Preparation method and application of manganese oxide octahedral molecular sieve catalyst

An octahedral molecular sieve and catalyst technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of harsh technical conditions for photoactivated persulfate and high energy consumption of thermally activated persulfate technology, Achieve good catalytic degradation effect, excellent catalytic effect, good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] First MnCO 3 (100g, 0.87mol) and potassium oxalate (10g, 0.054mol) were ground evenly in an agate mortar. Then the mixture was calcined in a muffle furnace at 400°C, 450°C, and 500°C for 2h to obtain solid samples (containing MnOx intermediates). The solid sample was then dispersed in a solution of concentrated nitric acid (30 mL) (16 mol / L) and potassium nitrate (10 g, 0.1 mol), and stirred and refluxed at 100° C. for 2 h. Finally, after filtering, washing with water three times, and drying at 80°C for 5 hours, the catalyst OMS-2-CA-x was obtained, where x represents the calcination temperature, including 400°C, 450°C, and 500°C.

[0041] Take manganese oxide octahedral molecular sieve (OMS-2) as a comparative case. The specific preparation method is to add potassium permanganate (5.89g) into a 250ml round bottom flask, then add 100ml of water, stir at room temperature for 10min, then continue to add 3ml of concentrated nitric acid (16mol / L) and 8.8g of manganese sul...

Embodiment 2

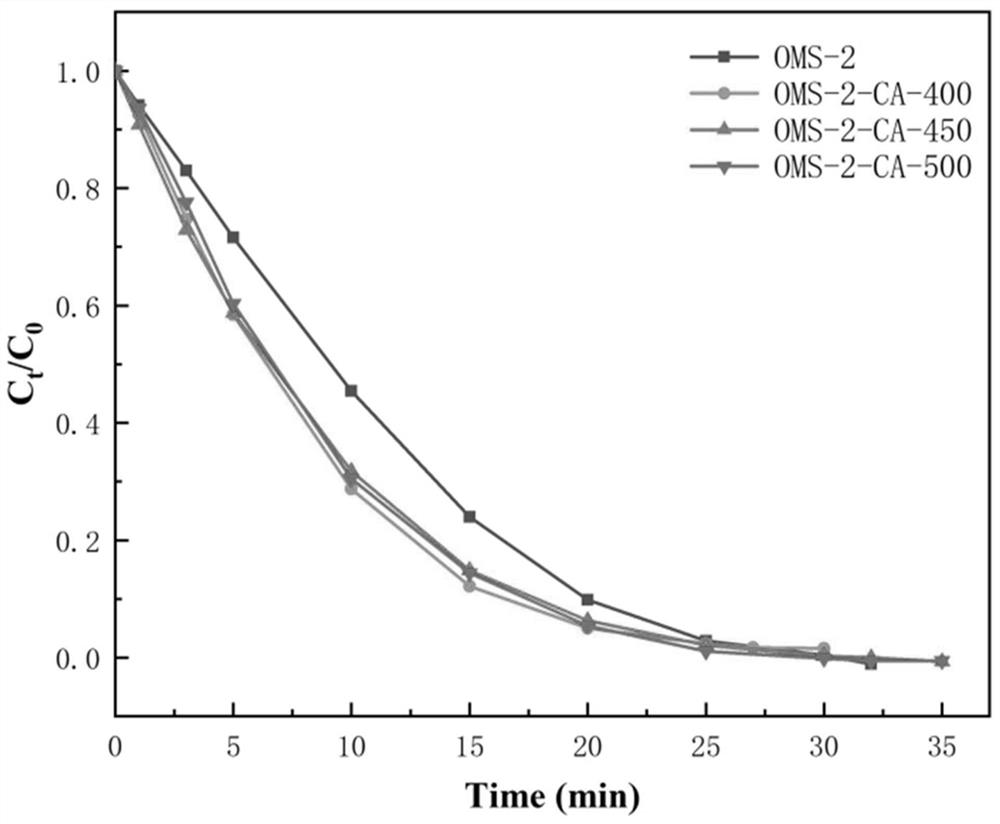

[0043] Using the OMS-2-CA-x prepared in Example 1 to catalyze PMS at different calcination temperatures to generate active oxygen species to degrade the application comparison chart on Rhodamine B, thereby selecting OMS-2-CA-450 as the optimal catalyst for degradation experiments .

[0044] The steps of the OMS-2-CA-x in catalyzing PMS to generate active oxygen species to degrade Rhodamine B are as follows:

[0045] Step 1: Add Rhodamine B solution (50mL, 20mg / L) into a 100mL round bottom flask, add OMS-2-CA-x (0.1g / L) and stir for 10min;

[0046] Step 2: Test and record the peak absorption of Rhodamine B at this time;

[0047] Step 3: Quickly add PMS (0.25g / L) to the round bottom flask, take out 3mL and add it to the cuvette at a certain interval, measure the peak shape of the Rhodamine B UV-Vis absorption spectrum with a UV-Vis photometer .

[0048] The quality of the OMS-2-CA-x catalyst described in step 3 is 12.5 mg.

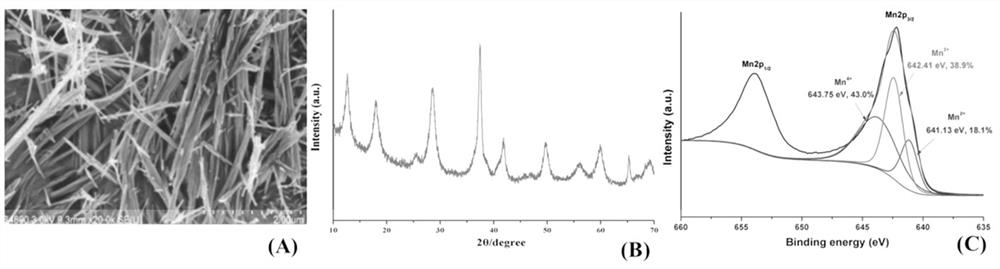

[0049] figure 1 For the SEM, XRD and XPS figures ...

Embodiment 3

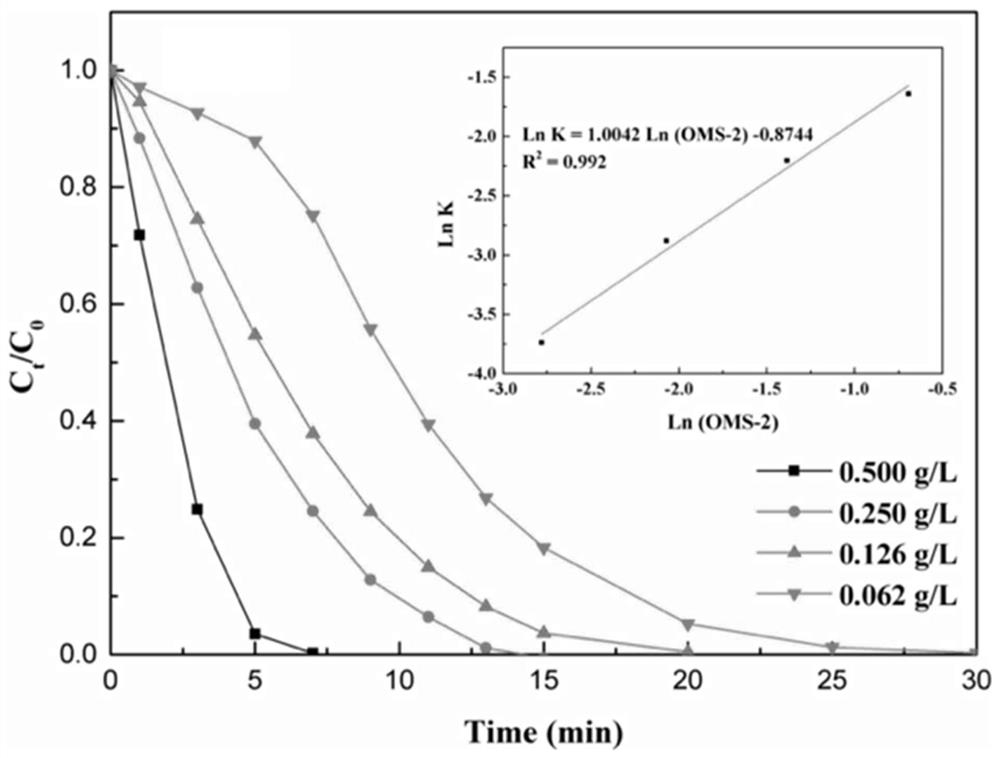

[0052] Using the OMS-2-CA-x prepared in Example 1 at the optimal calcination temperature, the catalyst takes different amounts to catalyze PMS to generate active oxygen species to degrade the application comparison chart on Rhodamine B, thereby selecting OMS-2-CA The amount of -450 was 0.25g / L as the optimum catalyst amount for the experiment of degrading other dyes.

[0053] The steps of the OMS-2-CA-450 in catalyzing PMS to generate active oxygen species to degrade Rhodamine B are as follows:

[0054] Step 1: Add Rhodamine B solution (50mL, 20mg / L) into a 100mL round bottom flask, add OMS-2-CA-450 (0.062g / L-0.5g / L) and stir for 10min;

[0055] Step 2: Test and record the peak absorption of Rhodamine B at this time;

[0056] Step 3: Quickly add PMS (0.25g / L) to the round bottom flask, take out 3mL and add it to the cuvette at a certain interval, measure the peak shape of the Rhodamine B UV-Vis absorption spectrum with a UV-Vis photometer .

[0057] The quality of the OMS-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com