Stress corrosion sensitivity prediction method for shell-and-tube heat exchanger tube and tube plate welded joint

A technology for shell-and-tube heat exchangers and tube-sheet welding, which is used in instruments, special data processing applications, electrical digital data processing, etc. Stress distribution and other issues to achieve the effect of ensuring correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] (1) Determine the geometric dimensions of the welded joints between the tube and tube sheet of the shell-and-tube heat exchanger.

[0048] (2) Determine the material parameters of the heat exchanger tube head that change with temperature, including: elastic modulus, Poisson's ratio, yield strength, thermal conductivity coefficient, thermal expansion coefficient, specific heat, and density.

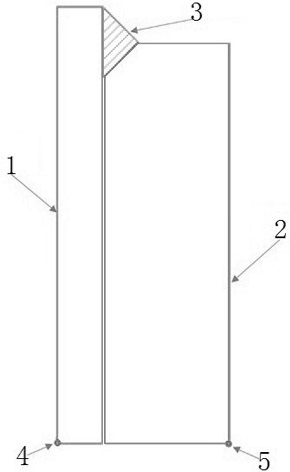

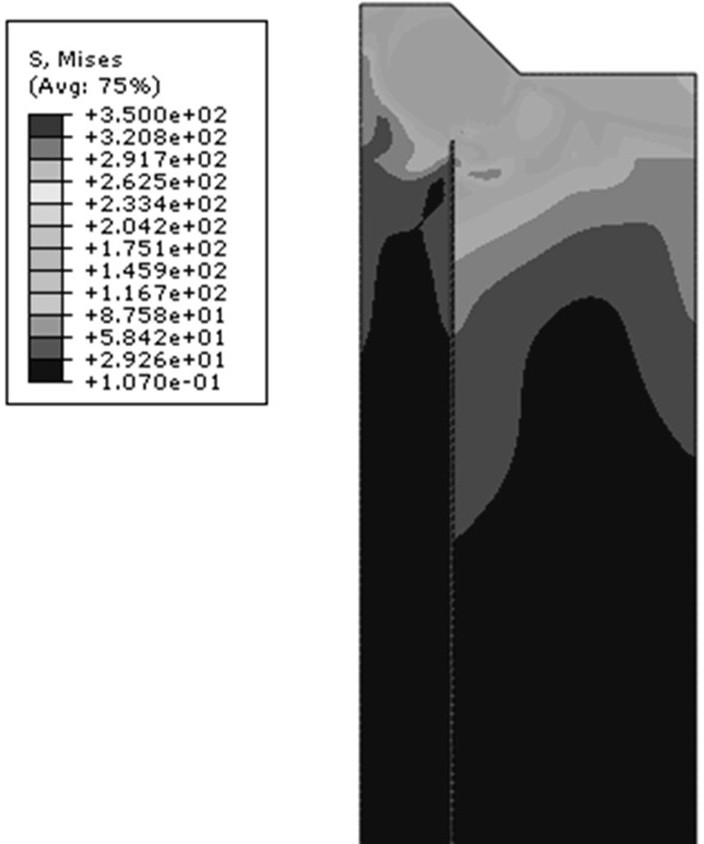

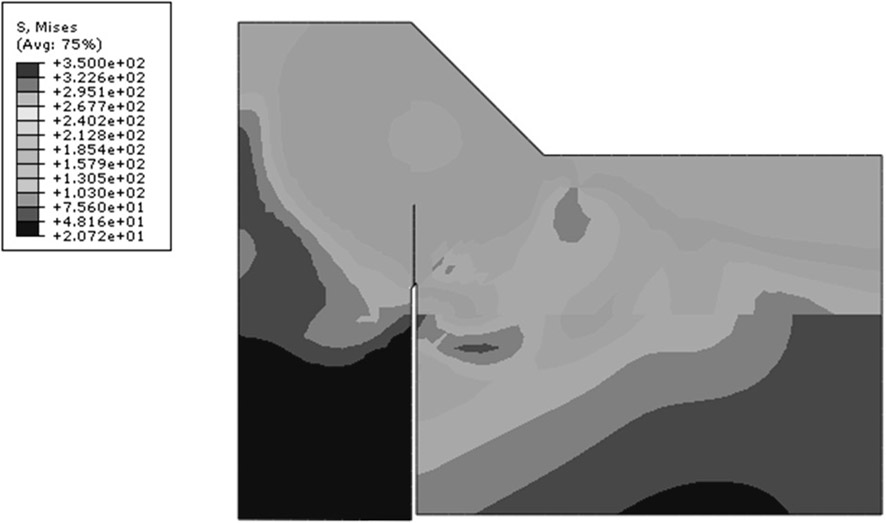

[0049] (3) In order to improve the calculation efficiency, the two-dimensional axisymmetric finite element model of the welded joint between the tube and tube sheet of the shell-and-tube heat exchanger was established by using the ABAQUS finite element software, as shown in figure 1 shown. Set the boundary constraint conditions of the tube head of the shell-and-tube heat exchanger. The heat exchange tube is set at the end point I of the tube to be axisymmetrically constrained in the X direction, and the tube sheet is set at the end point II of the plate to be axisymmetrically const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com