature are different, the pre-shutdown temperature is 310 ° C, the processing temperature is 320 ° C, which is specifically as described below.

[0052] (1) Preparation of the mixed powder, 475 g of PEEK powder is mixed with 25 g Ta together, and the planetary ball mill is used in 300 r / min.

[0053] (2) Powder pretreatment, (A1) put the composite powder in the formation of the powder chamber and the molded chamber of the HT-SLS additive manufacturing equipment, open the 3DP process software, and set the pretreatment powder temperature of 250 ° C, pretreatment pre-paving The starting temperature is 290 ° C, the pretreatment pre-paving temperature is 300 ° C, the pre-paved time interval 15S, the powdering chamber heating power is 2500W, the infrared radiation efficiency is 0.5, the shape...

Embodiment 3

[0057] The present embodiment is mainly different from the first embodiment in that the weight percentage of the PEEK powder is different, and the pre-shutdown temperature and processing temperature are different, the pre-shutdown temperature is 305 ° C, the processing temperature is 315 ° C, which is specifically as described below.

[0058] (1) Preparation of the mixed powder, 475 g of PEEK powder is mixed with 25 g Ta together, and the planetary ball mill is used in 300 r / min.

[0059] (2) Powder pretreatment, (A1) put the composite powder in the formation of the powder chamber and the molded chamber of the HT-SLS additive manufacturing equipment, open the 3DP process software, and set the pretreatment powder temperature of 250 ° C, pretreatment pre-paving The starting temperature is 290 ° C, the pretreatment pre-paving temperature is 300 ° C, the pre-paved time interval 15S, the powdering chamber heating power is 2500W, the infrared radiation efficiency is 0.5, the shaped ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com